Print job control apparatus and print job control method

一种印刷作业、控制设备的技术,应用在数字输出到打印单元、永久直观显示的装置、仪器等方向,能够解决操作者不能够容易地进行改变等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Hereinafter, embodiments for carrying out the present invention will be described in detail while referring to the accompanying drawings. It should be noted that the same reference numerals are assigned to the same structural elements, and descriptions thereof will be omitted.

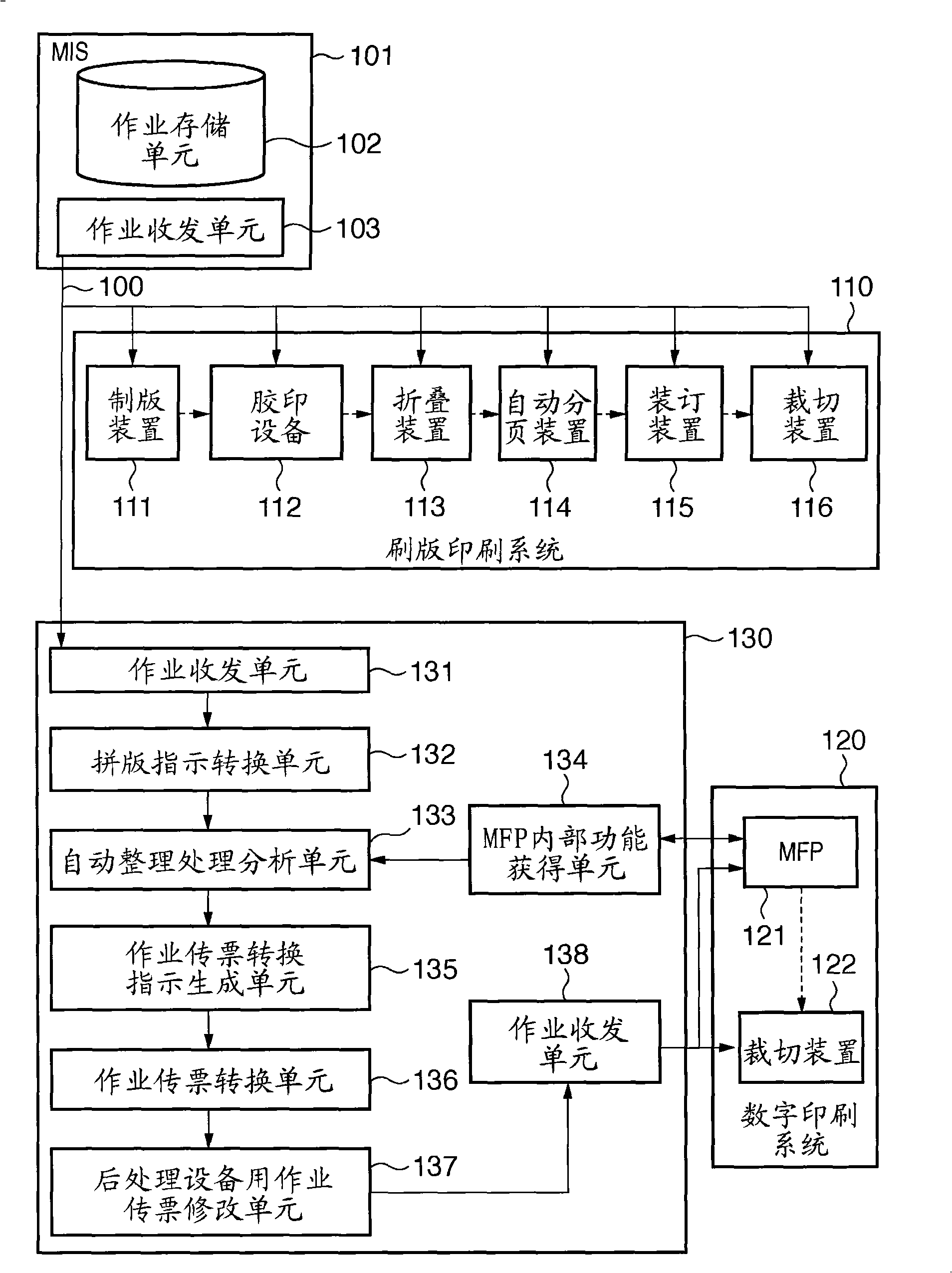

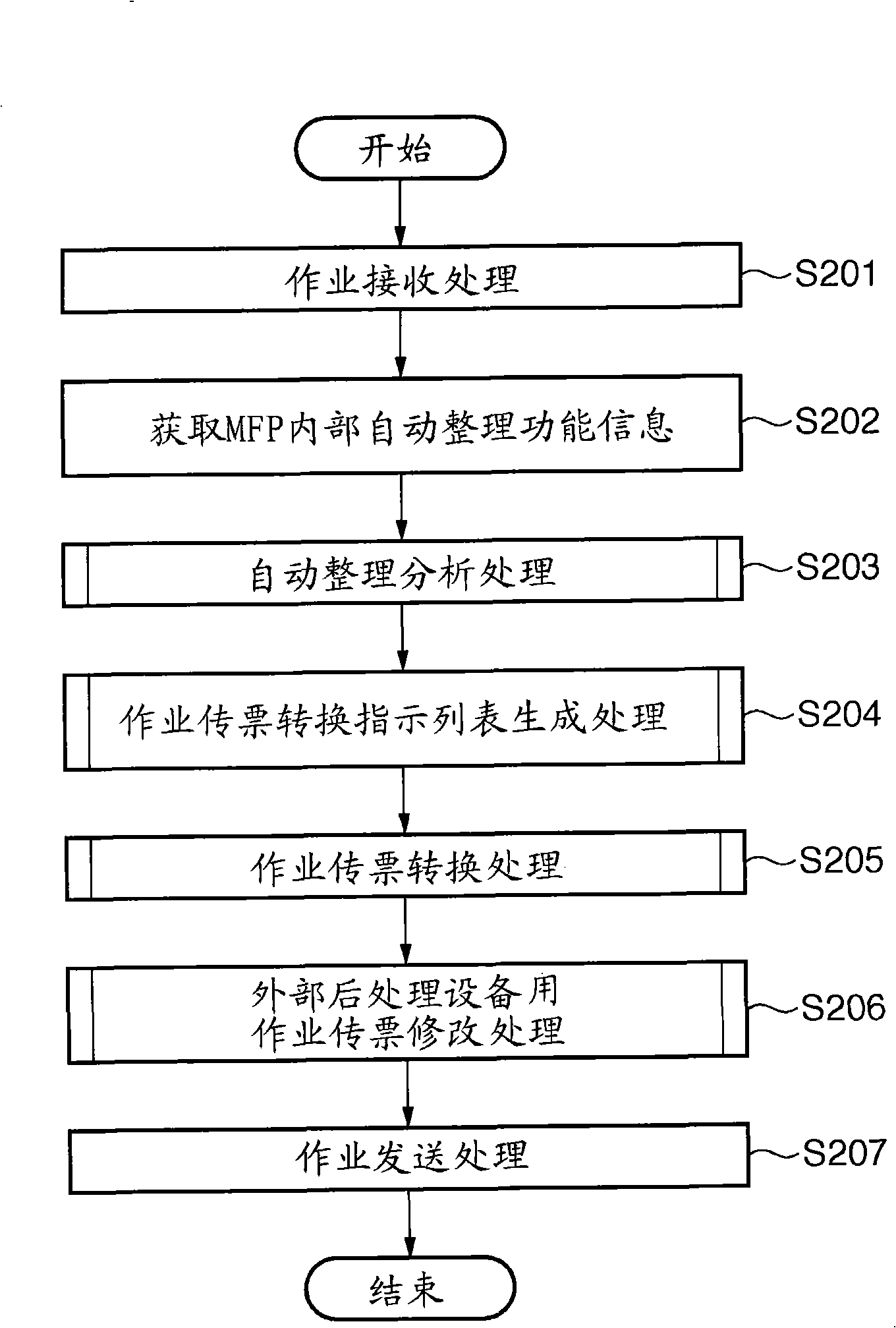

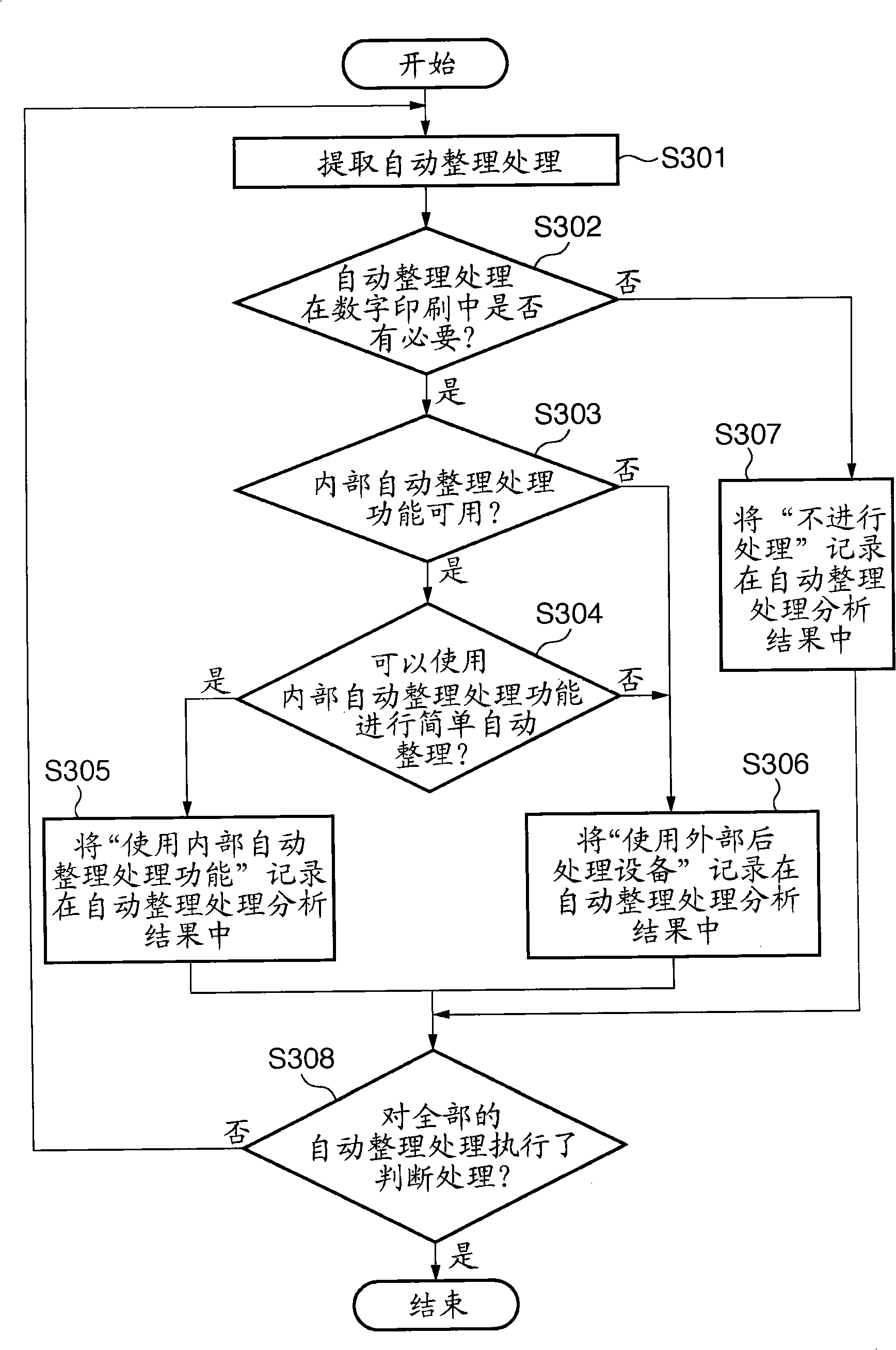

[0028] figure 1 is a diagram showing one example of a system configured including the printing job control apparatus according to the first embodiment of the present invention, a press printing system, and a digital printing system. It should be noted that in the following description, a lithographic printing system may also be referred to as an offset printing workflow system, and a digital printing system may also be referred to as a digital printing workflow system. In addition, a printing job to be used in a graphic printing system is defined as a graphic printing system printing job, and a printing job to be used in a digital printing system is defined as a digital printing system printing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com