Electronic needle selection mechanism for jacquard machine

An electronic fountain, solenoid valve technology, applied in jacquard machines, textiles, textiles and papermaking, etc., can solve the problems of affecting the working accuracy, easy to produce jitter, damage to the solenoid valve, etc. The effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

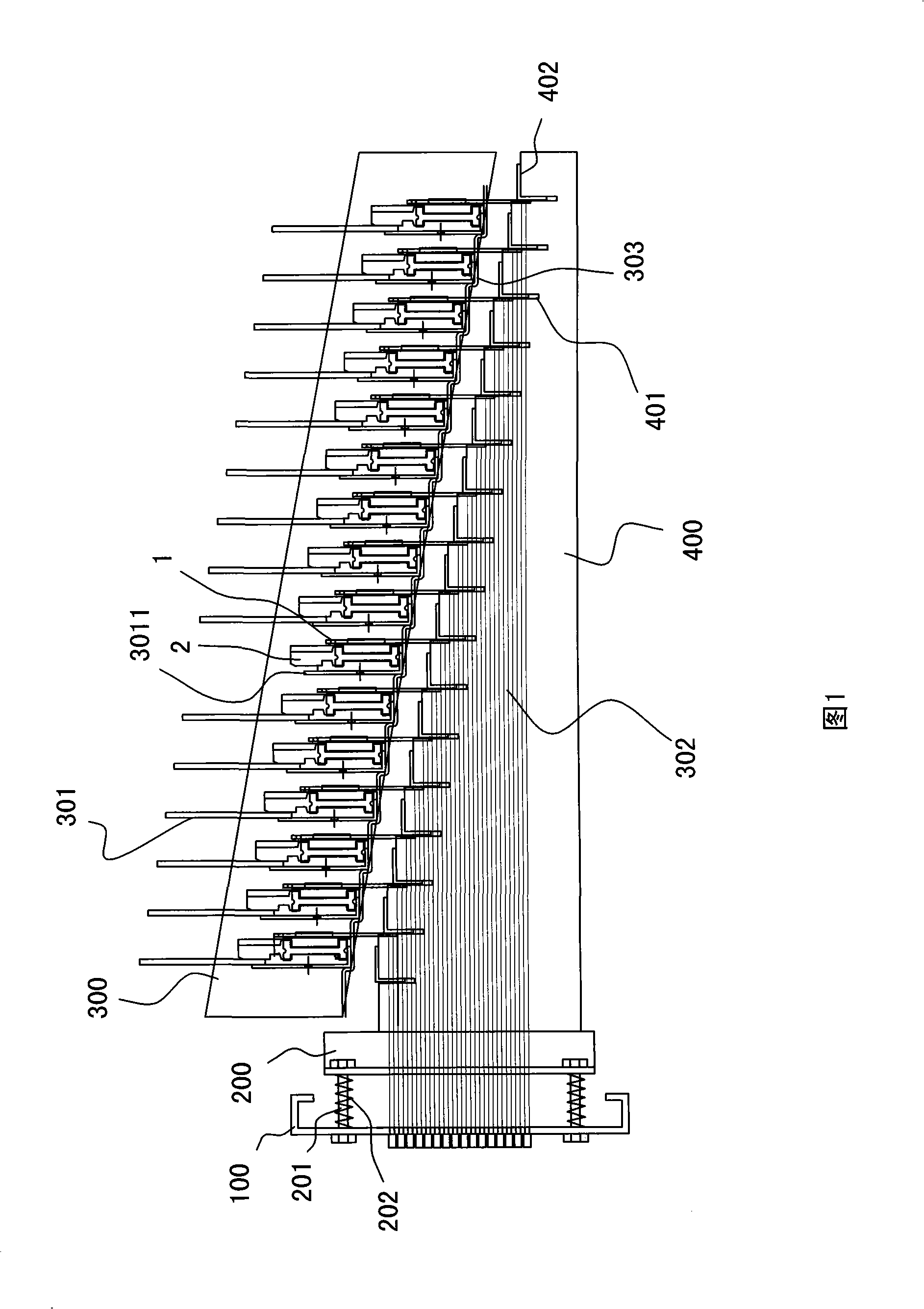

[0021] see figure 1 . From left to right, the electronic fountain includes a reset plate 100 , a push pin frame 400 and a valve seat frame 300 , the valve seat frame 300 is located above the push pin frame 400 , and the reset plate 100 is located on the left side of the push pin frame 400 . The lower ladder plate 402 of the push pin frame 400 is stepped, and the number of steps matches the number of layers of the push pins 302, and a row of push pin baffles 401 is fixedly installed on each row of steps. The push pin baffle 401 is an angle iron, one surface of the angle iron is perpendicular to the push pin 302 , and a through hole for receiving the push pin 302 is opened on it. The left side of the lower ladder plate 402 is fixedly connected to the front wall of the push pin frame 400 , and the front wall is the ejector pin frame 200 . The thimble frame 200 has a horizontal through hole for receiving the push pin 302 that is consistent with the reset plate 100. The horizonta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com