Handheld rotary cutter

A rotary cutting and rotary ground technology, applied in metal processing and other directions, can solve problems affecting user comfort, strain or other diseases, and achieve the effect of improving ergonomic design and increasing comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

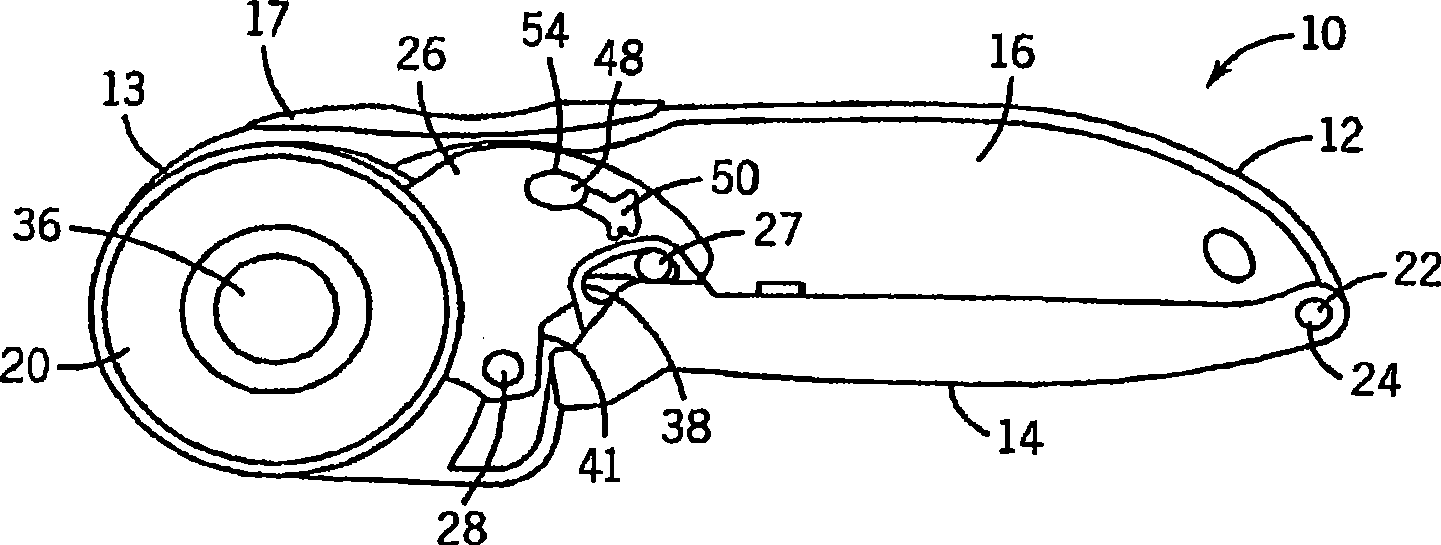

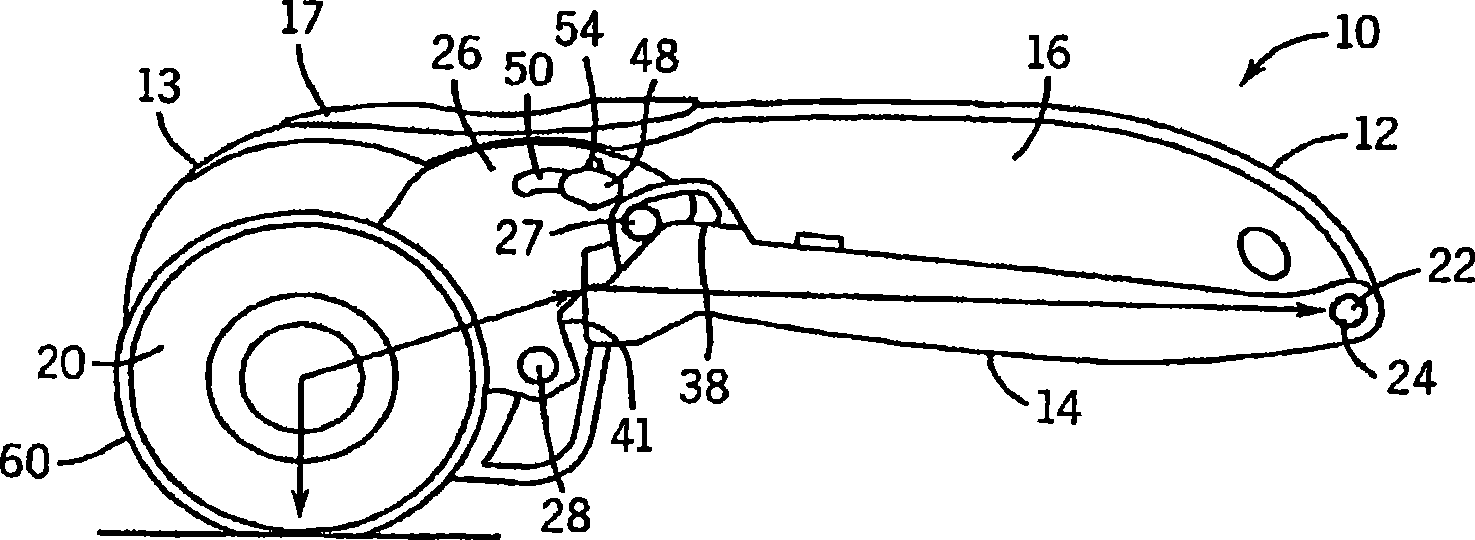

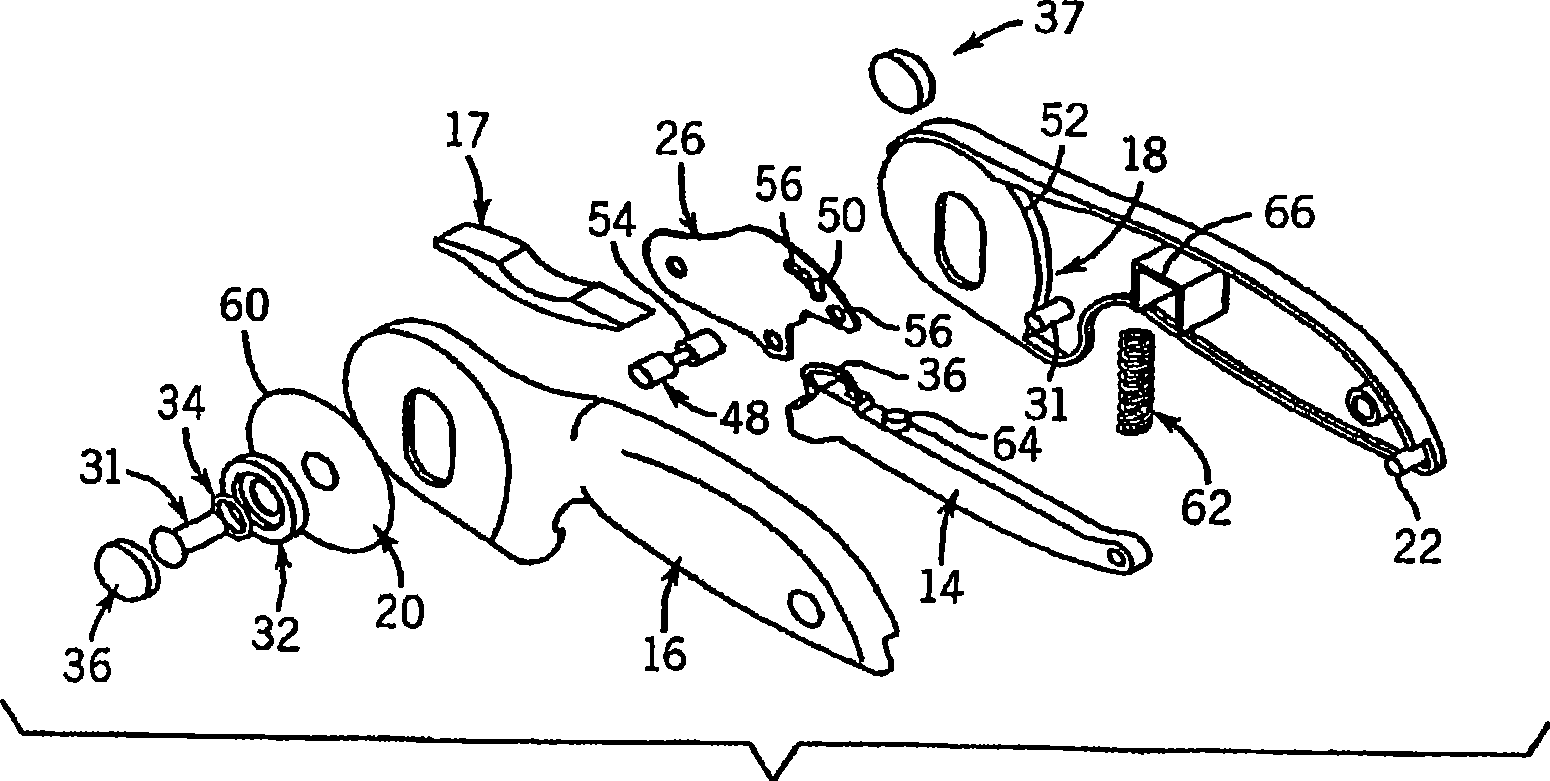

[0016] Figures 1 to 3 A rotary cutter 10 constructed in accordance with the principles of the present invention is shown. The rotary cutter 10 includes a body 12 having a cylindrical head 13 . Body 12 may take various forms. For example, body 12 may include separable but substantially identical right handle 16 and left handle 18 that may be disposed around blade 20 or both disposed on one side of blade 20 and partially connected by handle insert 17 . Those skilled in the art will also appreciate that other arrangements and configurations of the body 12 are possible.

[0017] Trigger 14 is rotatably coupled to body 12 at rear pivot point 22 . in such as Figures 1 to 3 In the embodiment shown, this is accomplished by coupling the trigger 14 to the body 12 using a plastic or metal rear pivot pin 24 .

[0018] In addition to the trigger 14 , a blade actuator 26 is also rotatably coupled to the body 12 . Such as figure 1 and 2 As shown, in various embodiments of the inven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com