Root defect detection method for thick-wall large-diameter pipe butt weld

A technology for butt welds and defects, applied to measuring devices, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, instruments, etc., can solve problems such as pipe wall thickness, difficulties in correct judgment and positioning, and blind spots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

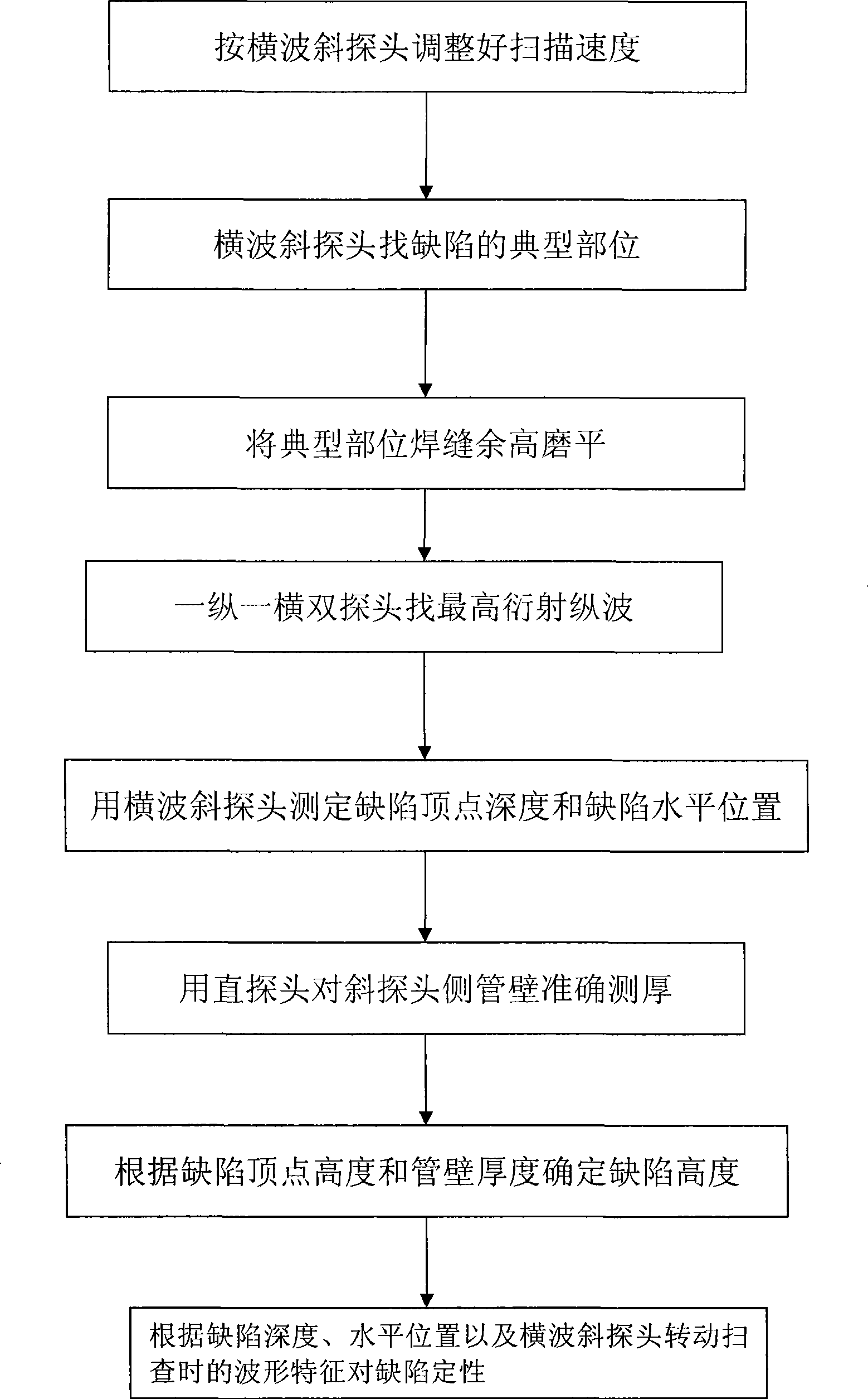

[0023] The detection method of the root defect of the thick-walled large-diameter pipe butt weld of the present invention adopts a vertical and a horizontal double-probe diffraction method, see the attached figure 1 , the detection process is:

[0024] (1) The shear wave oblique probe is used to find typical parts of root defects. Use the single shear wave oblique probe with adjusted scanning ratio to find the typical part of the weld seam with excessive signal at the root;

[0025] (2) One vertical and one horizontal dual probes to find the highest diffracted wave. Partially flatten the weld reinforcement, fix the shear wave oblique probe at the typical position of the weld, change the working mode of the flaw detector to the one-shot-one-receive mode, and set the longitudinal wave straight probe to scan the surface of the ground weld to find the highest diffraction After the wave peak, fix the position of the longitudinal wave straight probe, and scan the front and rear mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com