Bearing device for wheel

A technology for bearing devices and wheels, which is applied to bearings, bearing components, roller bearings, etc., and can solve problems such as not being able to obtain optimal stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0117] Preferred embodiments of the present invention will be described below with reference to the accompanying drawings.

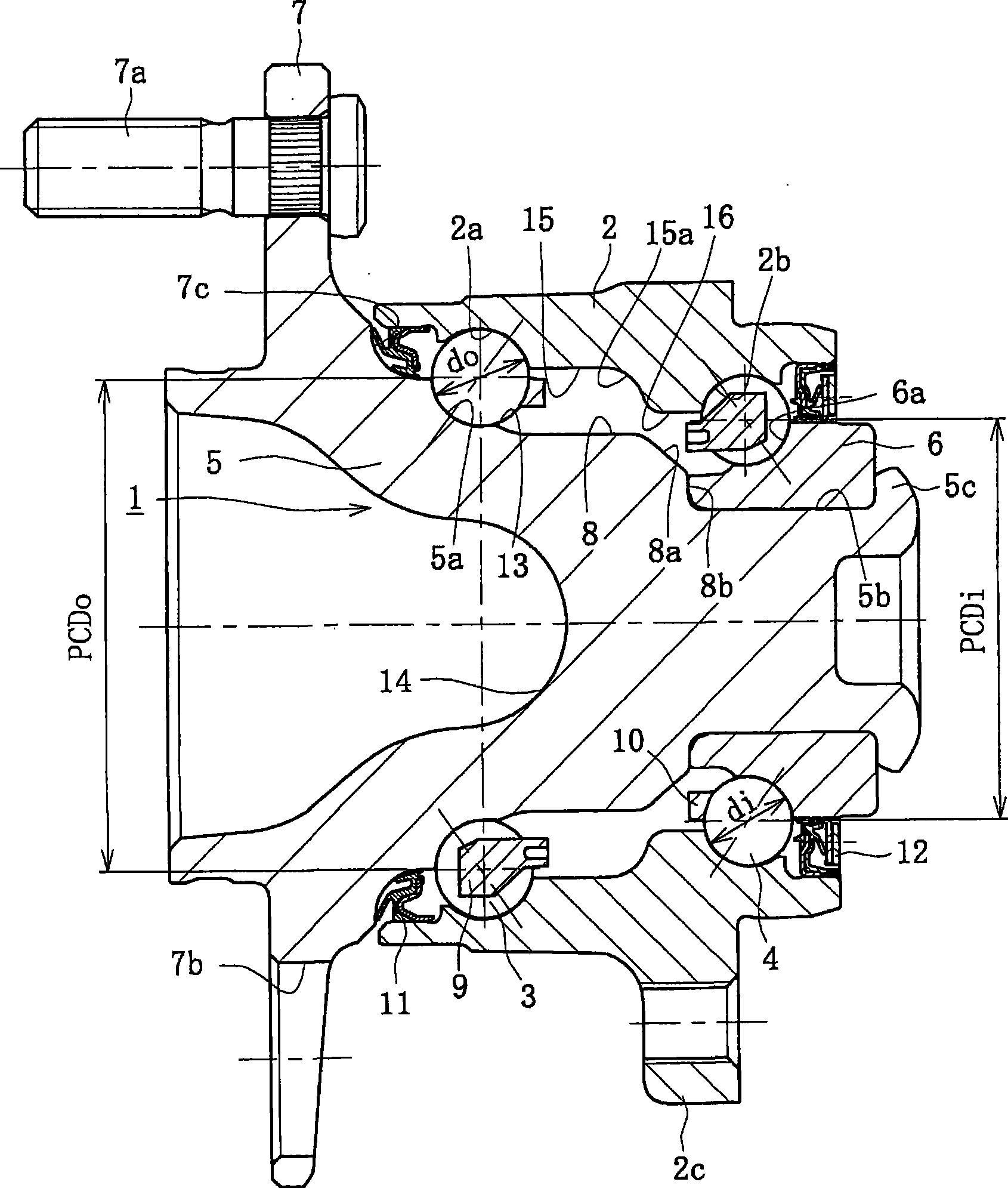

[0118] figure 1 It is a longitudinal sectional view showing the first embodiment of the wheel bearing device of the present invention.

[0119] figure 1 The wheel bearing device of the present invention shown is of the third generation type for driven wheels and comprises an inner part 1, an outer part 2 and a double row ball set rotatably accommodated between the inner part 1 and the outer part 2 3, 4. The inner part 1 includes a wheel hub 5 and an inner ring 6 press-fitted on the wheel hub 5 with a predetermined interference.

[0120] The wheel hub 5 is integrally formed with a wheel mounting flange 7 at one end thereof, an (outer) inner raceway surface 5a having a circular arc-shaped cross-section on its outer periphery, and a shaft-like portion 8 extending from the inner raceway surface 5a. The cylindrical part 5b. A plurality of hub bolts 7a ...

no. 2 approach

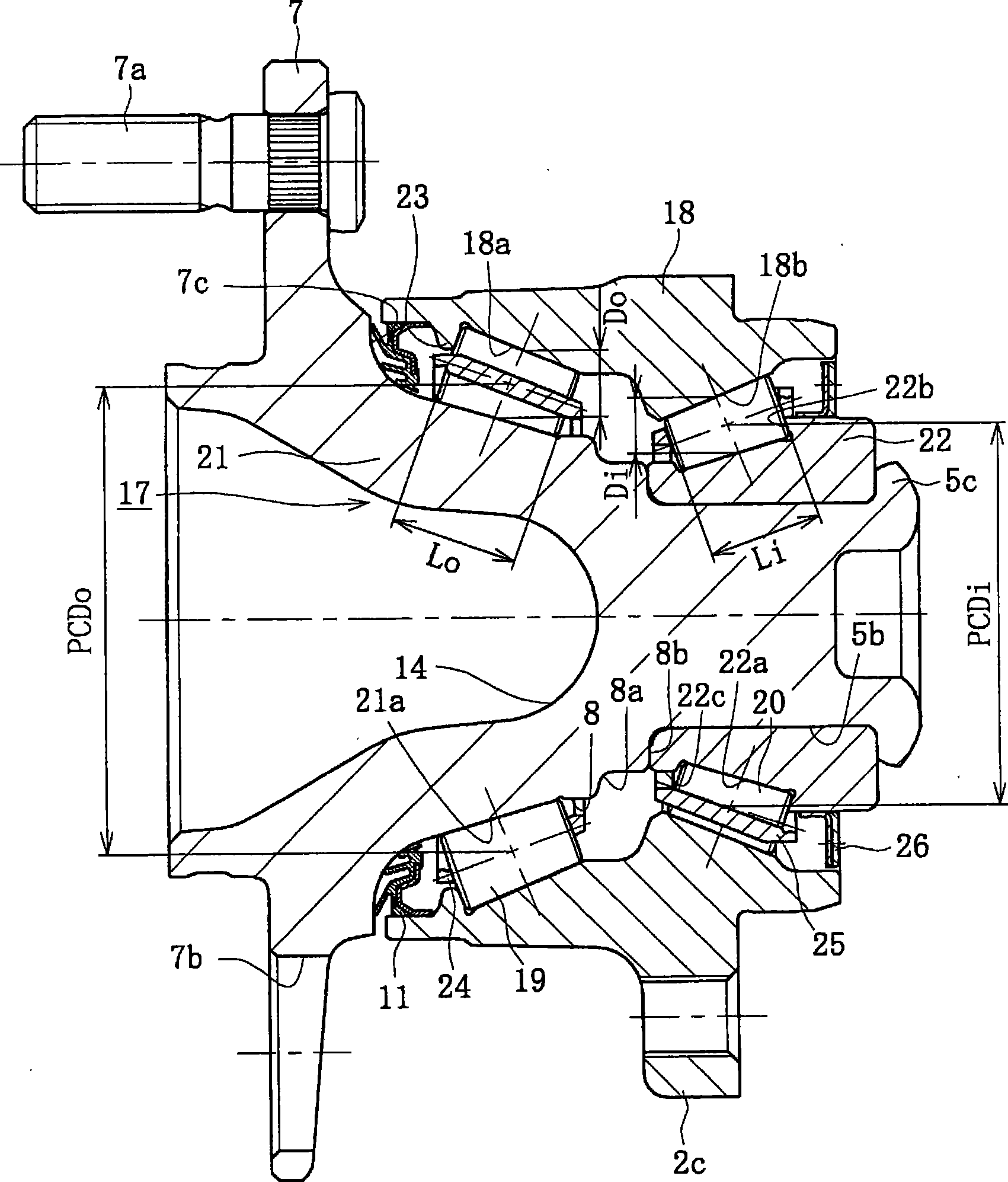

[0130] figure 2 It is a longitudinal sectional view showing a second embodiment of the wheel bearing device of the present invention. The same reference numerals are used here to denote the same components having the same functions as those used in the first embodiment.

[0131] figure 2The wheel bearing device of the present invention shown is of the third generation type for driven wheels and comprises an inner part 17, an outer part 18 and a double row cone which is accommodated freely rolling between the inner part 17 and the outer part 18. Shape roller 19,20. The inner member 17 includes a wheel hub 21 and an inner ring 22 press-fitted on the wheel hub 21 with a predetermined interference.

[0132] The wheel hub 21 is integrally formed with a wheel mounting flange 7 at one end thereof, a (outer) tapered inner raceway surface 21a on its outer periphery, and a shaft extending from the inner raceway surface 21a through an axially extending shaft-like portion 8. Cylindr...

no. 3 approach

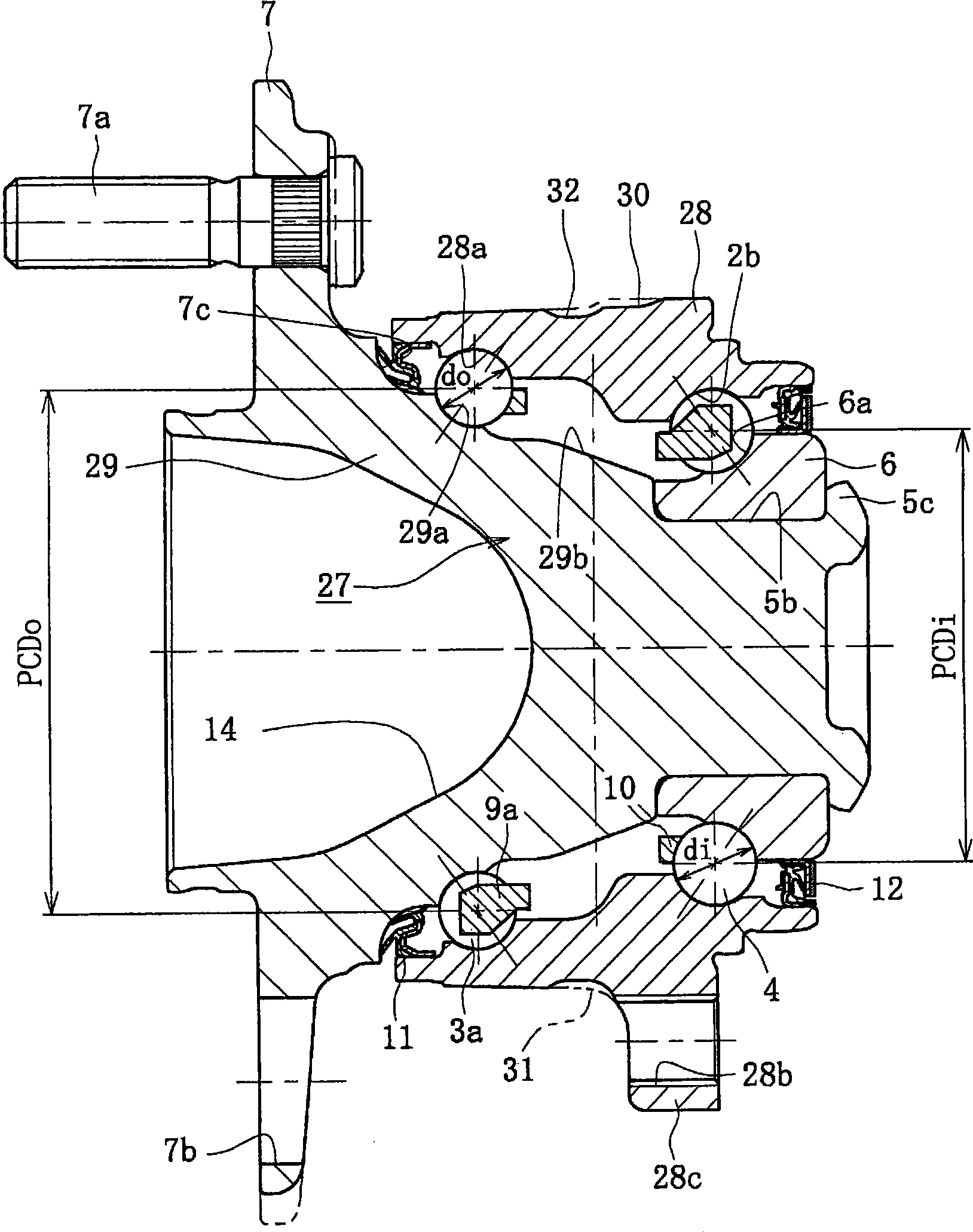

[0140] image 3 is a longitudinal sectional view showing a third embodiment of the wheel bearing device of the present invention, Figure 4 yes image 3 side view, Figure 5 yes image 3 A partial enlargement of the . The same reference numerals are used here to denote the same components having the same functions as those used in the previous embodiments.

[0141] image 3 The wheel bearing device of the present invention shown is of the third generation type for driven wheels and comprises an inner part 27, an outer part 28 and a double row of balls housed freely rolling between the inner part 27 and the outer part 28 Group 3a, 4. The inner member 27 includes a wheel hub 29 and the inner ring 6 press-fitted on the wheel hub 29 with a predetermined interference.

[0142] The wheel hub 29 is integrally formed with the wheel mounting flange 7 at its outer end, an (outer) inner race surface 29a on the outer periphery, and a cylindrical portion extending from the inner rac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com