Sheet delivery

A technology for paper stacking and gripping teeth, which is used in transportation and packaging, thin material handling, and sending objects. It can solve the problem of not pointing out disturbance torque, and achieve high accuracy and quietness, and reduce the number of components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

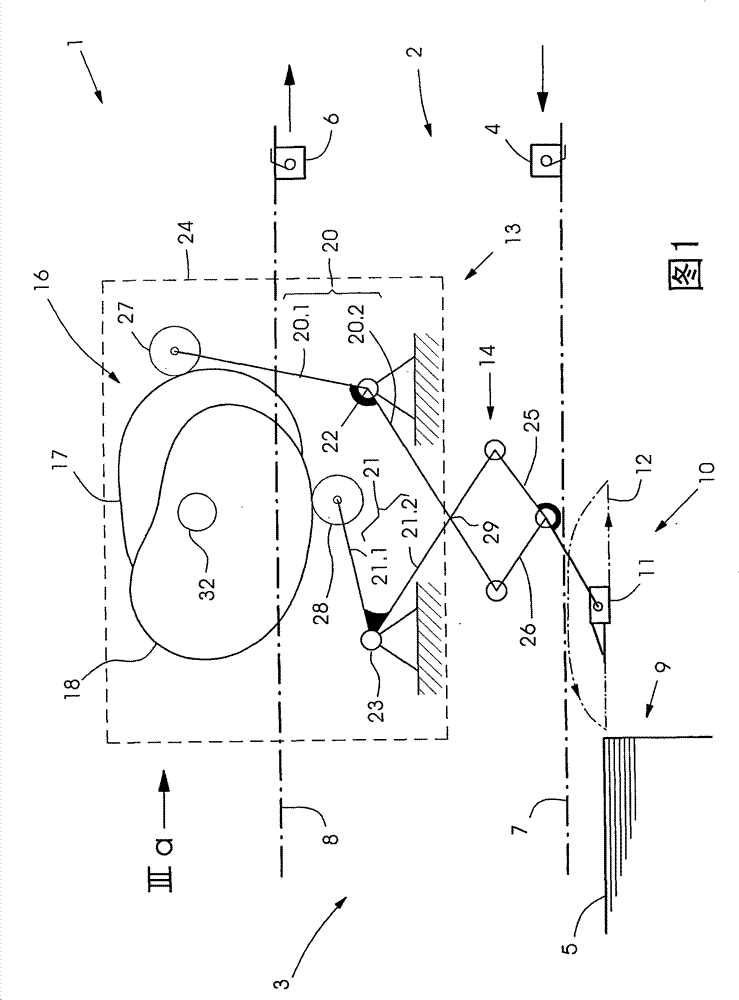

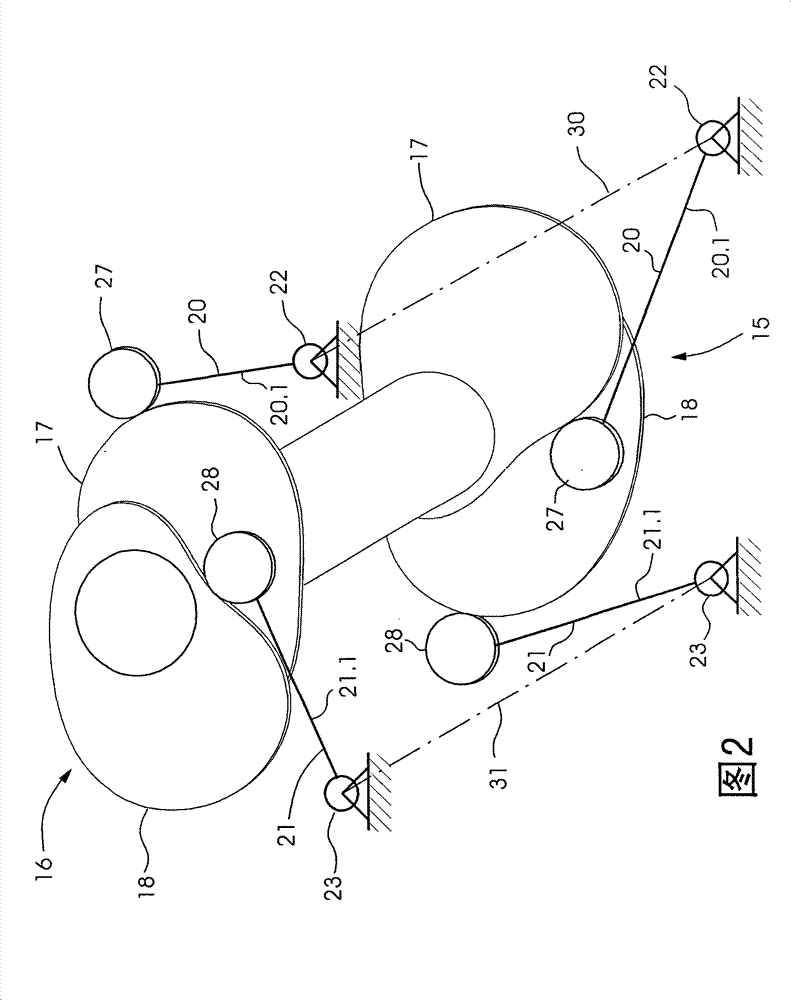

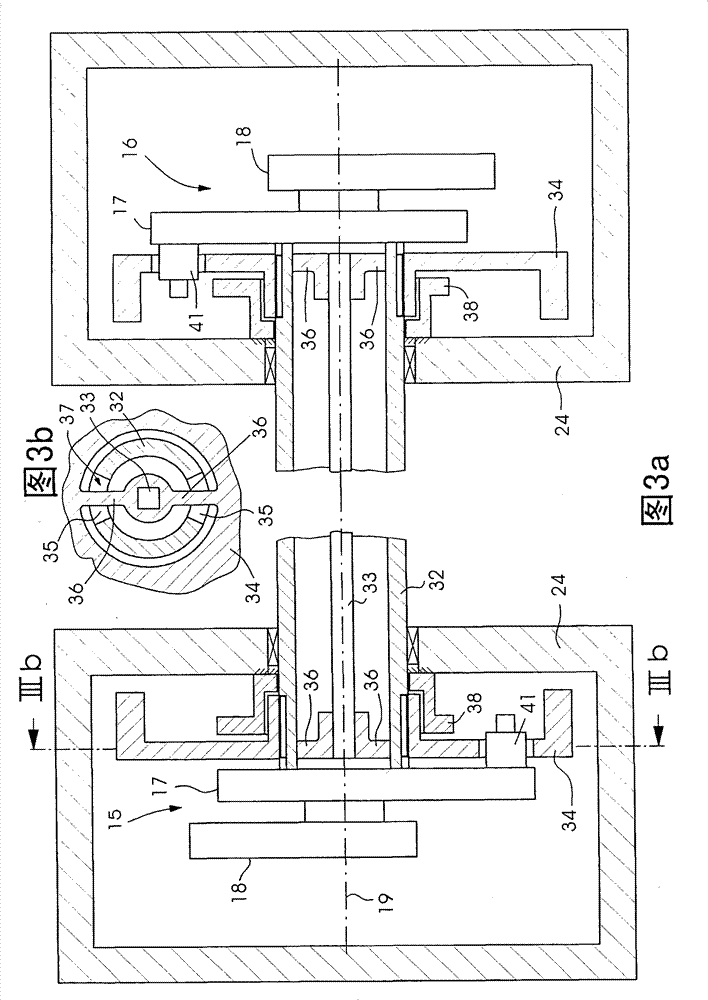

[0025] figure 1 A printing press 1 is shown in detail. The printing press 1 is a sheet-fed offset rotary printing press. The detail shows the delivery 2 of the printing press 1 . The paper delivery device 2 includes a circular conveyor 3, which is a chain conveyor. The endless conveyor 3 comprises, on the drive side and on the operating side, an endless chain for carrying the gripper bridges 4 and an endless chain for carrying the gripper bridges 6 for gripping the printed sheets 5 The leading edge of the gripper tooth bridge 6 is used to grip the trailing edge of the printed sheet 5 . Shown are the advancing branch 7 of the endless chain carrying the gripper bridges at the leading edge of the sheet on one machine side and the return branch 8 of the endless chain carrying the gripper bridges at the trailing edge of the sheet on the same machine side. The forward branches of all four endless chains run in the horizontal direction towards the delivery pile 9 on which the pri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com