Gripper for an axminster loom

A technology of yarn gripper and loom, which is applied in the direction of loom, velvet loom, textile, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

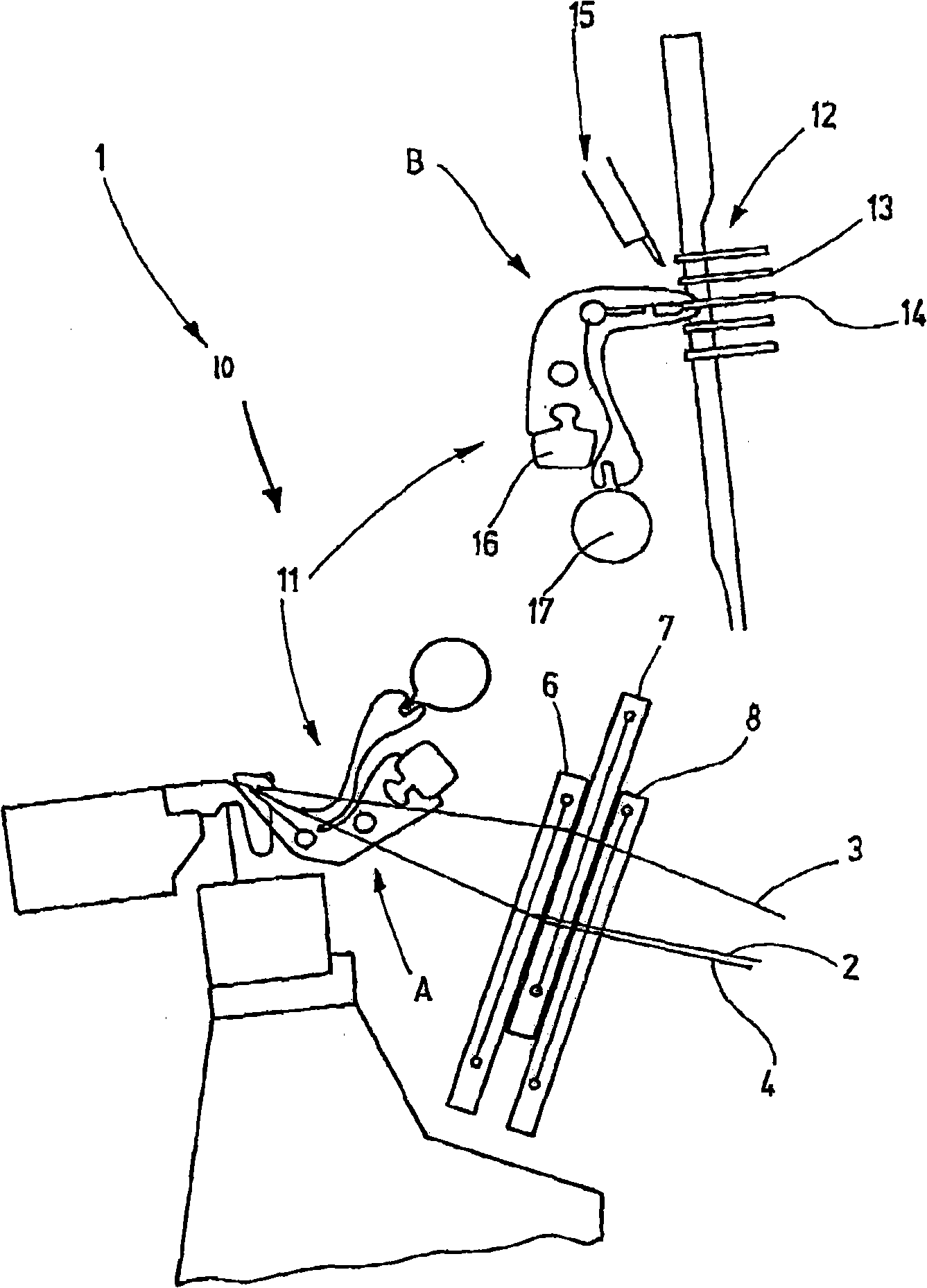

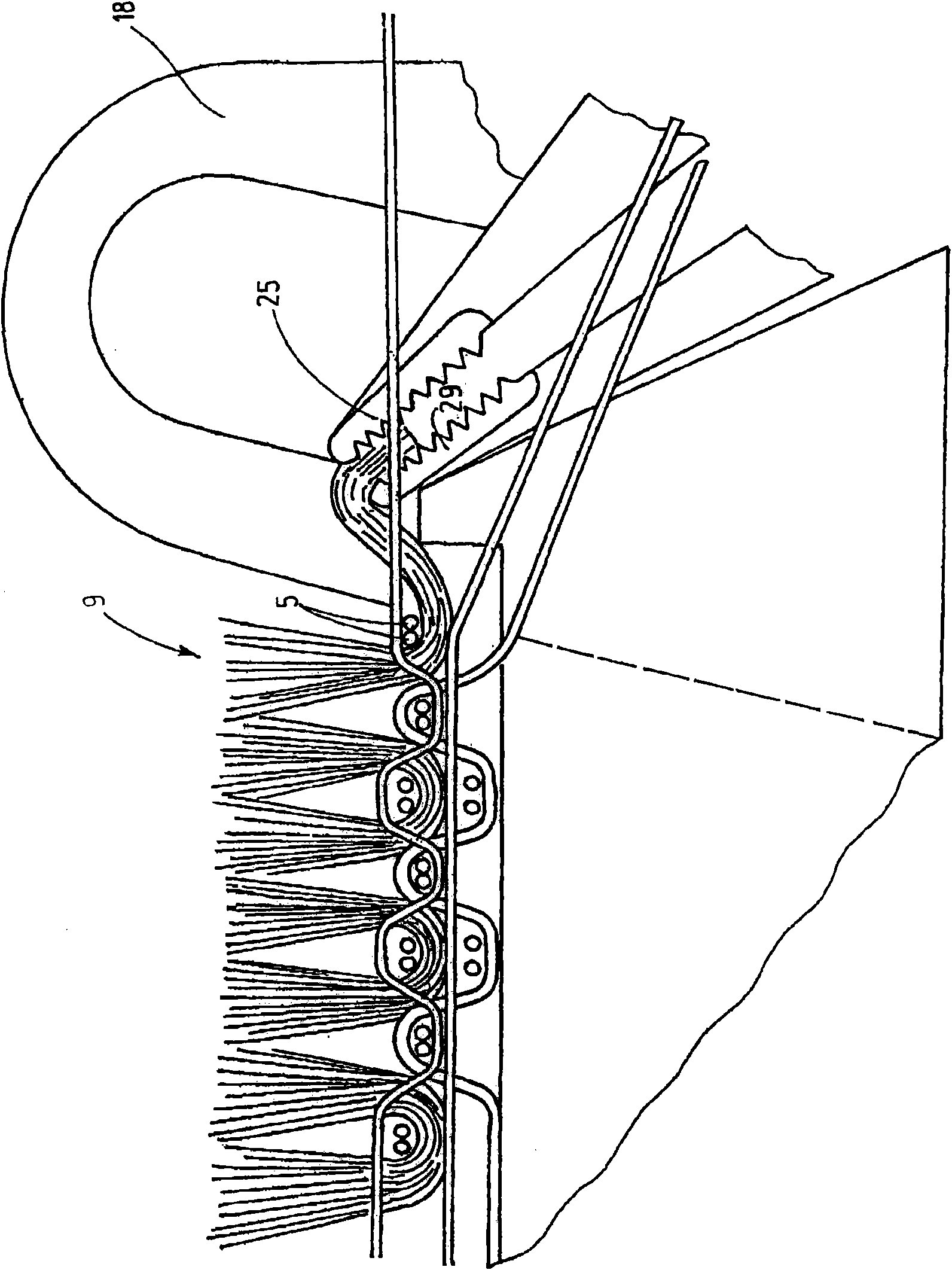

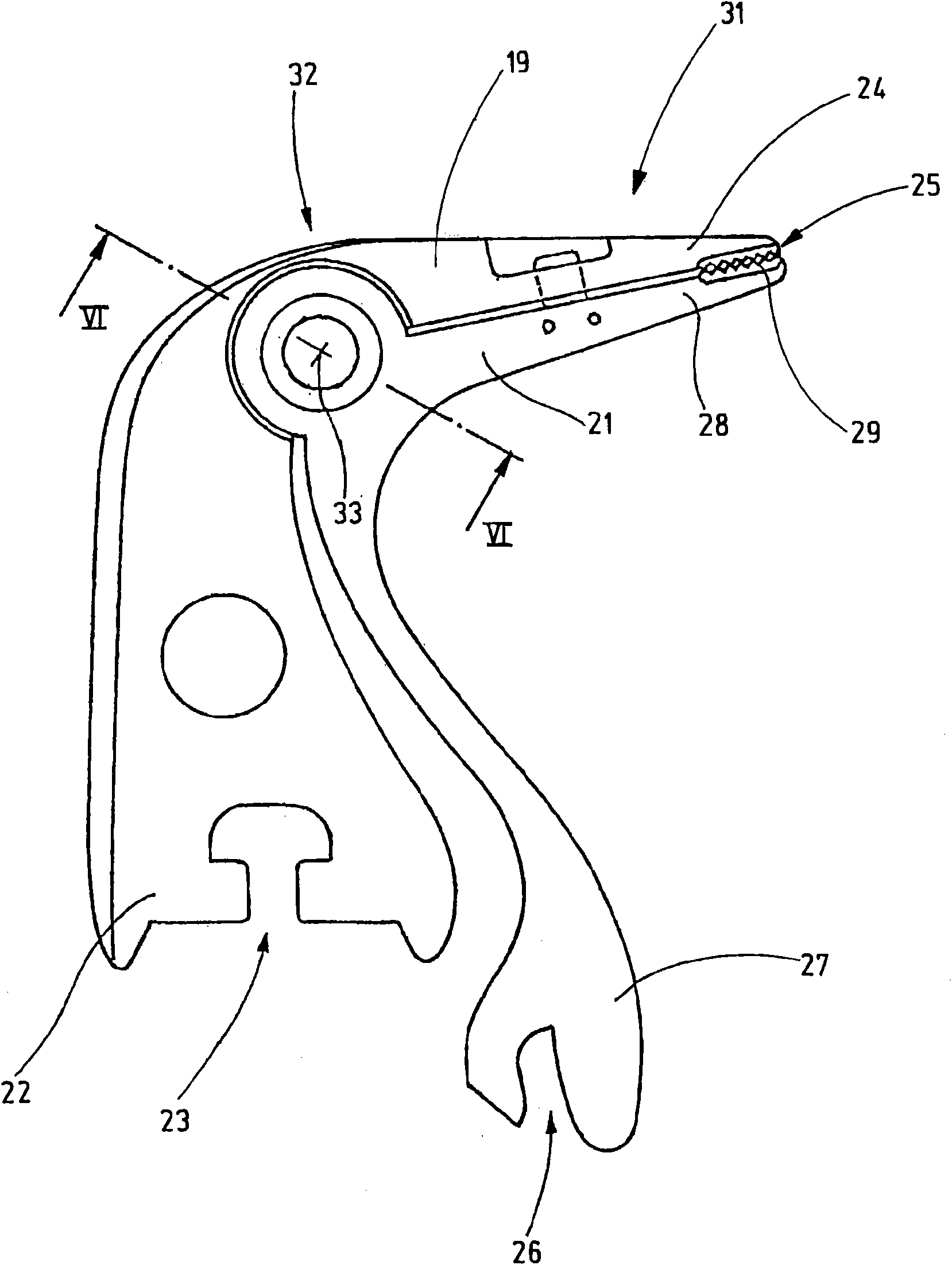

[0068] figure 1 A highly simplified diagram of the Axminster loom. This loom is used for the processing of pile fabrics. It comprises several warp beams (not shown) feeding several warp threads 2,3,4. The shed is formed with warp threads 2, 3, 4, whereby one or mostly two weft threads 5 are loaded into said shed, as figure 2 shown. The sheds are formed with the use of heald frames 6, 7, 8 which guide the warp threads 2, 3, 4 through the healds.

[0069] A gripper device 10 comprising several grippers 11 is used to introduce pre-cut pile yarns 9 into the fabric. The gripper device 10 comprising the gripper 11 is movable between its first position A, in which it introduces the pile yarn 9 into the fabric, and its second position B, in which it withdraws the pile yarn from the thread guide 12 . The yarn guide 12 is able to hold several yarns 13, 14 of different colors at the ready and can be controlled in such a way as to retrieve the desired yarn respectively, for example...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap