OPC method for mask preparation course in semiconductor manufacturing process

A semiconductor and process technology, applied in the field of optical approximation correction, can solve problems such as difficulty in obtaining images and smaller process windows, and achieve the effects of improving mutual conflicts, expanding process windows, and avoiding possibilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

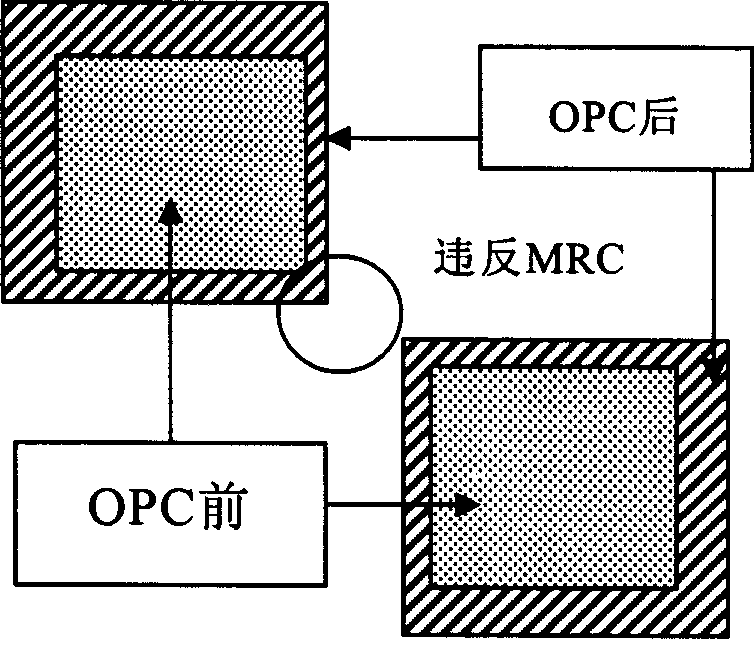

[0045] Before prior art OPC for square via pattern, as in Figure 4 As shown, the shape of the square connecting hole is changed into an octagon with eight sides of a to h, the length of the truncated side is controlled to be 1 / 4 of the side length of the square pattern, and the internal angles of the octagon are 135°. The octagon is then targeted for prior art OPC. After the OPC is done, the pattern obtained is exposed to the wafer to obtain an approximate circle, which is inscribed with the octagon before OPC in the prior art. The advantages of the present invention are explained below by describing the process of performing OPC of the prior art on the octagon.

[0046] First of all, through this solution, the existing OPC oscillation and convergence problems are improved.

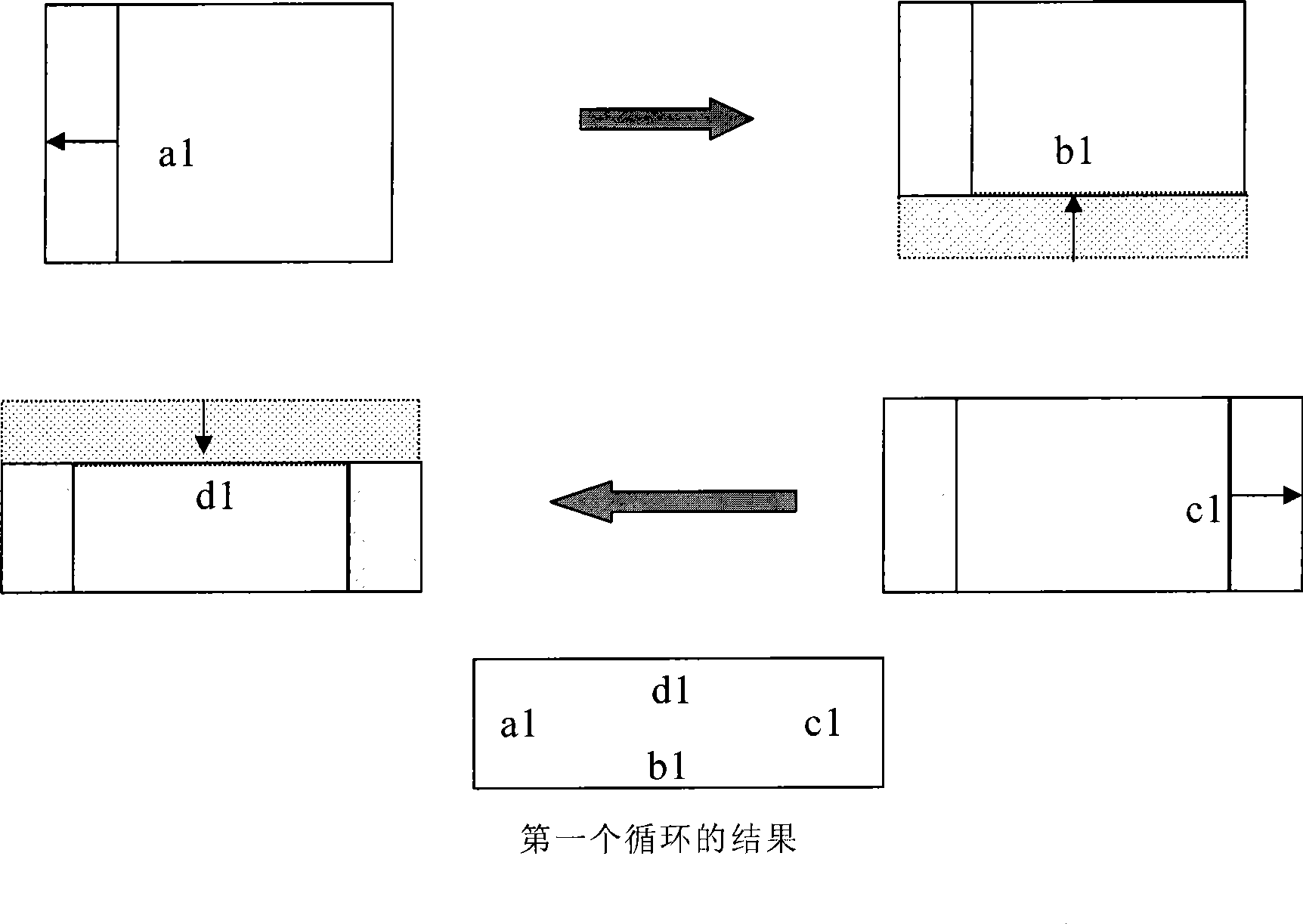

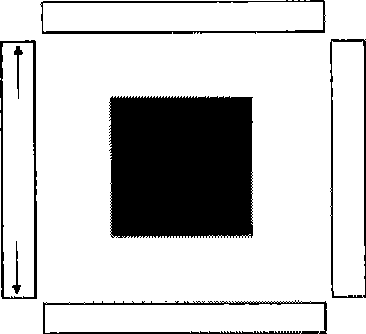

[0047] After the square connection hole is changed to an octagon, the steps of OPC in the prior art are carried out with the octagon as the target. Figure 5 As shown in the figure, arrows are used t...

Embodiment 2

[0063] Such as Figure 12 As shown, the shape of the square connection hole is modified to an equilateral 16-sided shape, where the 16-sided shape has four vertices located at the midpoints of the four sides of the original square. The 16-gon is then targeted for state-of-the-art OPC. In this way, an approximate circle is obtained when exposed to the wafer, and the approximate circle is inscribed with the 16-gon before OPC.

[0064] This modification greatly improves the OPC that only uses the prior art, and the principle is the same as that of the first embodiment. The experimental data of improving the process window of the regular polygon and the hexagonal connecting hole is given here. As shown in Table 2, for different lithographic focal depths, the 16-gon is within the allowable error requirement within a larger lithographic focal depth range relative to the square, that is, the 16-gon has better process window.

[0065] Table 2

[0066] Photolithography f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com