Gas sensor

A gas sensor, porous technology, applied in instruments, scientific instruments, measuring devices, etc., can solve problems such as strength reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

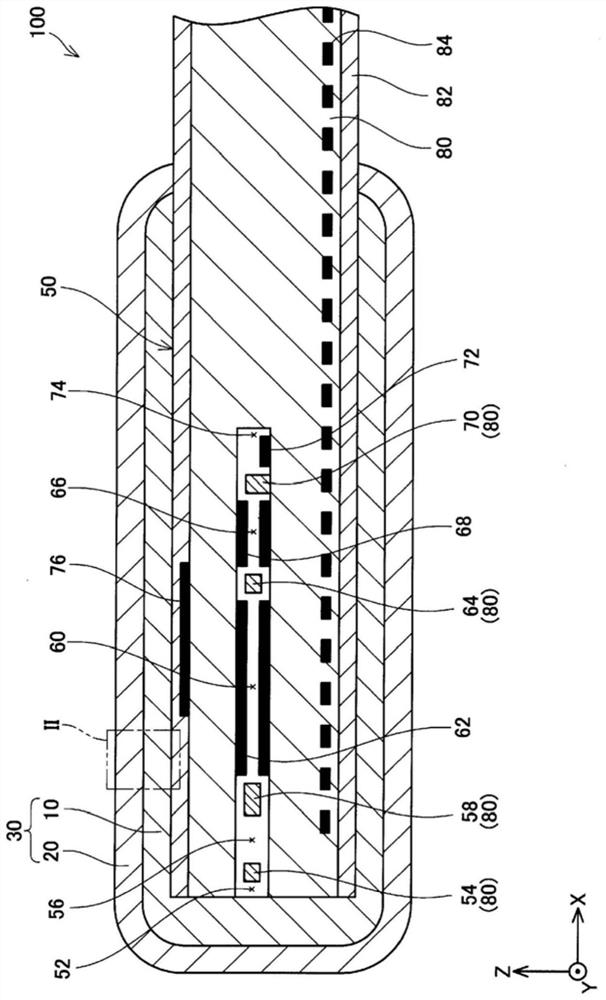

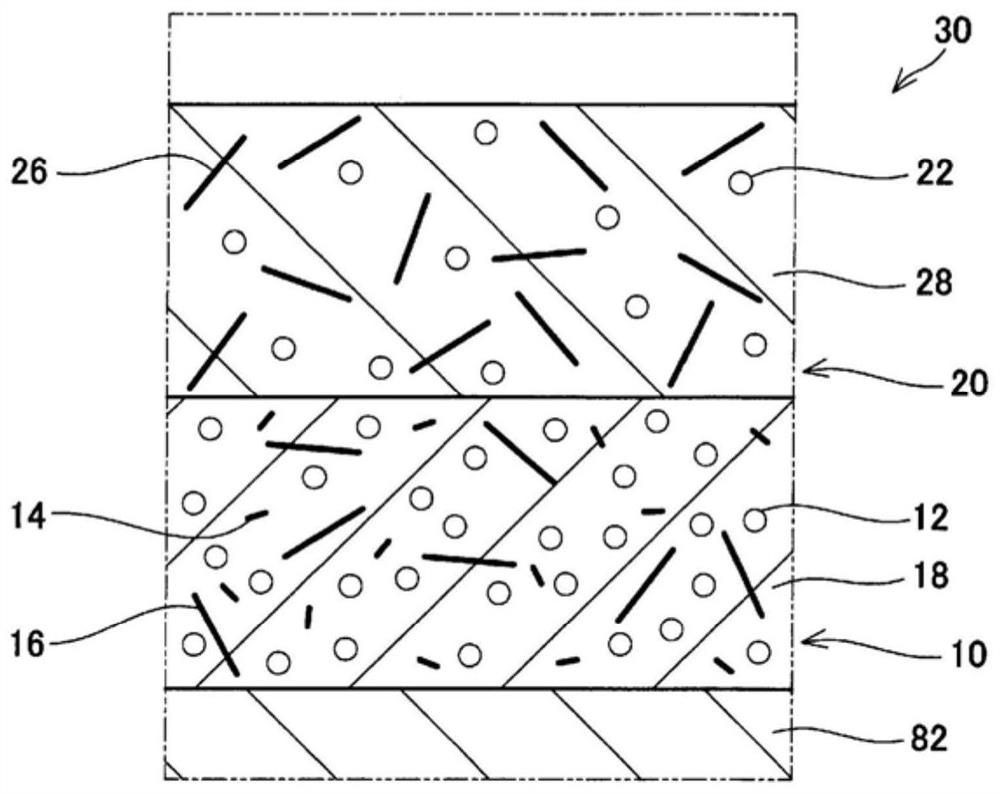

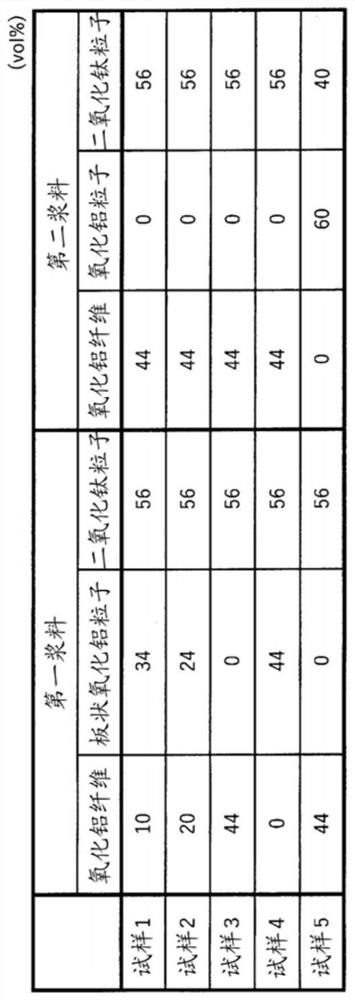

[0044] Five types of gas sensors 100 (samples 1 to 5) having different constituent materials of the porous protective layer 30 were produced, and the characteristics of the gas sensors 100 (porous protective layer 30 ) were evaluated. image 3 The composition of the slurry used to prepare each sample is shown in , Figure 4 The evaluation results of each sample are shown in .

[0045] The porous protective layer 30 is applied to the sensor element 50 by dipping. Specifically, a slurry for the first layer (first slurry) and a slurry for the second layer (second slurry) were prepared, and one end of the sensor element 50 was dipped in the first slurry to form a 300 μm second slurry. layer. Then, the sensor element 50 was placed in a dryer, and the first layer was dried at 200° C. (atmospheric atmosphere) for 1 hour. Next, the portion of the sensor element 50 on which the first layer was formed was dipped in the second slurry to form a 300 μm second layer. Then, the sensor el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com