Self-destruction type anti-counterfeiting bottle cap

An anti-counterfeit bottle cap and self-destruction technology, which is applied in the field of bottle caps, can solve problems such as irreversibility, affect the appearance of the bottle cap, and overall damage, and achieve the effect of ensuring sealing performance, good appearance, and reliable sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

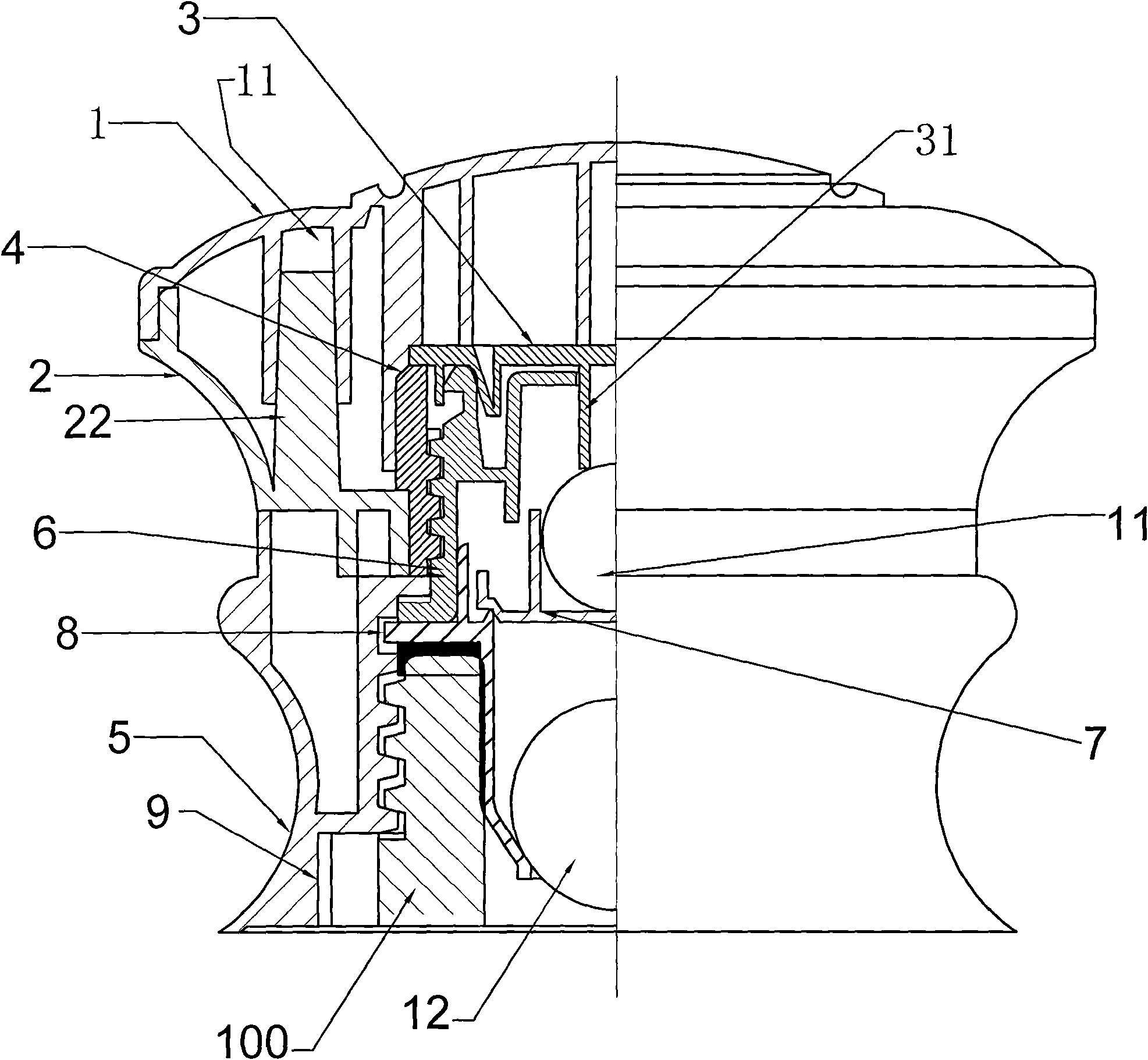

[0033] Such as figure 1 , Self-destruct anti-counterfeiting bottle caps, including:

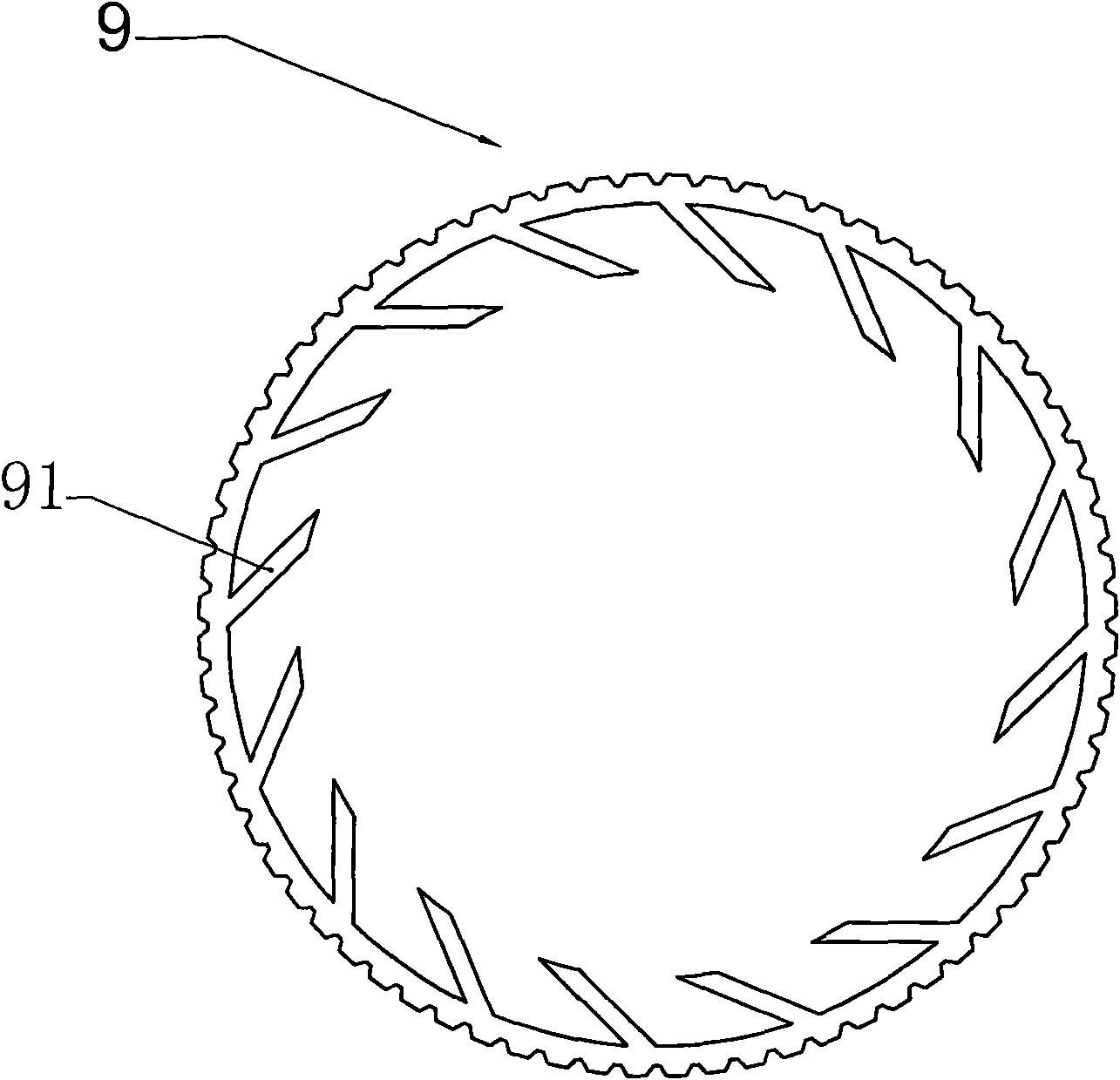

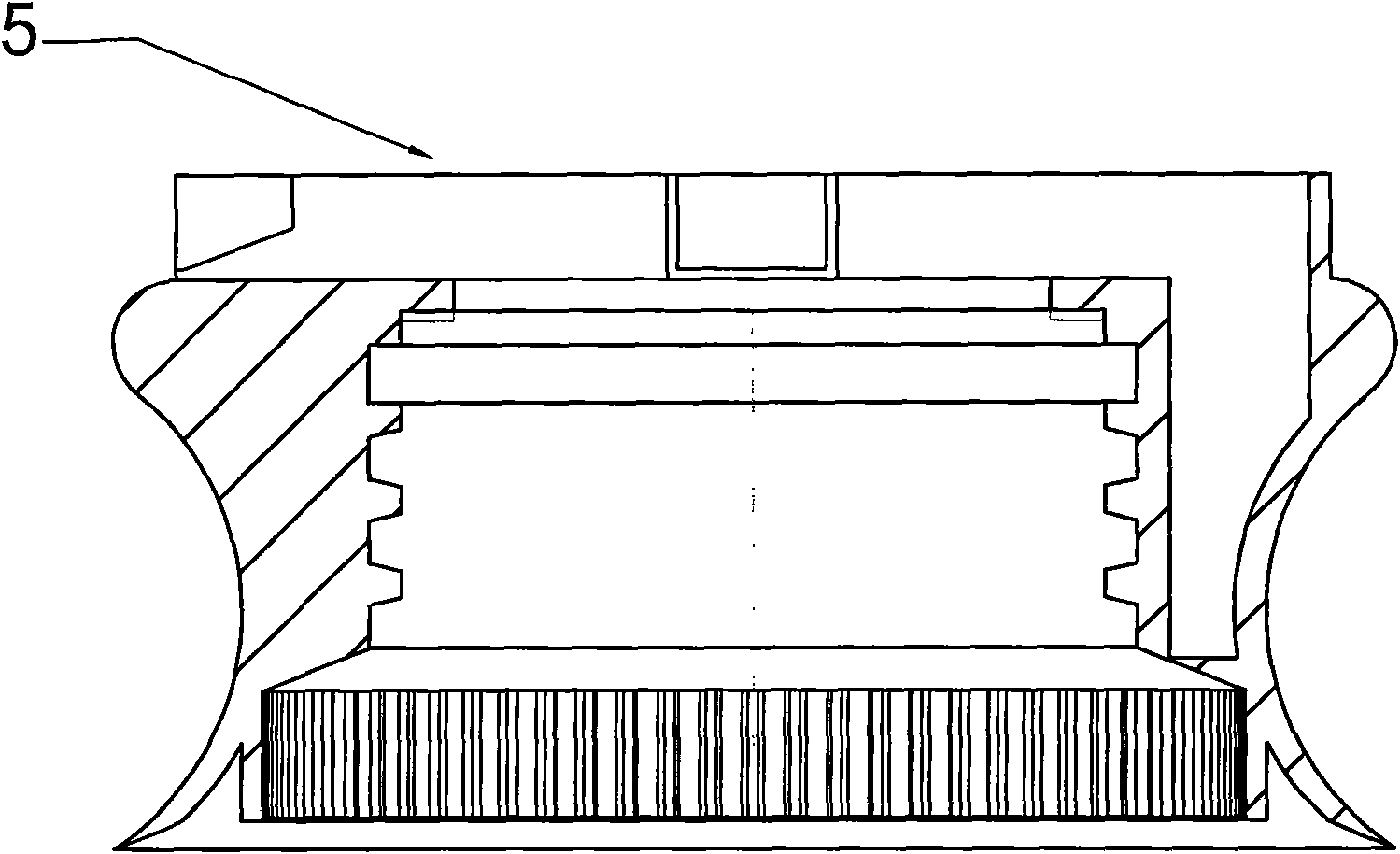

[0034] Outer body 5 (combined with image 3 ), its inner surface is cylindrical, and the inner thread in the middle part of the outer main body 5 has an internal thread that cooperates with the peripheral thread of the bottleneck. see Figure 4 , there are four inwardly protruding separable bodies 51 on the inner side of the upper part of the outer body 5, and the four separable bodies 51 are connected to the outer body 5 in breakpoints. Push it out.

[0035] inner plug 8 (combined with Image 6 ), which is columnar with upper and lower openings, the lower opening is small, the upper opening is large, the inner plug is stuck between the outer body 1 and the bottleneck 100, the large glass ball 12 is placed in the inner plug 8, and the lower opening of the inner plug 8 is smaller than The diameter of the large glass ball 12.

[0036] Small transparent part 7, its frame is on the upper en...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap