Winding drum device, winding element and manufacturing method of the winding element

A technology for winding components and reels, which is applied in the directions of electrical components, secondary battery manufacturing, and final product manufacturing, etc., to achieve the effects of suppressing the complexity of the mechanism, suppressing the increase in cost, and suppressing the increase in cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

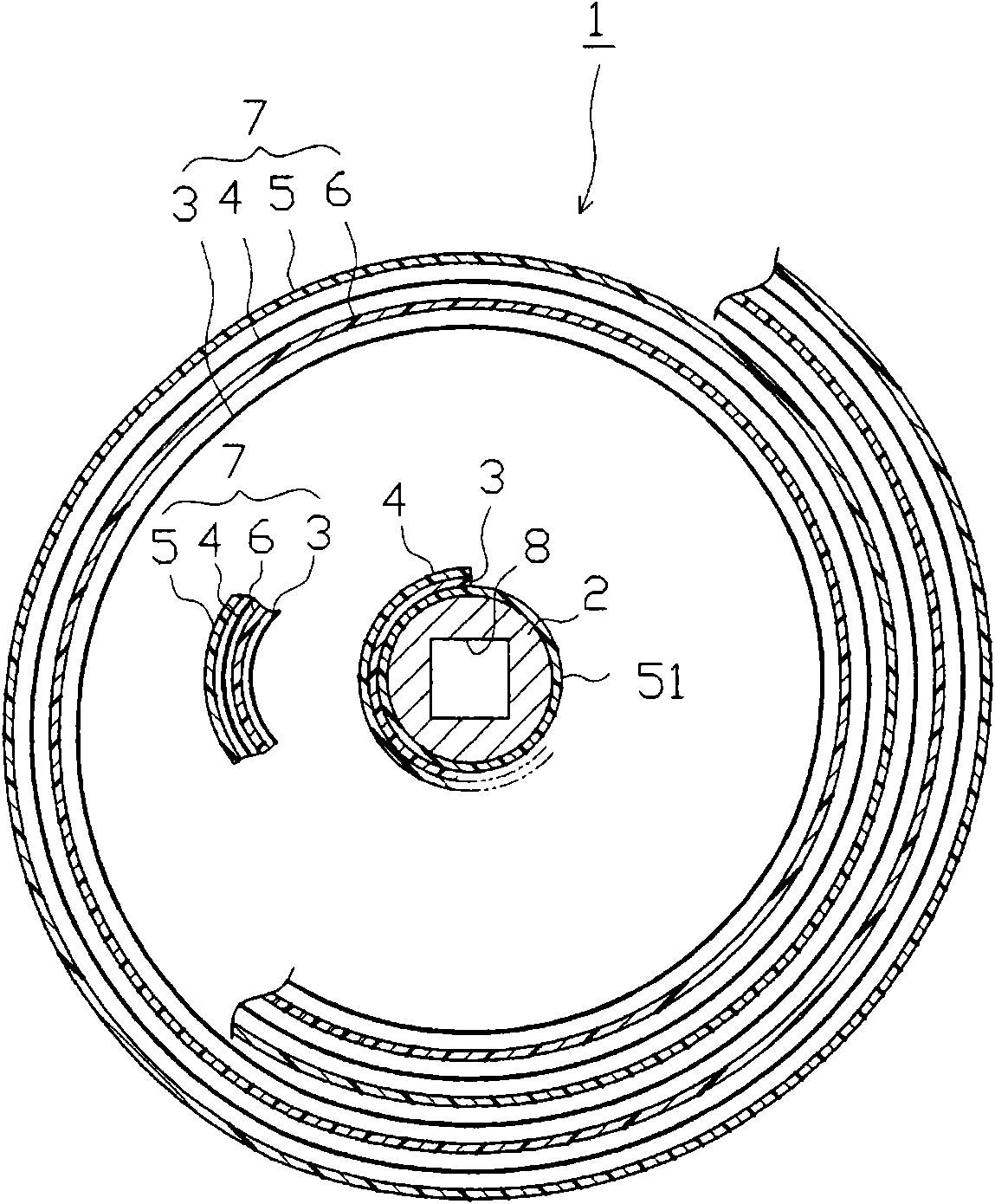

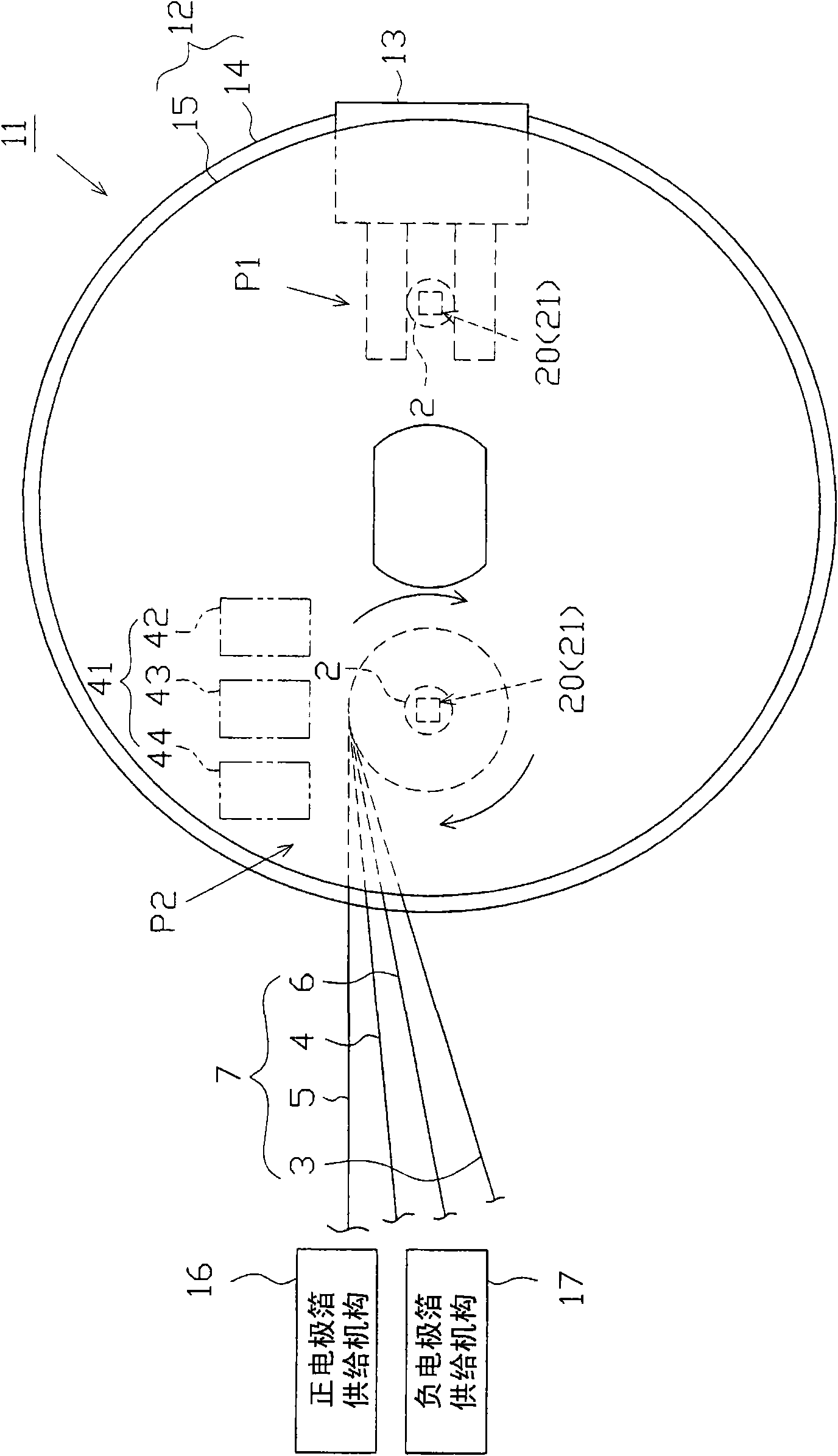

[0082] One embodiment will be described below with reference to the drawings.

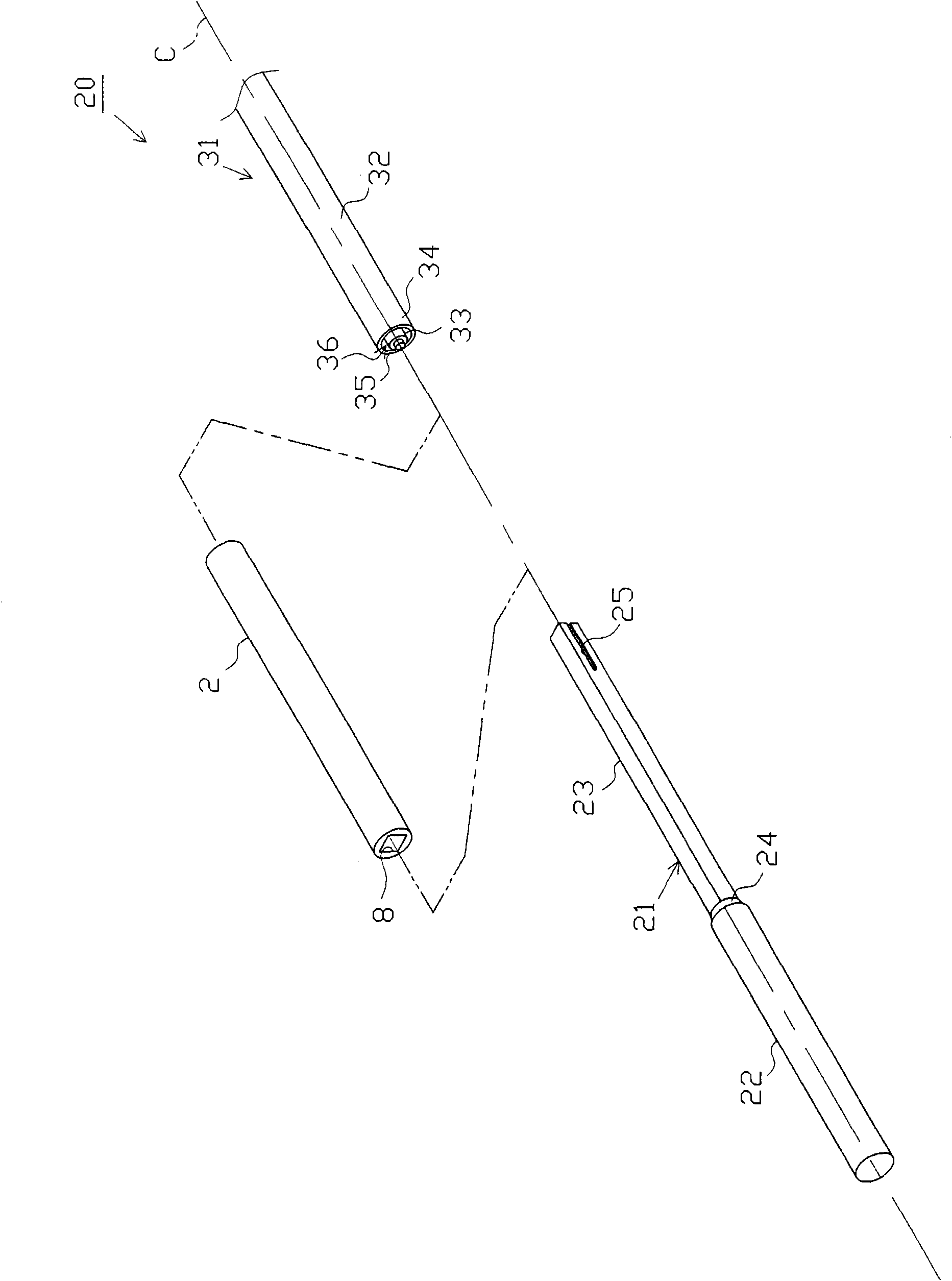

[0083] First, the structure of the lithium ion battery element of the wound element obtained by the winding device of this embodiment is demonstrated. picture figure 1 As shown, a lithium ion battery element (hereinafter referred to as "battery element") 1 is constituted by winding a strip-shaped body 7 with respect to a cylindrical winding mandrel 2, and the strip-shaped body 7 is It consists of two separator sheets 3, 4, positive electrode foil 5, and negative electrode foil 6. In addition, in figure 1 In FIG. 2 , for convenience of description, the separators 3 , 4 , the positive electrode foil 5 , and the negative electrode foil 6 are shown so as to be spaced apart from each other.

[0084] In the present embodiment, the winding mandrel 2 is formed of a sufficiently rigid material (for example, aluminum or the like). In addition, the winding mandrel 2 has an insertion hole 8 (refer to ima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com