Method for paving channel steel cover plate

A laying method and technology of steel cover plate, applied in the direction of waterway system, water conservancy project, artificial island, etc., can solve the problems of poor appearance, affecting the smoothness of concrete pouring, difficulty in leveling, etc., achieve good economic and technical effects, and reduce secondary repairs , Look and feel and good quality effect

Active Publication Date: 2010-08-18

MCC TIANGONG GROUP

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Although this construction method can achieve the purpose of installing the steel cover plate, there are still the following problems: 1. Due to the long construction channel, when pouring concrete, flashes and burrs are prone to appear on the concrete surface in contact with the wood plaster, resulting in the steel cover plate being in the It is very difficult to straighten during installation; 2. When the concrete surface is leveled, it is difficult to fix the wooden formwork, which directly affects the leveling of concrete pouring; 3. When the steel cover is laid, it is difficult to level the part that is in contact with the concrete, and the appearance is very poor; 4. .This construction method requires secondary repairs in most cases, which is time-consuming and affects the overall quality of construction

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

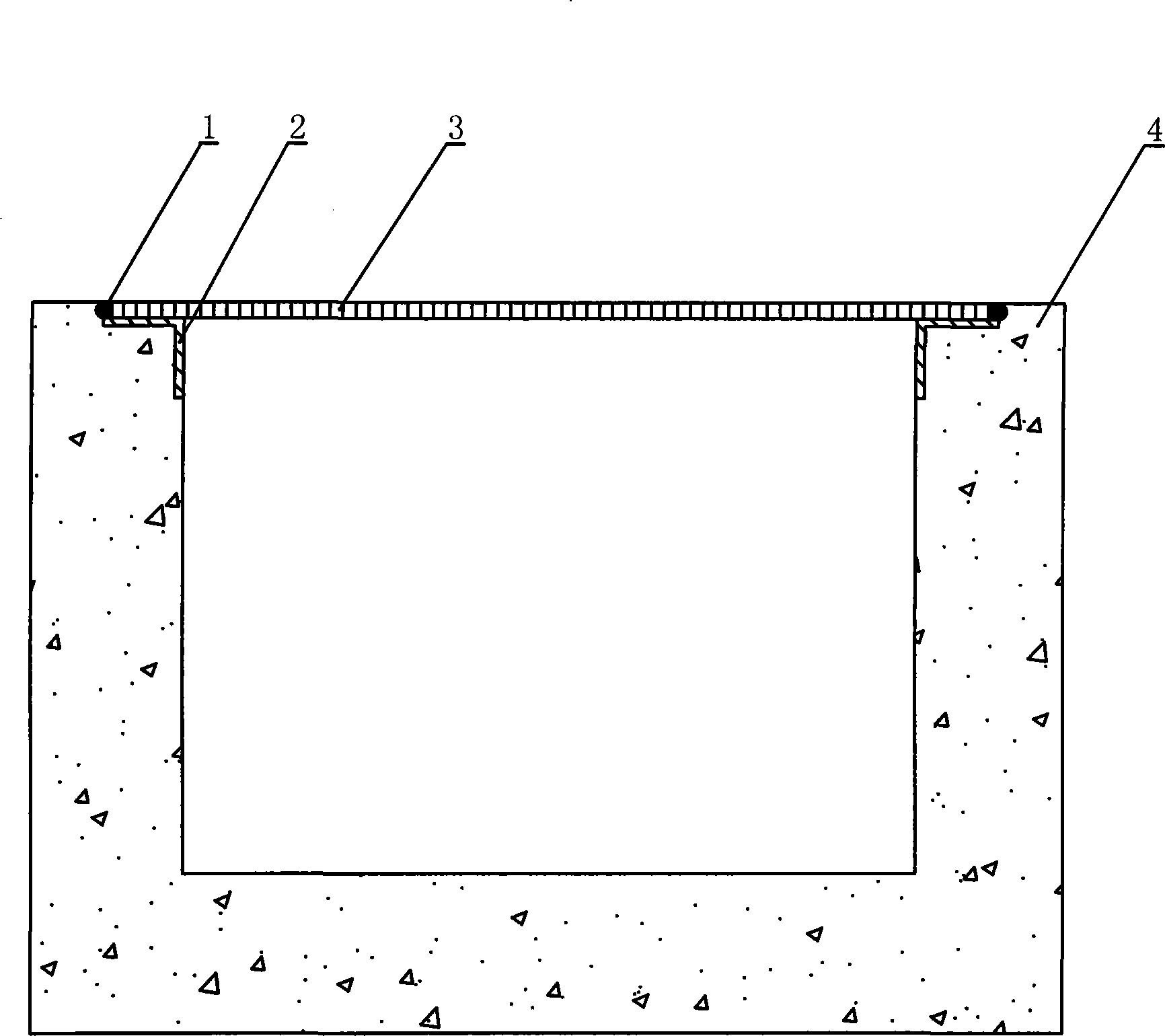

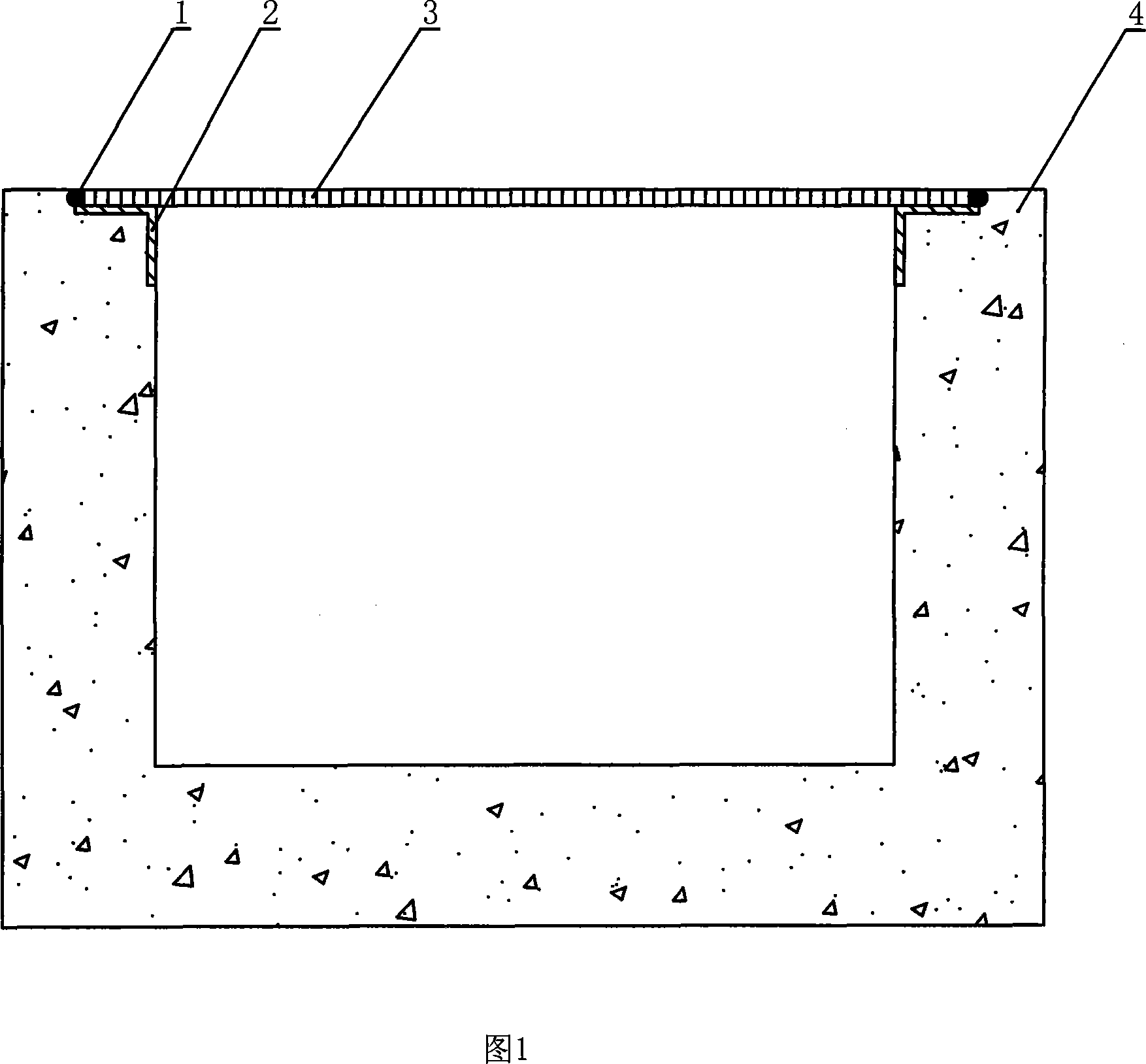

The invention relates to a method for paving a channel steel cover plate, which comprises the following steps: (1) pre-embedding an edge-protecting angle steel at end corners on two sides of foundation concrete of a channel respectively; (2) fixedly mounting round steels on the foundation concrete on the outsides of flanges of the edge-protecting angle steels on two sides of the channel symmetrically at full length, and aligning the round steels; and (3) paving the steel cover plate on the edge-protecting angle steels between the round steels on the two sides of the channel to finish the paving. The paving method has the advantages of simplicity, scientific and reasonable design, and better impression and quality, and is a laborsaving and timesaving method for paving the channel steel cover plate.

Description

technical field The invention relates to the field of construction, in particular to a method for laying a channel steel cover plate. Background technique In the foundation construction of modern industrial equipment, it is often necessary to excavate various trenches, such as cable trenches, hydraulic trenches, pipe trenches, etc. Generally, the trench design is below ±0.0m, and its cross-section is "U"-shaped, with a steel cover laid on the top Plate, the steel cover plate usually adopts patterned steel plate with t=6mm or t=8mm (the steel plate with larger thickness can be selected when the load on the steel cover plate is large), and the steel cover plate should be level with the foundation concrete surface or ground after laying. At present, the laying method of the steel cover plate of the channel generally adopts the pre-embedded edge protection angle steel at the corner of the channel. The elevation of the top plane of the angle steel is lower than the concrete surfa...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): E02D29/09E02D29/14E03F5/00

Inventor 张晓平高美忠张鹏飞

Owner MCC TIANGONG GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com