A system and a method for detecting gas turbine blade or aircraft engine blade problems in real time

A technology of aircraft engines and gas turbines, which is applied in the direction of gas turbine engine testing, machine/engine, engine testing, etc., and can solve problems such as damage, unplanned maintenance, and loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

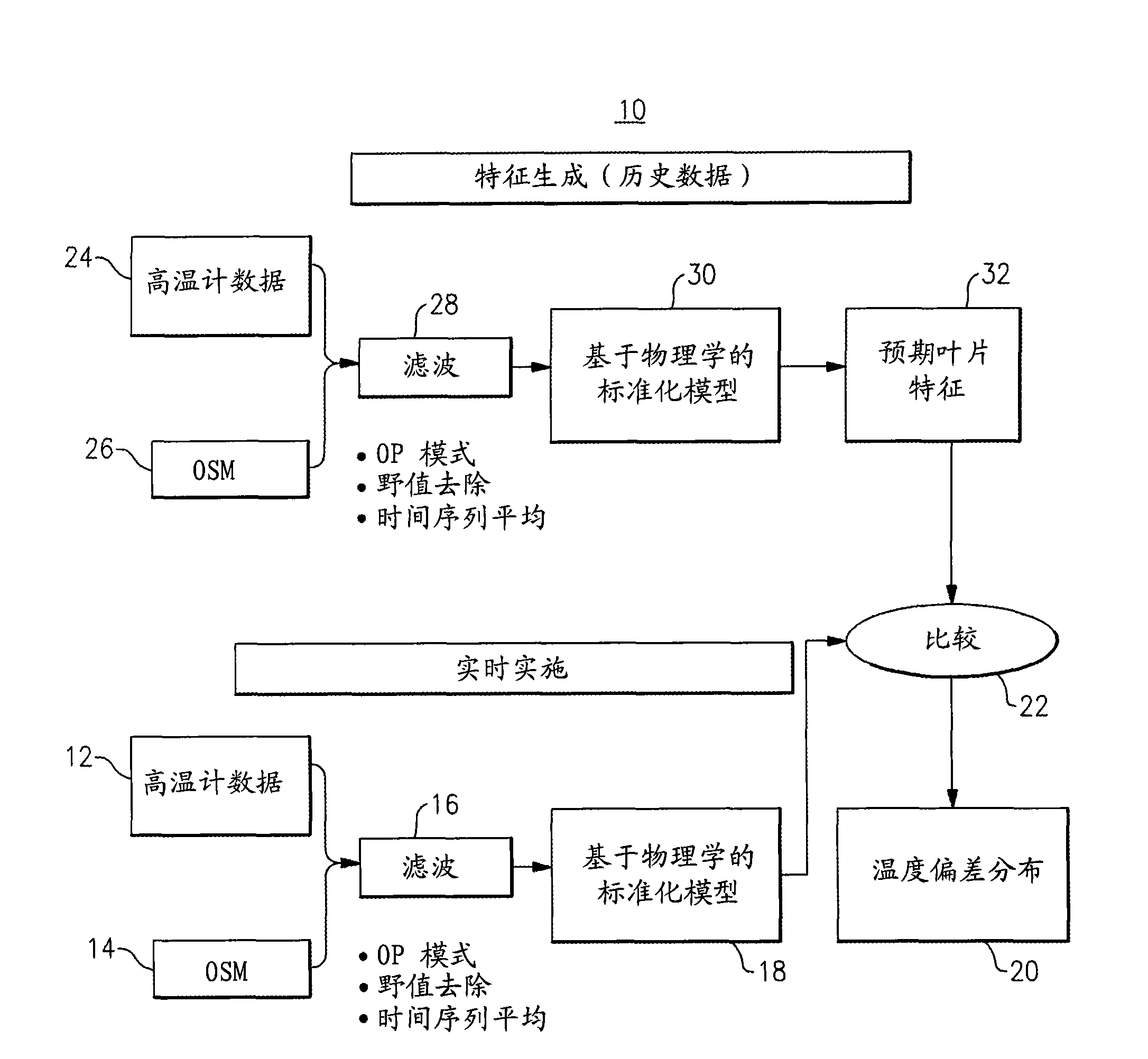

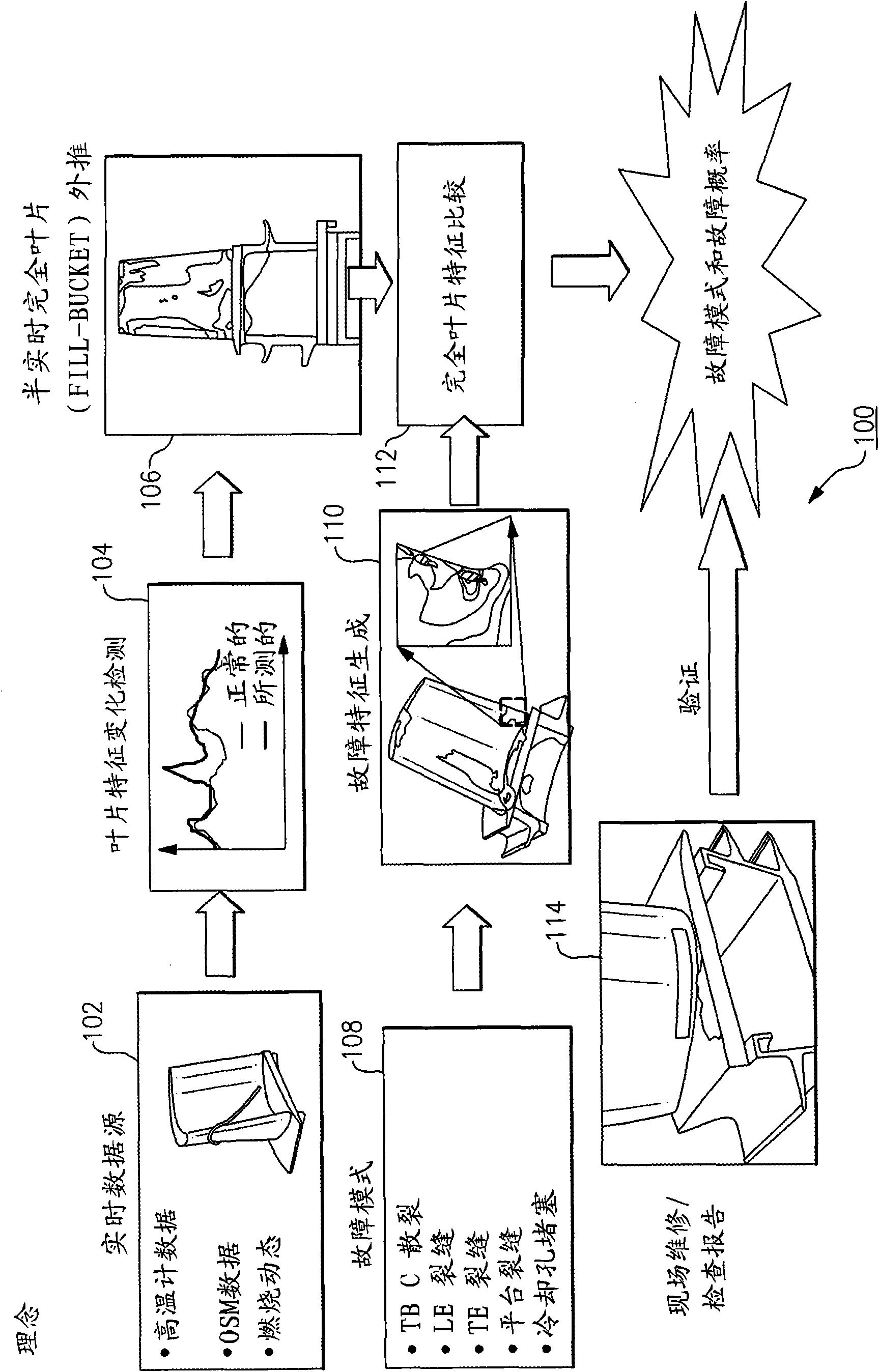

[0016] figure 1 Is a flowchart of a method and system 10 for real-time detection of gas turbine or aircraft engine blade problems according to one embodiment. System 10 may provide a means for real-time detection of gas turbine or aircraft engine blade problems, including, but not limited to, gas turbine or aircraft engine blade failure, when the turbine or aircraft engine is operating using gas turbine or aircraft engine operating data and optical pyrometer data. Thermal barrier coating spalls, cracks, and blocked cooling channels.

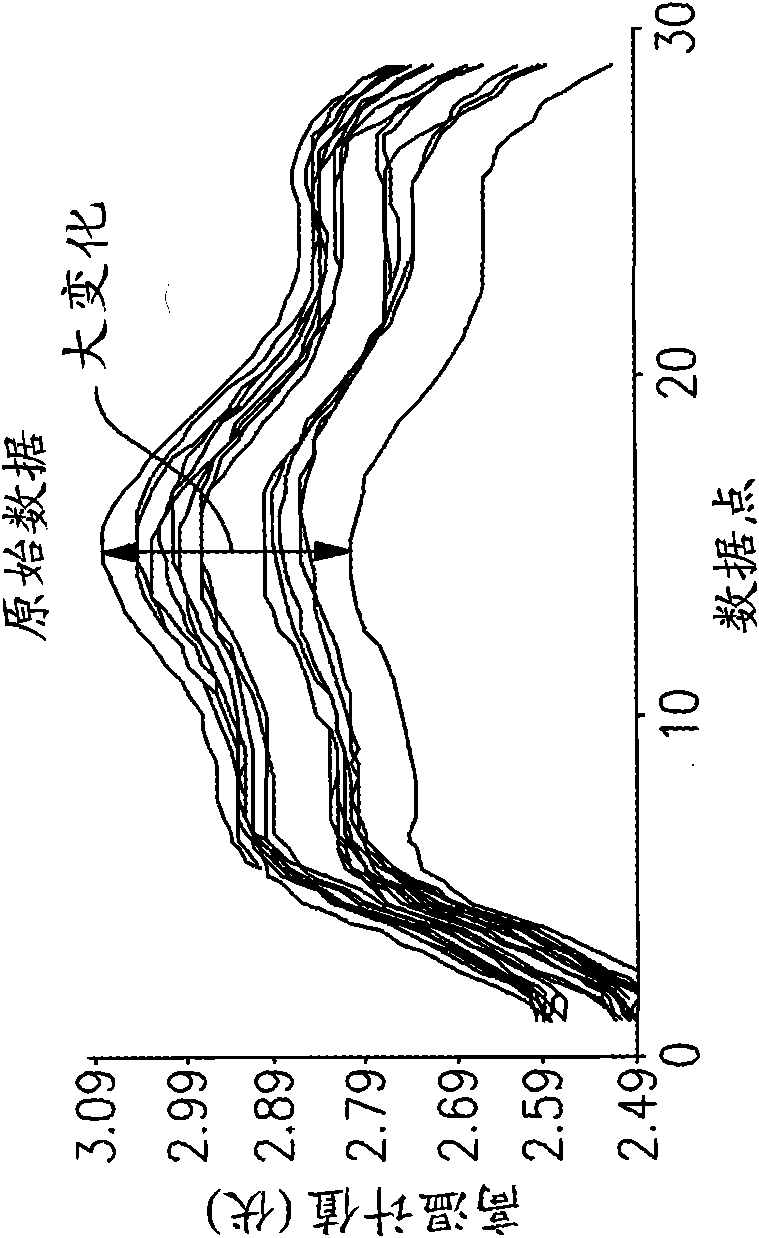

[0017] According to one aspect, system 10 utilizes at least one optical pyrometer 12 to generate optical pyrometer data. However, it is difficult to develop a monitoring system based on optical pyrometer data since the absolute temperature value of the blade needs to be known. For example, it is difficult to base the signal acquired by the optical pyrometer 12 with respect to absolute temperature due to emissivity variations and / or blockages wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com