A kind of prefabricated hollow composite beam and the cast-in-place construction method of beam and prefabricated slab

A technology of prefabricated slabs and superimposed beams, applied in joists, girders, trusses, etc., can solve the problems of easy oxidation of metal materials of joints, large amount of steel used for joints of beams, structural limitations of beam heights, etc., so as to facilitate the reduction of concrete , The effect of improving strength and improving load capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with accompanying drawing description and specific embodiment:

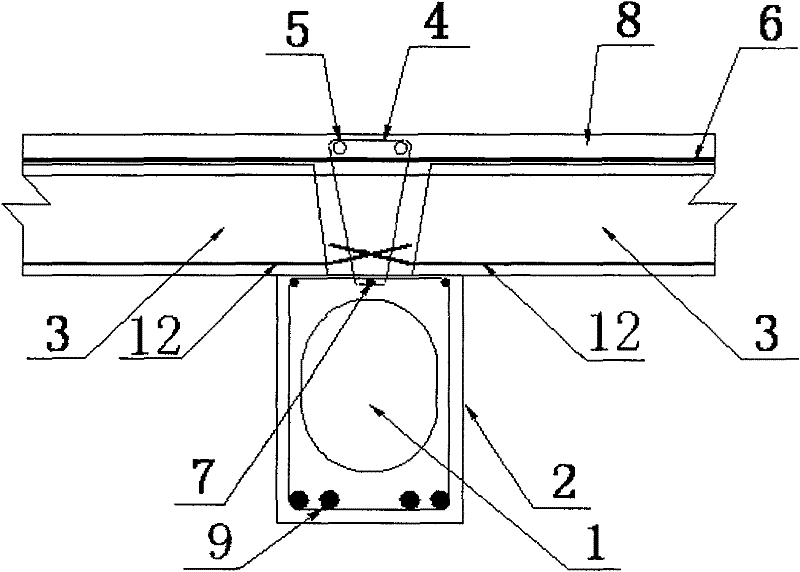

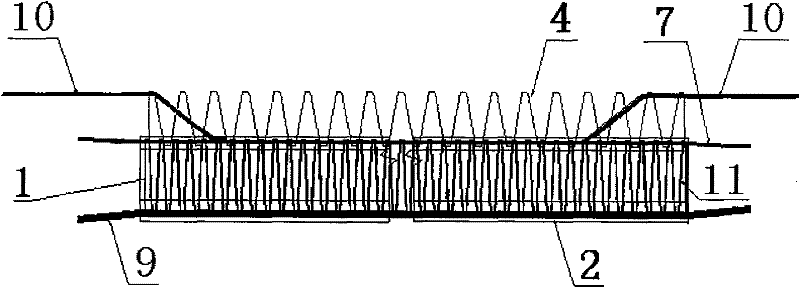

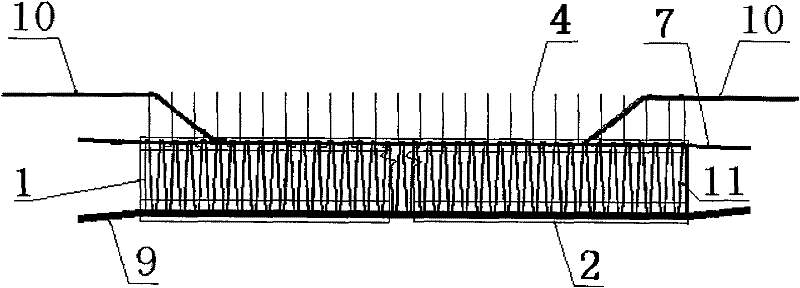

[0026] see figure 1 , figure 2 , image 3 , a prefabricated hollow composite beam of the present invention, which is prefabricated by steel bars and concrete, a through hole 1 is provided in the center of the section of the beam body 2, and a Vertical fibers 4 connected by ribs 7 .

[0027] The through hole 1 is a round hole or a waist circular hole arranged along the height direction of the beam body 2, so as to reduce the physical space of the neutral axis of the beam body 2 as much as possible, and the cross-sectional area of the through hole 1 is generally 1 / 3-2 / 3 of the cross-sectional area of body 2. The through hole 1 on the beam body 2 can reduce the self-weight to the greatest extent so as to improve the load capacity and reduce the proportion of invalid materials.

[0028] Such as figure 1 , image 3 As sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com