Device for testing constant thrust load of continuous linear motor

A linear motor and load testing technology, applied to measuring devices, force/torque/power measuring instruments, instruments, etc., can solve the problems of complex measurement process, poor precision, one-way measurement, etc., and achieve simple structure of the device, reduce errors, Effects that are cheap to manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

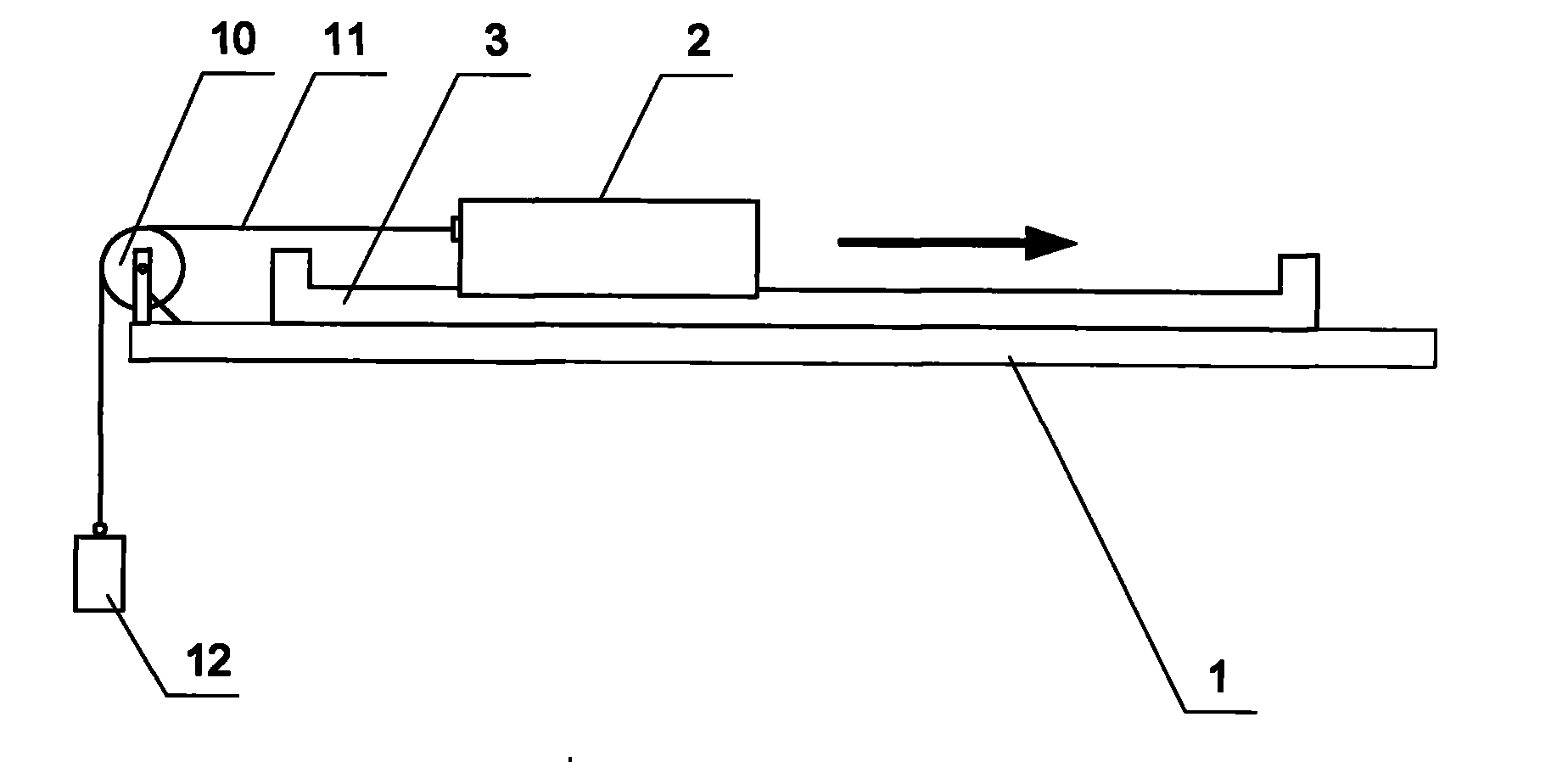

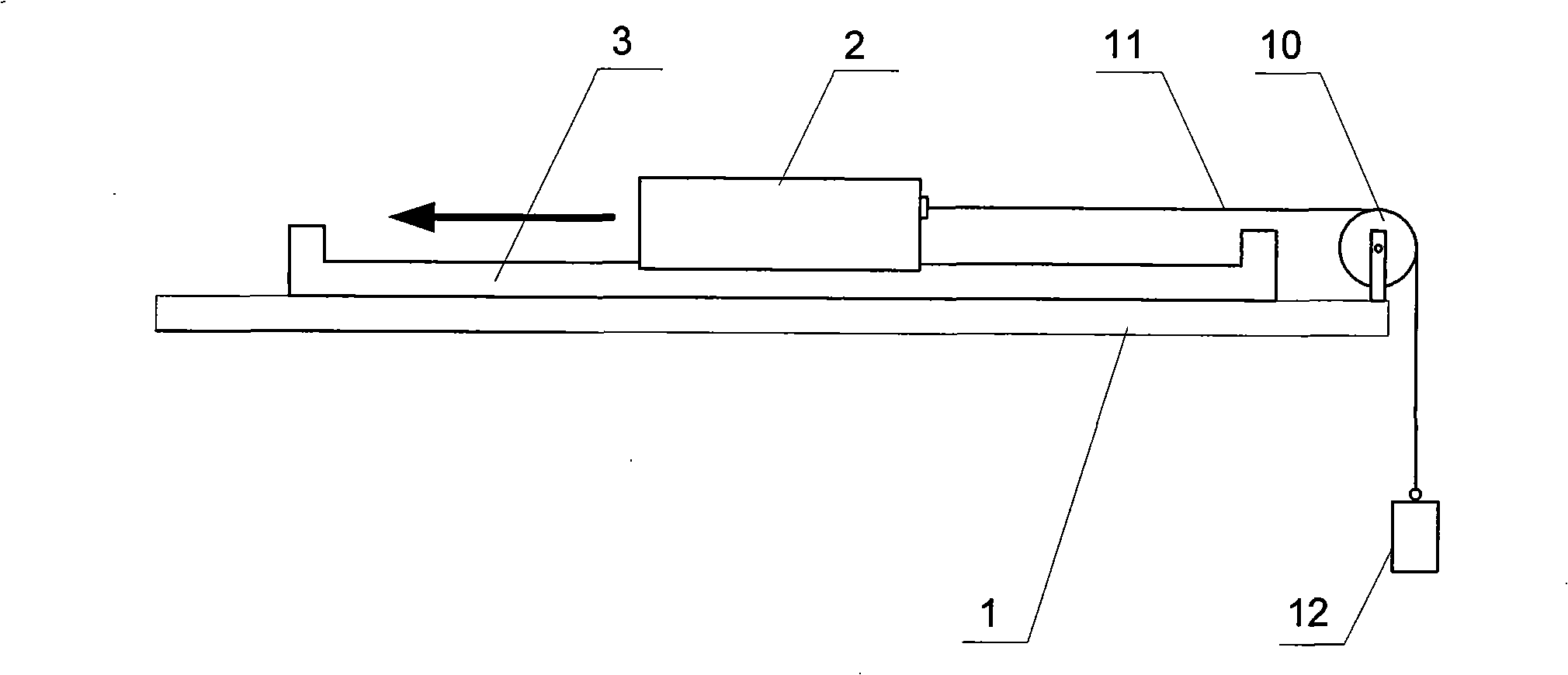

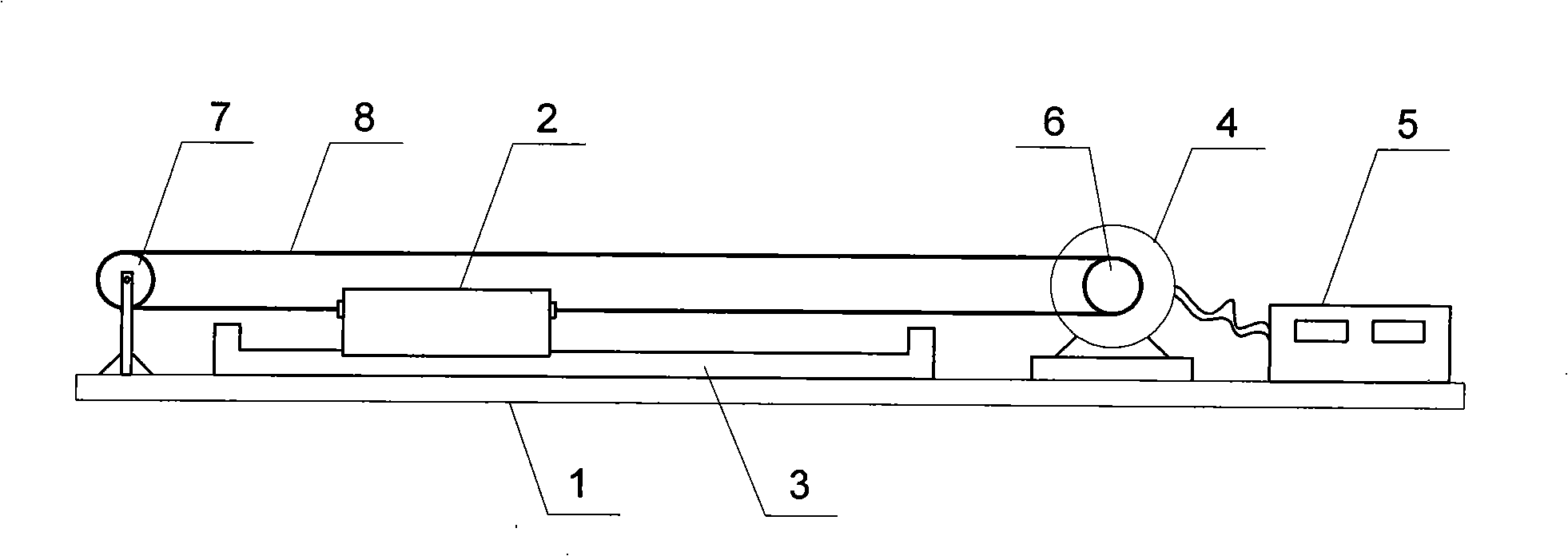

[0010] Specific implementation mode 1: the following combination image 3 To explain this embodiment, this embodiment includes a test platform 1, a linear motor, a magnetic powder brake 4, a DC power supply 5, a first synchronous wheel 6, a second synchronous wheel 7 and a synchronous belt 8. The linear motor includes the mover 2 of the linear motor and The stator 3 of the linear motor is set on the test platform 1. The linear motor is located between the first synchronous wheel 6 and the second synchronous wheel 7. One end of the test platform 1 is provided with a magnetic powder brake 4, and the output shaft of the magnetic powder brake 4 is connected with The first synchronous wheel 6 is fixedly connected. The two ends of the synchronous belt 8 are respectively connected to the two ends of the linear motor mover 2. The linear motor mover 2 drives the first synchronous wheel 6 and the second synchronous wheel 7 to rotate through the synchronous belt 8 , The DC power supply 5 p...

specific Embodiment approach 2

[0011] Second embodiment: The difference between this embodiment and the first embodiment is that the diameter of the first synchronizing wheel 6 and the second synchronizing wheel 7 are the same, and the other components and connection modes are the same as those of the first embodiment.

specific Embodiment approach 3

[0012] Specific embodiment 3: The difference between this embodiment and the first embodiment is that the linear motor selects a flat linear motor, a cylindrical linear motor or a double-sided linear motor, and other components and connection modes are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com