Barrel type handle lock

A handle lock and cylinder type technology, which is applied in the field of handle locks, can solve the problems of inconvenient installation and adjustment, large handle volume, complex structure, etc., and achieve good opening and reset functions, convenient installation and disassembly, and small swing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

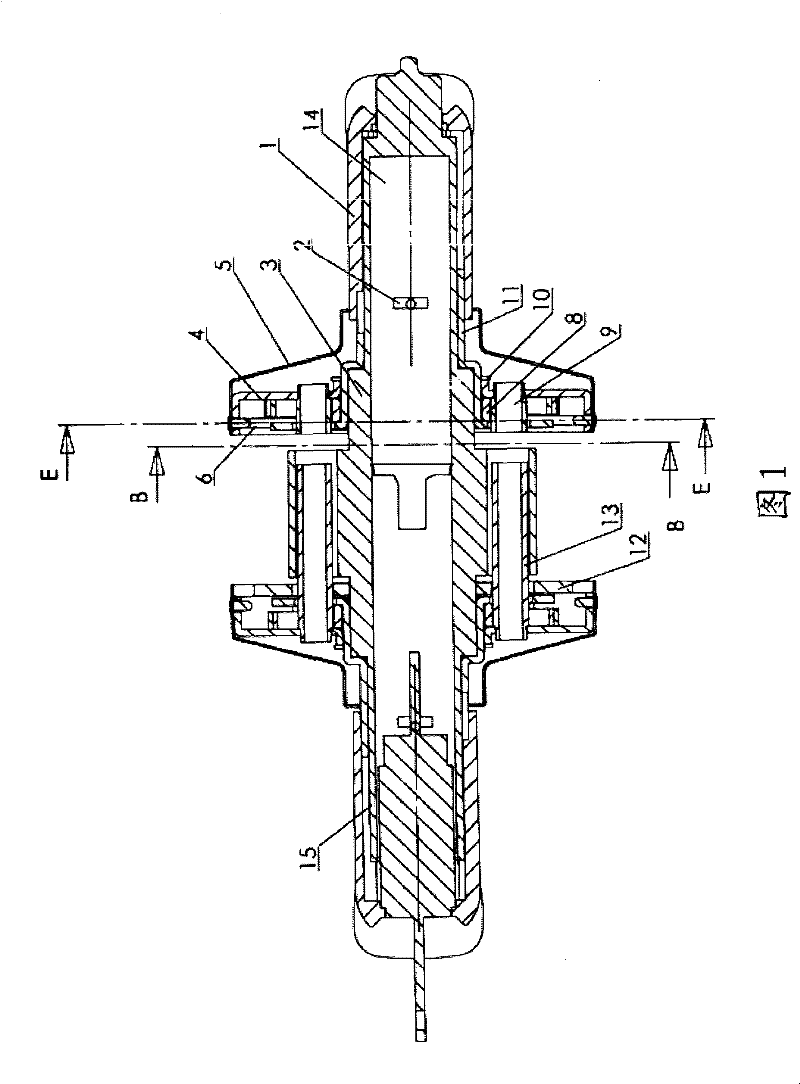

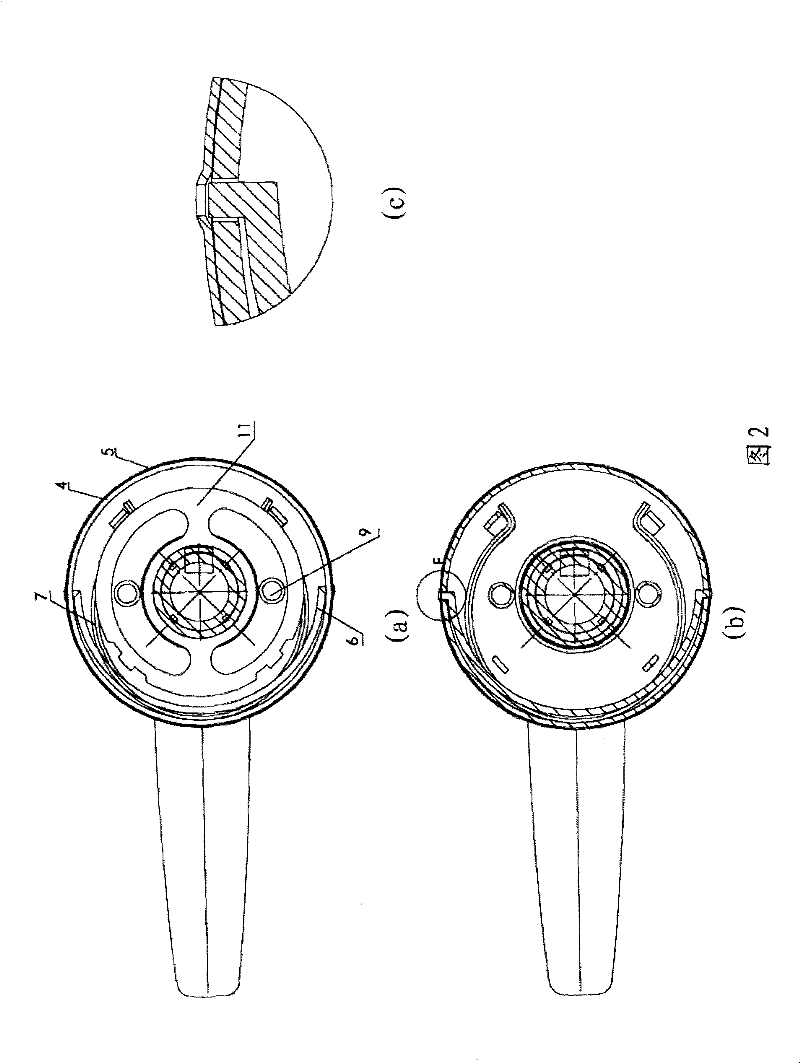

[0015] Specific embodiments of the lock according to the present invention will be described in more detail below with reference to the accompanying drawings.

[0016] Specifically, the present invention improves the handle lock cover assembly on the basis of the handle lock. The handle lock includes a front pass 15 and a rear pass 14 , as well as a front cover assembly and a rear cover assembly, and the front cover assembly and the rear cover assembly are fixedly installed through studs 13 .

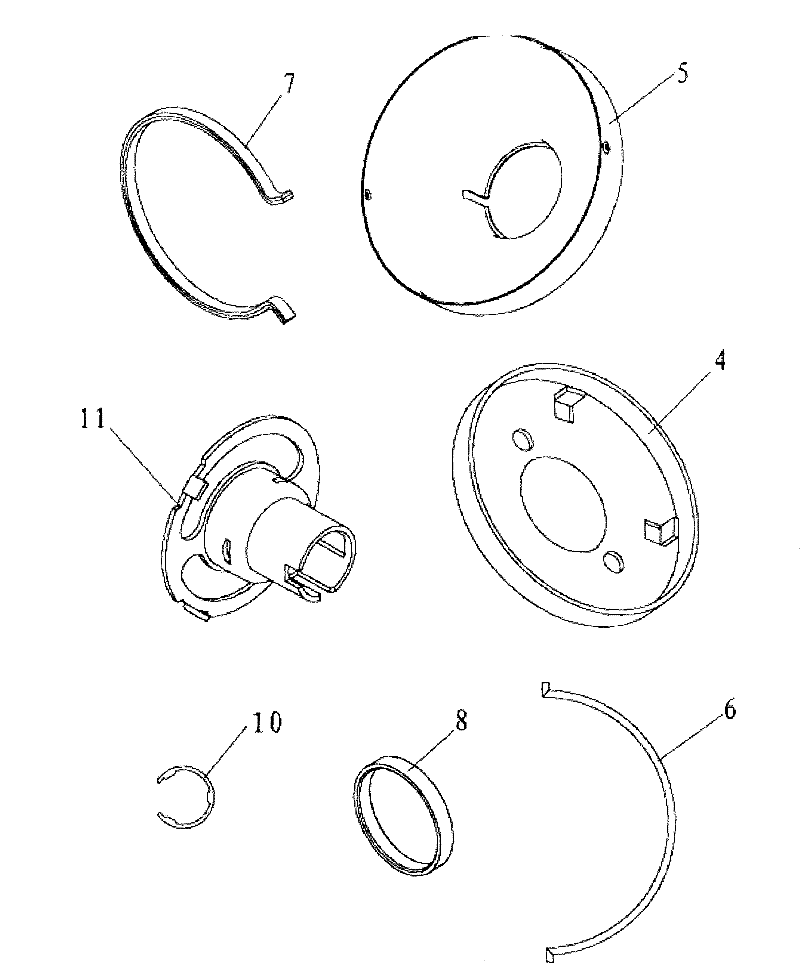

[0017] It can be seen from Fig. 1 and Fig. 2 that the tailgate assembly includes a turret 11 set on the lock body 3, a decorative cover 5 set on the turret 11, and a cover set on the outside of the turret 11 and inside the decorative cover 5. 4. The positioning spring 6 located at the lower part of the cover 4 and mounted on the decorative cover 5 in an engaging manner, the return spring 7 arranged inside the cover 4, and the limit sleeve 8 set on the outside of the turret 11 are locate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com