Lunar rover release mechanism of vertical elevating type

A release mechanism and vertical lifting technology, which is applied in the aerospace field, can solve the problems of easy deformation of the slideway processing accuracy, low release height, and large power consumption, and achieve the effects of simple structure, high release height, and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

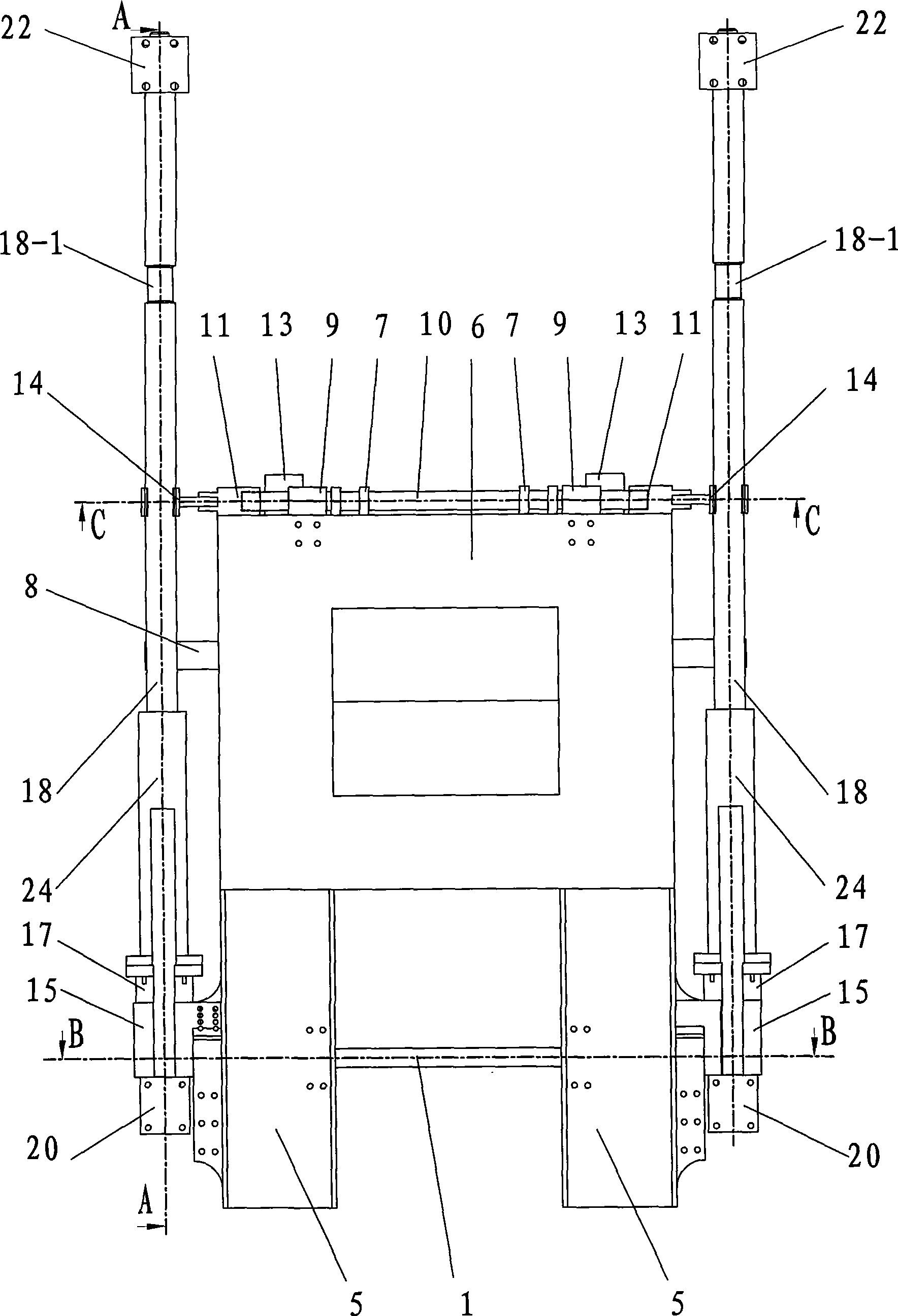

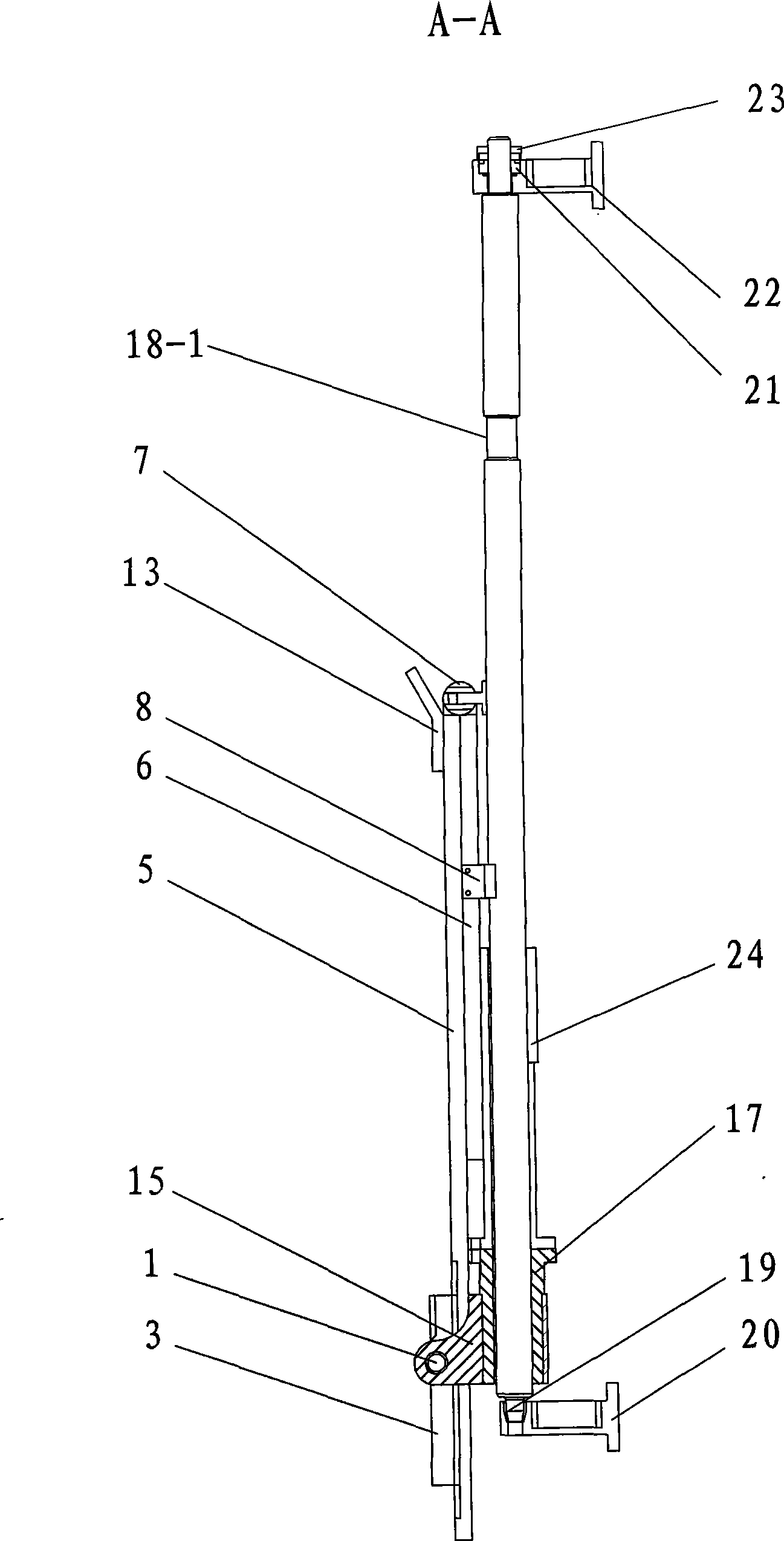

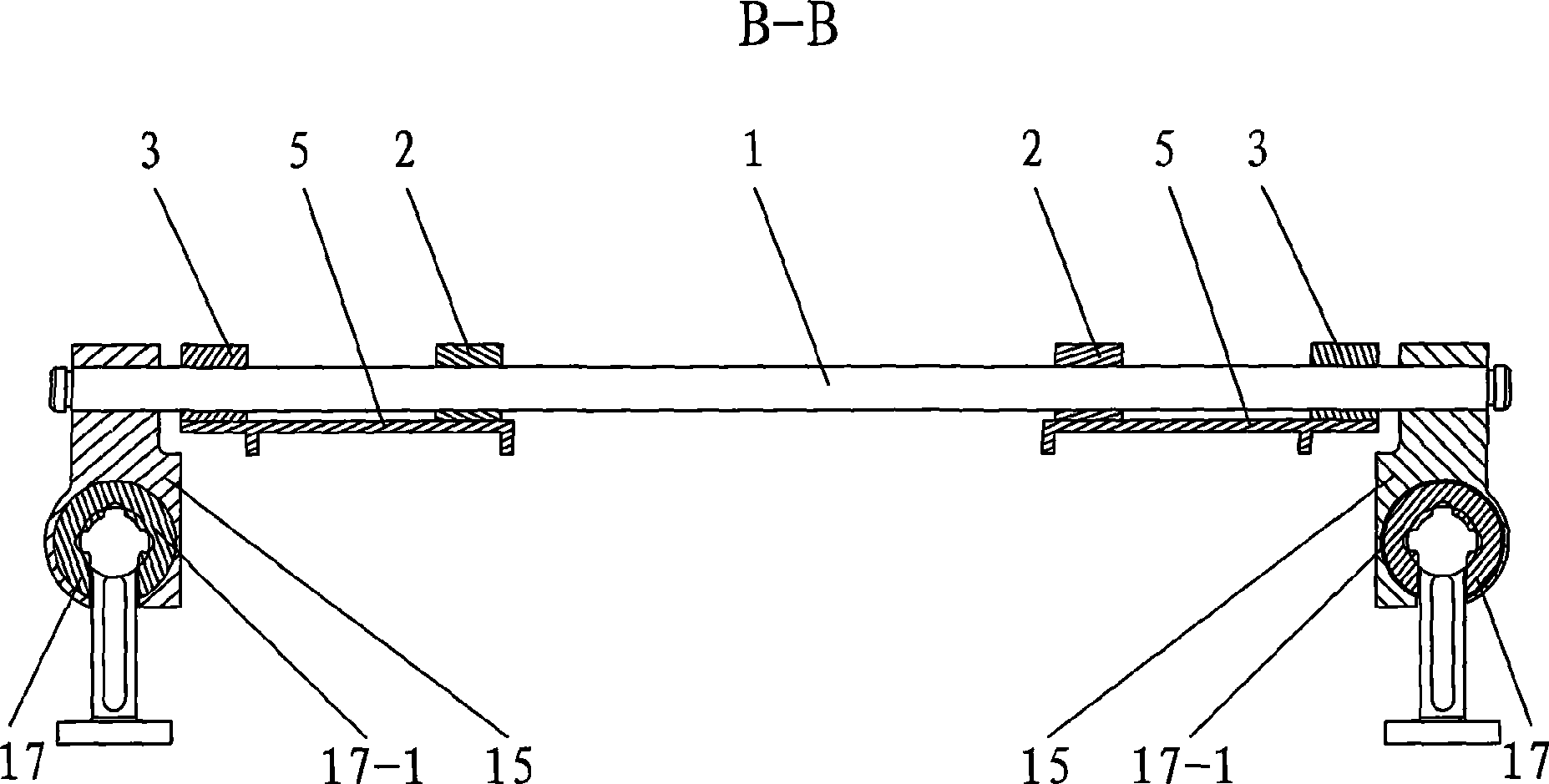

[0008] Specific implementation mode one: combine Figure 1 ~ Figure 4 Describe this embodiment, the vertical lift type lunar rover release mechanism of this embodiment is composed of a screw drive part, a casing part, a display board and a locking and unlocking part, and the screw drive part is fixed by two lead screws 18 and two bearings Nut 23, two bearings 21, two upper bearing seats 22, two bearing bushes 19 and two lower bearing seats 20 are formed, and described two leading screws 18 are arranged vertically in parallel, and the top of each leading screw 18 is all opened with Light groove 18-1, the upper end of each leading screw 18 is all installed on the upper bearing seat 22 through bearing 21 and bearing fixing nut 23, and the lower end of each leading screw 18 is all installed on the lower bearing seat 20 through bearing bush 19; The casing part is composed of two upper casings 24, two middle casings 17, two lower casings 15 and the rear axle 1, and the lower part of...

specific Embodiment approach 2

[0009] Specific implementation mode two: combination image 3 To describe this embodiment, the middle casing 17 of this embodiment is provided with a plurality of dust-proof grooves 17-1. With such a setting, it is realized that there is no jamming in the case of dust, and it still works normally. Other components and connections are the same as those in the first embodiment.

[0010] Working principle of the present invention: (see Figure 1 to Figure 7 ) initial position, the long plate 5 and the short plate 6 are in the folded state, the short plate 6 is located on the inner side of the long plate 5, and the unlocking button 14 is buckled on the lead screw 18 to realize the locking function; the lead screw 18 drives the casing part to move upward, The display board and the locking and unlocking part will also move upwards along the leading screw 18. At the light groove 18-1 of the leading screw 18, by the action of the torsion spring 7 mounted on the rear axle 1, the unlo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com