Gas sensor chip and gas sensor provided therewith

A gas sensor and chip technology, applied in the direction of material thermal conductivity, material resistance, etc., can solve problems such as short maintenance of sensors, achieve stable output characteristics, improve durability, and reduce the frequency of maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

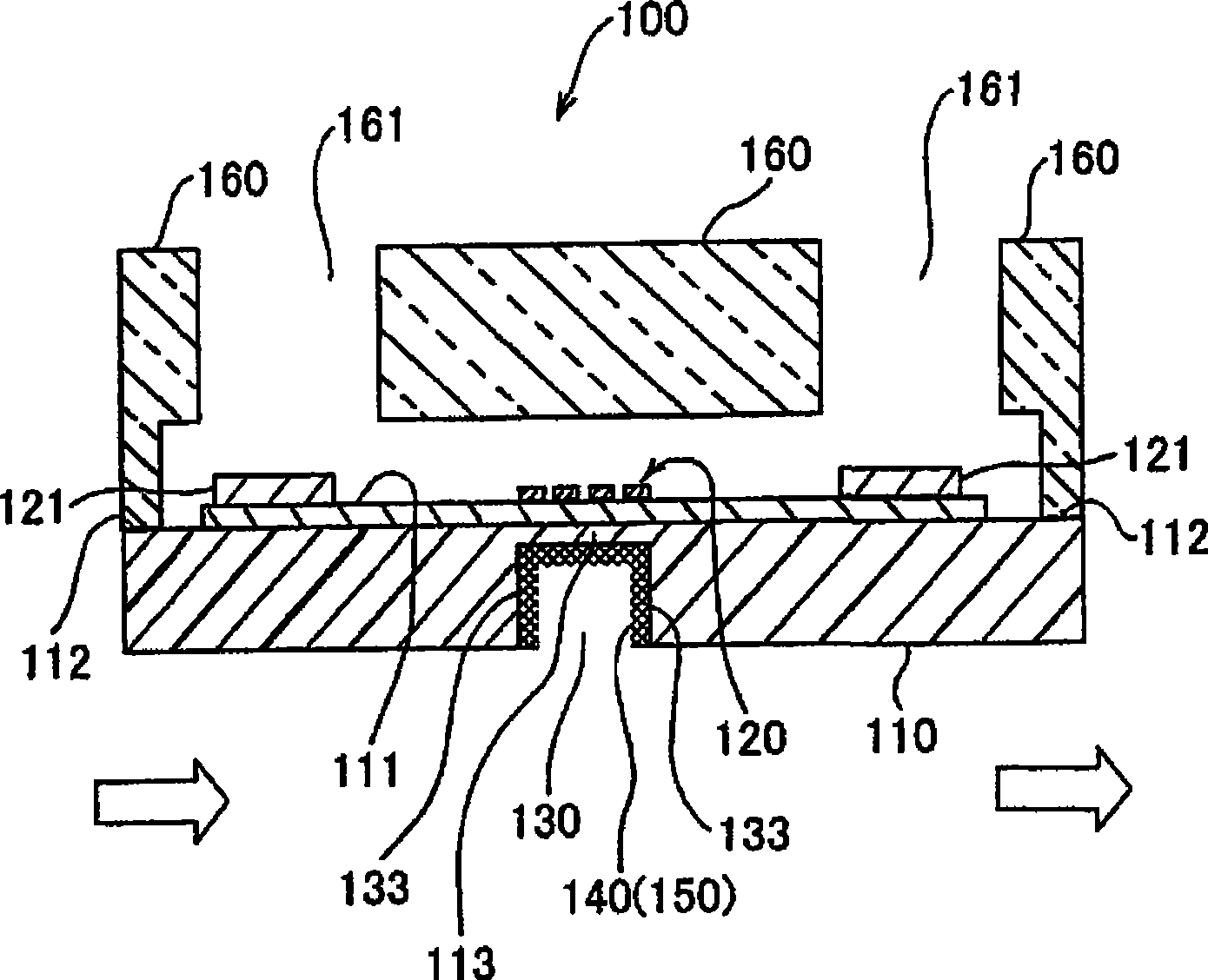

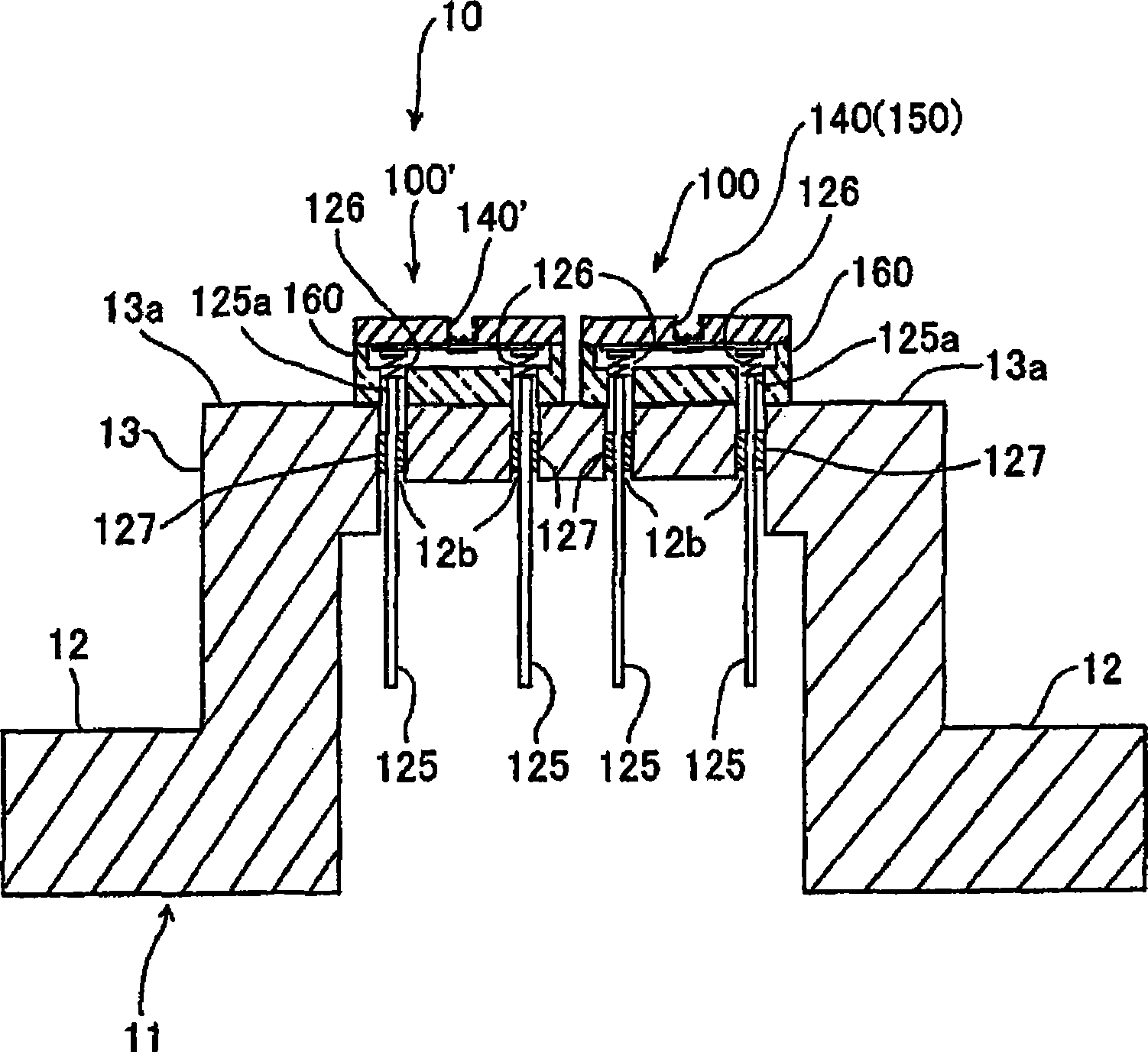

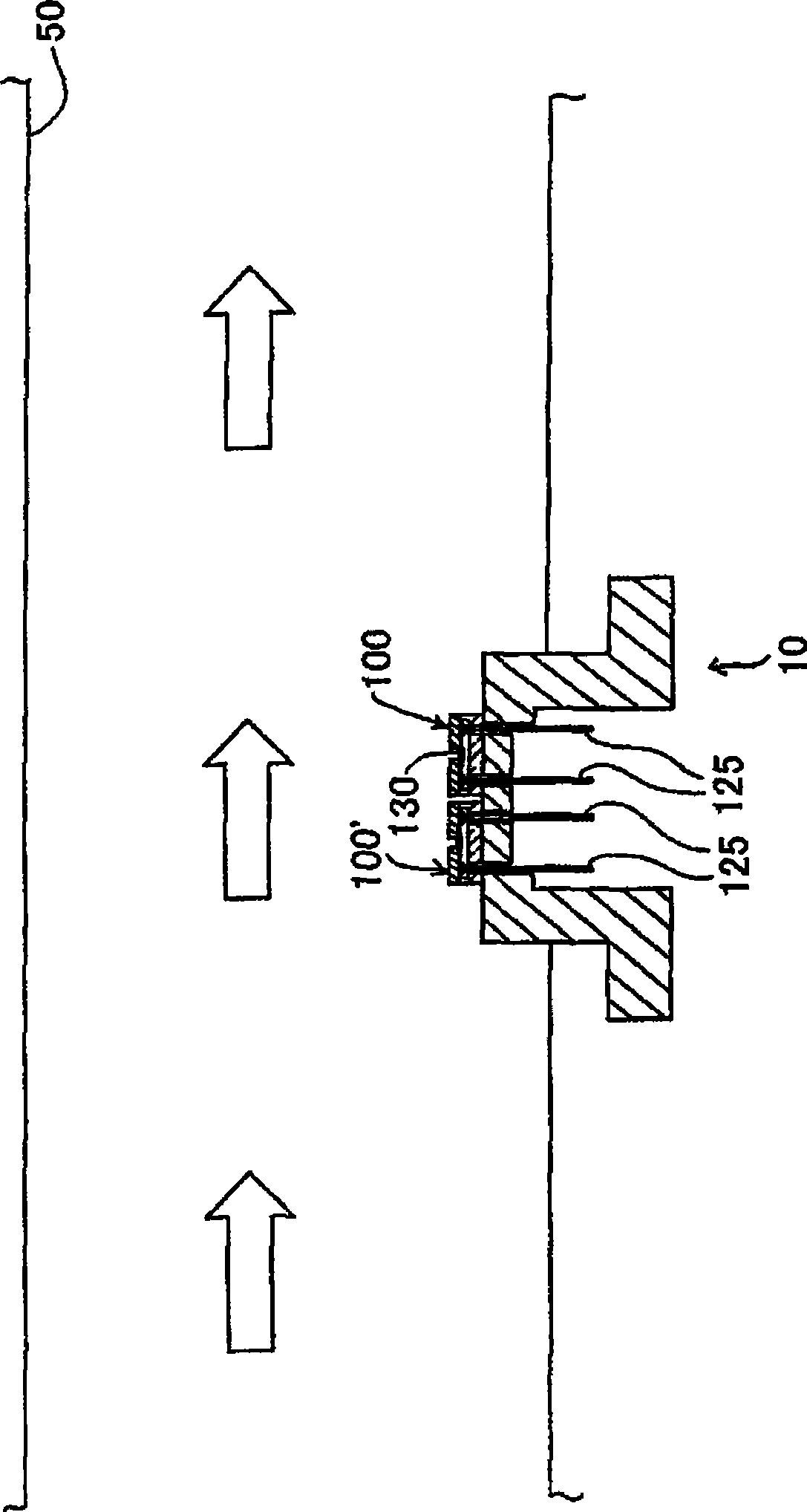

[0074] Hereinafter, the gas sensor chip 100 according to one embodiment of the present invention and the gas sensor 10 including the gas sensor chip will be described in detail with reference to the drawings. First, the gas sensor chip 100 according to one embodiment of the present invention will be described. figure 1 It is a cross-sectional view showing the gas sensor chip 100 according to one embodiment of the present invention along a direction perpendicular to the surface on which the temperature measuring resistance of the substrate 110 is formed.

[0075] Such as figure 1 As shown, the gas sensor chip 100 has: a substrate 110, a temperature-measuring resistor 120 patterned on one side of the substrate 110; a recess 130 formed on the opposite side of the substrate 110 to the temperature-measuring resistor 120; The silicon porous layer 140 on the inner surface; the oxidation combustion catalyst 150 carried by the silicon porous layer 140 ; and the glass base 160 connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com