Shaft seal packing and shaft seal structure for valve

A gasket and shaft seal technology, which is applied in the field of valve shaft seal structure, can solve the problems of disappearance of gap S, difficulty in obtaining self-sealing, limited tightening effect, etc., and achieve the effect of improving sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

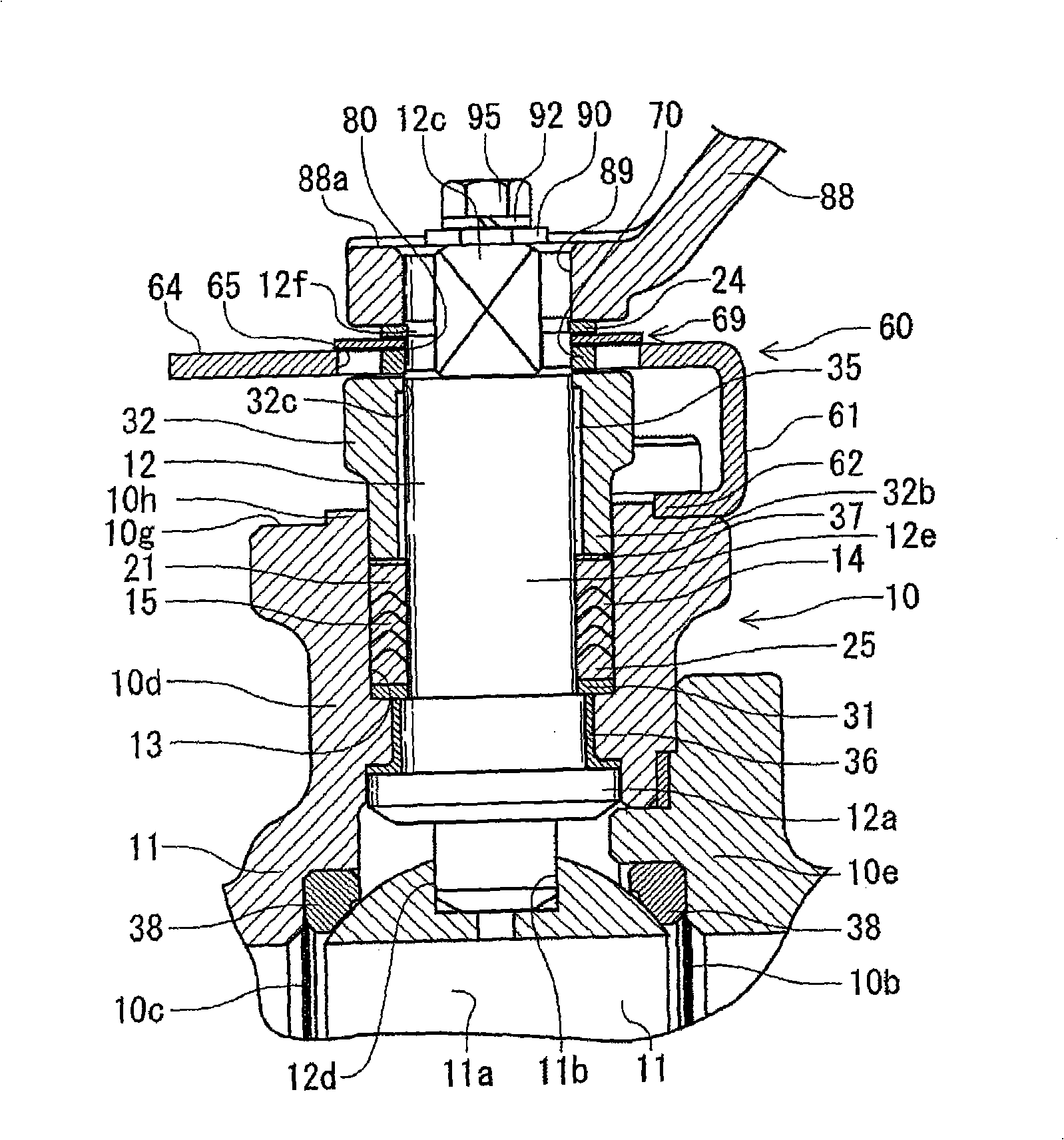

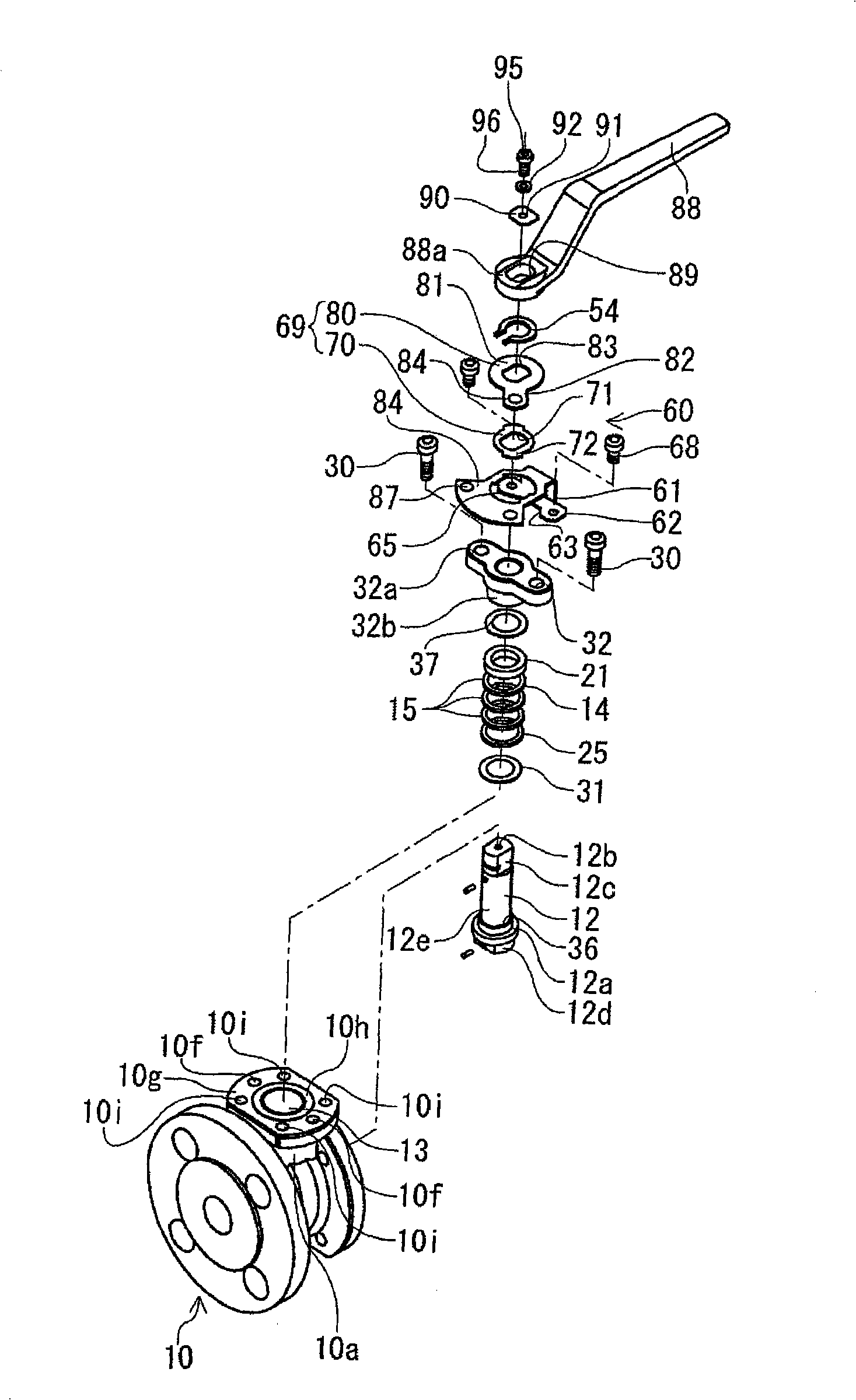

Embodiment 1

[0203] In order to set the peak side angle θ of the shaft seal gasket of the present invention 1 , and valley side angle θ 2 , the test of the sealing face pressure of the gasket body using different cone angles was carried out.

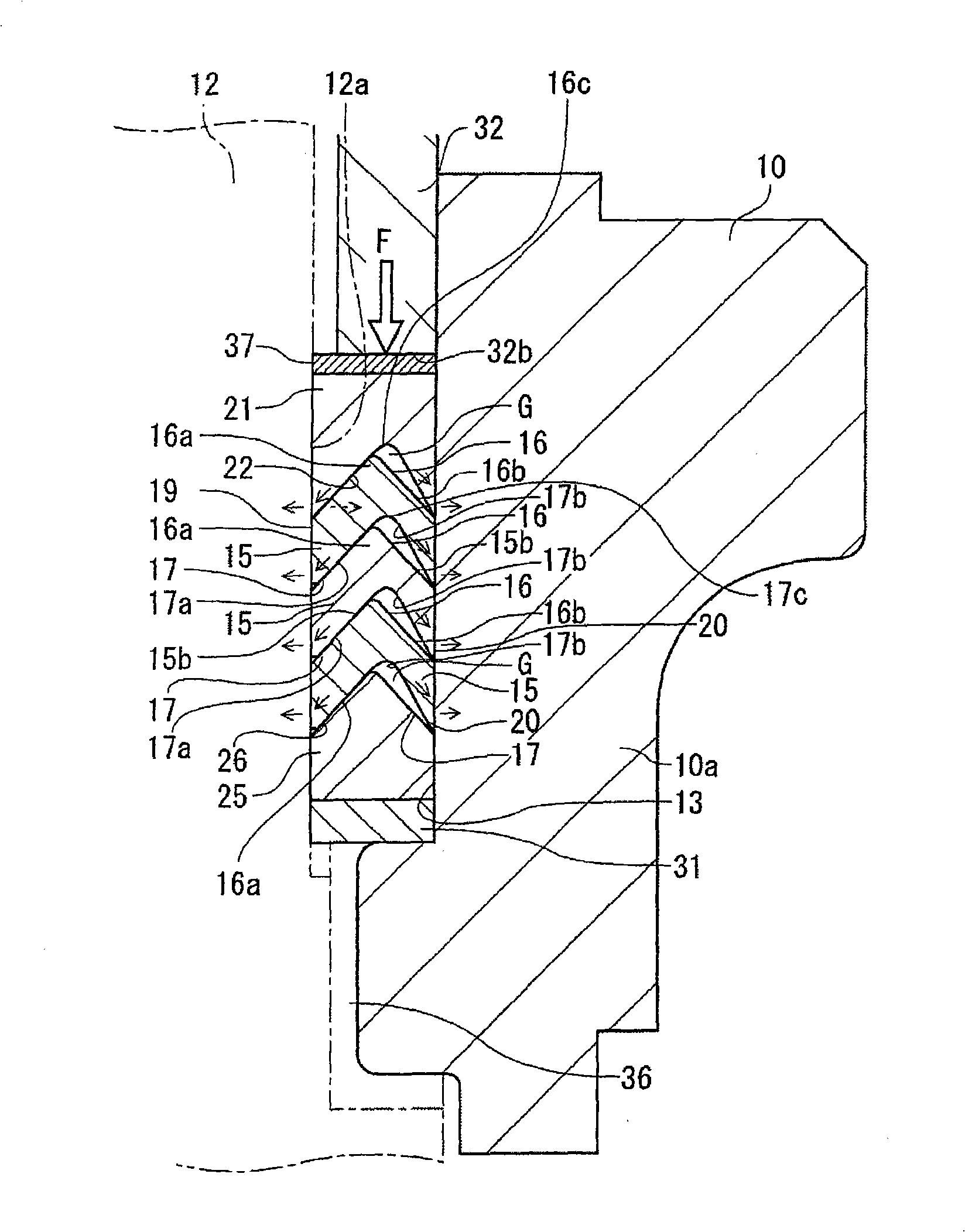

[0204] The valve of the test product is a 10K stainless steel suspension ball valve with a size of 50A. In addition, the shaft seal gasket has a structure in which 5 rings are laminated, and is made of PTFE (inner diameter φ22mm x outer diameter φ30mm x height 13.5mm), and has a symmetrical V-shaped cross section.

[0205] If the ring width of the main body of the gasket is W, and the height (sealing height) of the vertical surface connecting the upper lamination surface 16 and the lower lamination surface 17 is t, then there is a relationship of t=0.45W, and the sealing air of the bolt and nut can be measured. The minimum tightening torque at a pressure of 0.6MPa is measured for the sealing surface pressure.

[0206] For each test product, the an...

Embodiment 2

[0213] Next, a stress relaxation test was performed on the shaft seal gasket of the present invention.

[0214] As the test valve, the nominal pressure is 10K, the size of the ball valve is 50A, and the material of the ball valve body is SCS13A.

[0215] The size of the shaft seal gasket is φ22(mm)×φ32(mm)×11.5(mm) when the inner diameter×outer diameter×integrated together. Pad body in image 3 Make peak side angle θ 1 is 48°, so that the valley side angle θ 2 39°, in a state where two of the gasket main bodies are overlapped, the top adapter and the bottom adapter corresponding thereto are vertically attached.

[0216] On the other hand, as a comparative example, such as Figure 16 As shown, the peak side taper angle α'=(95 / 2)=47.5° of the gasket main body 101 is set, and the valley side taper angle β'=(90 / 2)=45° is set. In the same state (not shown), the upper adapter 102 and the lower adapter 103 corresponding thereto are installed up and down to form the V-shaped pack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com