Hydraulic lifting overhead crane limit stopping mechanism

A hydraulic, stop-limited technology, applied in mechanical equipment, load suspension components, brake types, etc., can solve problems such as damage to driving-related parts, high noise, etc., to achieve the effect of not easy safety accidents, low noise, and environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

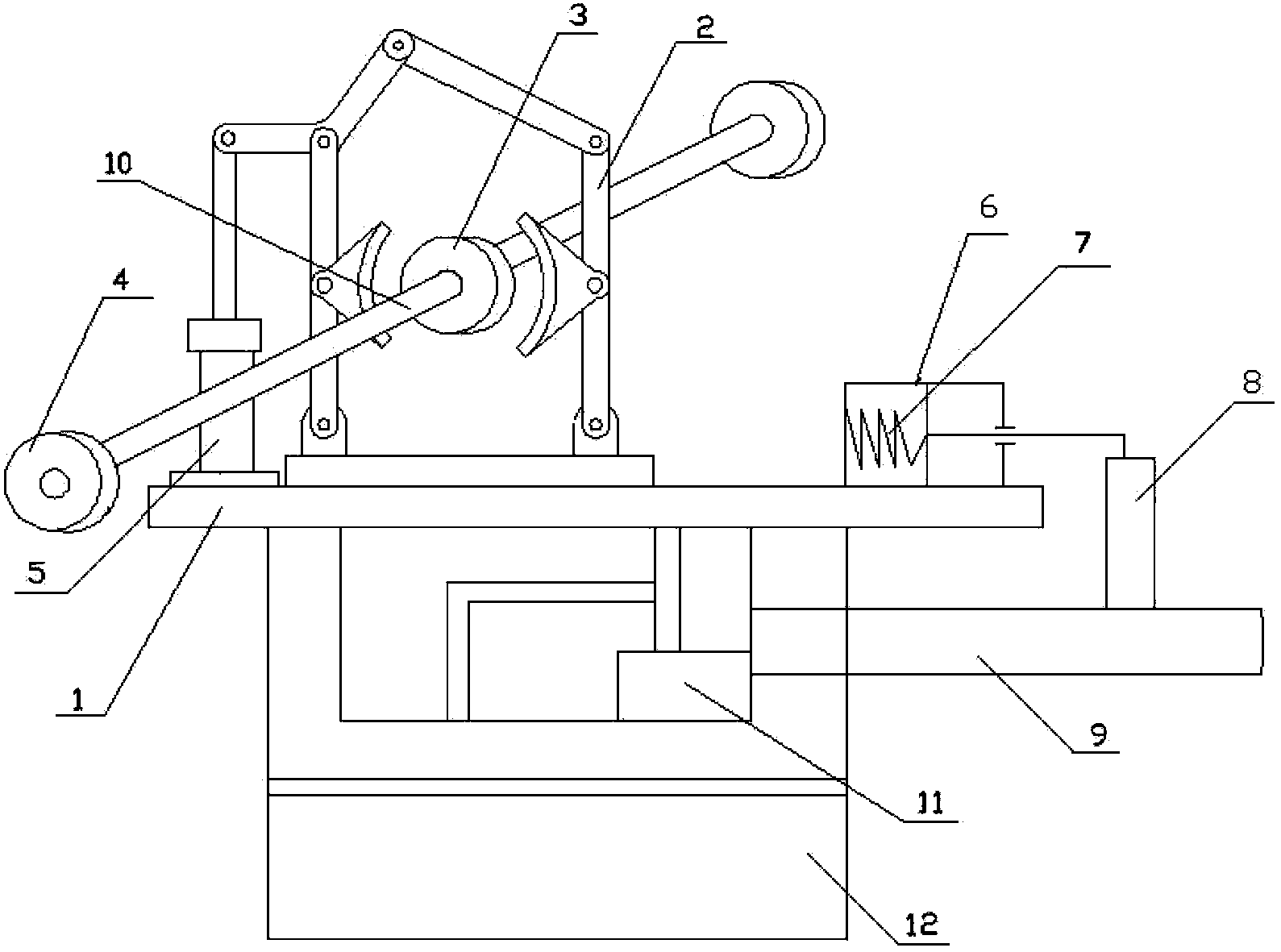

[0010] The hydraulic lifting driving stop limit mechanism has a row of car bodies (1), on which a hydraulic brake mechanism (2) is installed, and a traveling car is installed on the hydraulic brake mechanism (2). Axle (10), brake wheel (3) and travel wheel (4); On the side of the traveling body (1), a buffer hydraulic cylinder (6) is installed, and a buffer hydraulic cylinder (6) is installed in the inner cavity of the buffer hydraulic cylinder (6). Compress the spring (7), and connect the buffer hydraulic cylinder (6) to the brake hydraulic cylinder (5) installed on the hydraulic brake mechanism (2) through the oil pipe; one end of the compression spring (7) is connected to a limit stop plate (8), install the limit stop plate (8) on the top of the guide rail (9), connect a starting mechanism (11) on the guide rail (9), install the starting mechanism (11) on the starting gearbox (12) in the lumen.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com