Vehicle headlamp

A technology for headlights and vehicles, which is applied to vehicle components, lighting devices, fixed lighting devices, etc., and can solve the problems of high prices of drive motors and electronic components, high manufacturing costs of headlights, etc., and avoid glare and halo phenomena , to achieve the effect of operation reliability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Next, an embodiment of a vehicle headlamp for carrying out the present invention will be described.

[0029] The vehicle headlamps 1, 1 are attached to both left and right end portions of the front portion of the vehicle body, respectively.

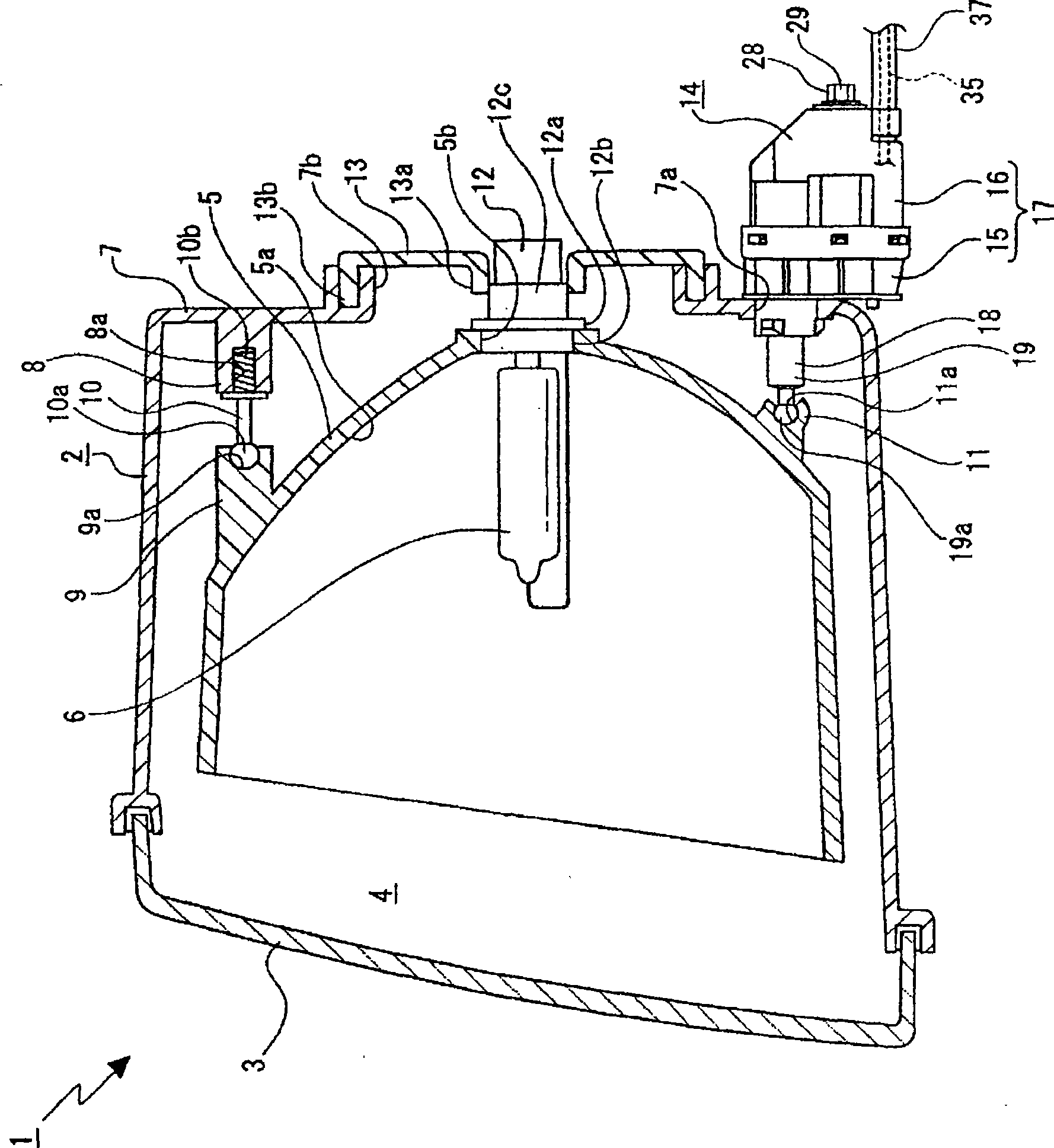

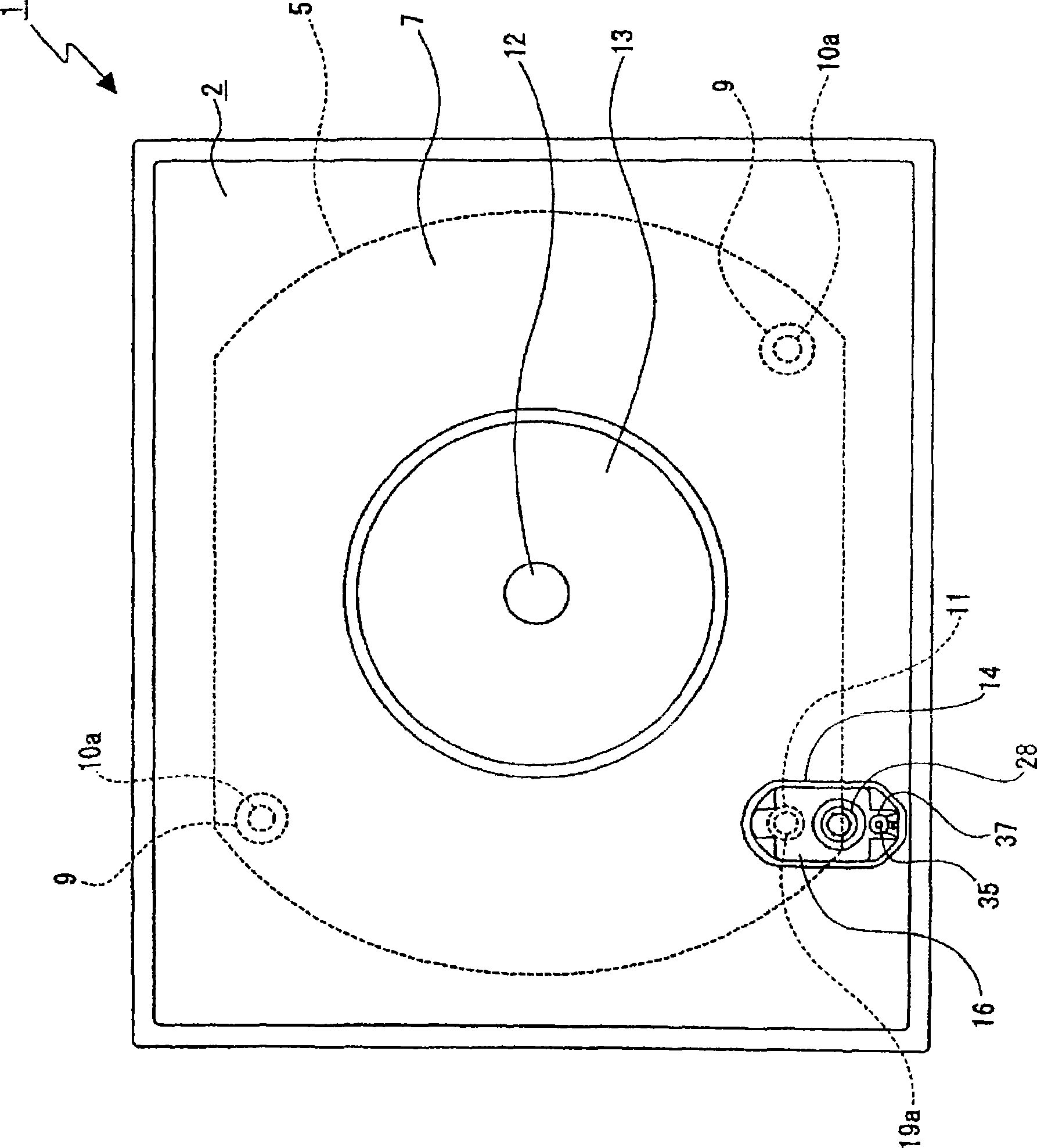

[0030] Vehicle headlamps 1 such as figure 1 As shown, a reflector 5 and a light source 6 installed on the reflector 5 are disposed in the lamp space 4. The lamp space 4 is surrounded by a lamp housing 2 and a lampshade 3, wherein the lamp housing 2 forms The lampshade 3 is in the shape of a container opened forward, and covers the opening of the lamp housing 2 .

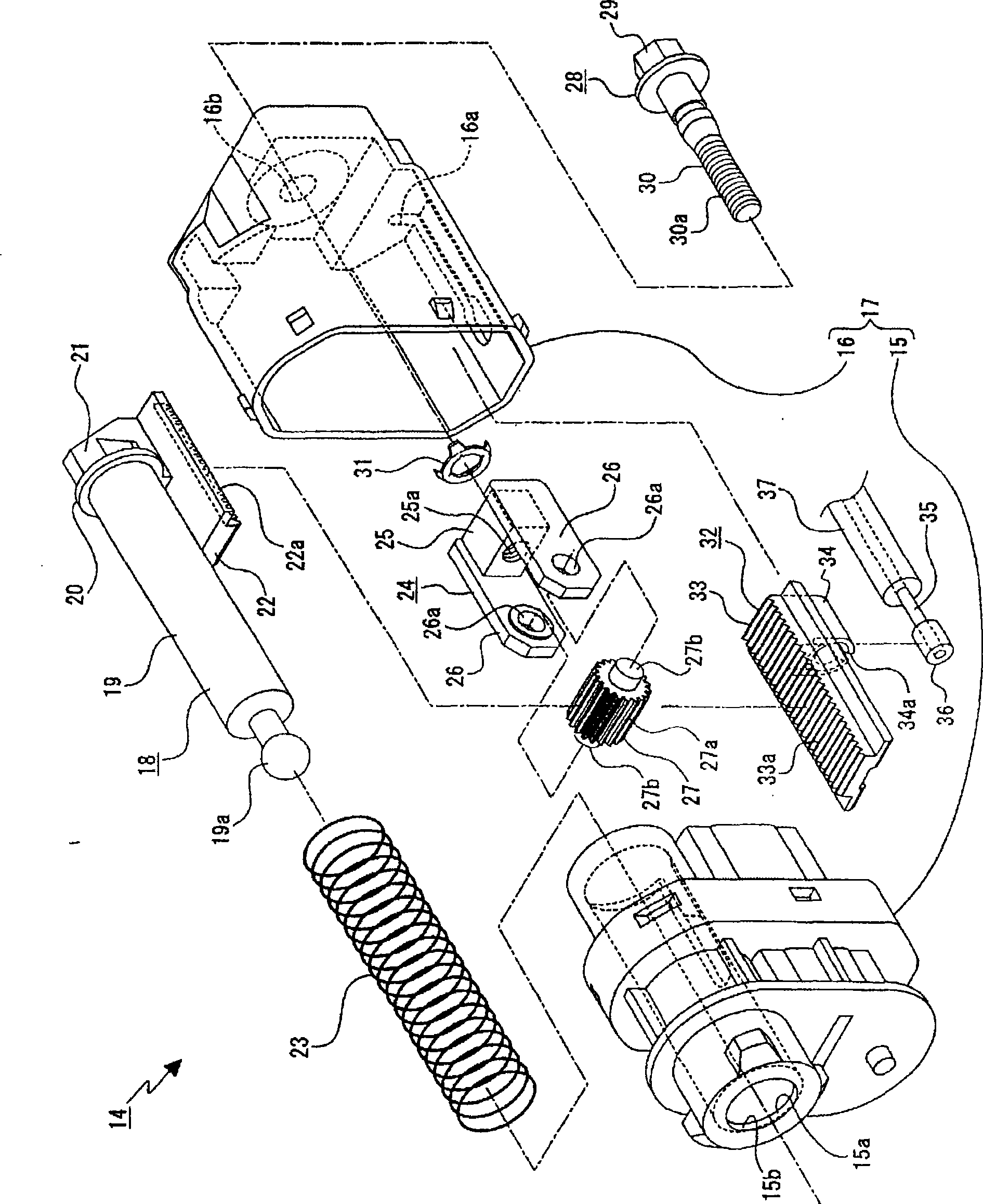

[0031] A through hole 7 a is formed on the lower end portion of the rear surface portion 7 of the lamp housing 2 . On the front surface of the rear surface portion 7 of the lamp housing 2, there are provided supporting protrusions 8, 8 protruding forward, and mounting recesses 8a, 8a are formed on the supporting protrusions 8, 8, and the mounting recesses 8a, 8a face fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com