Civil blasting material storeroom monitoring substation and sensor being capable of being connected with coal mine safety monitoring system

A monitoring substation and monitoring system technology, applied in the direction of comprehensive factory control, comprehensive factory control, mining equipment, etc., can solve the problem that the coal mine explosives warehouse cannot be monitored in real time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

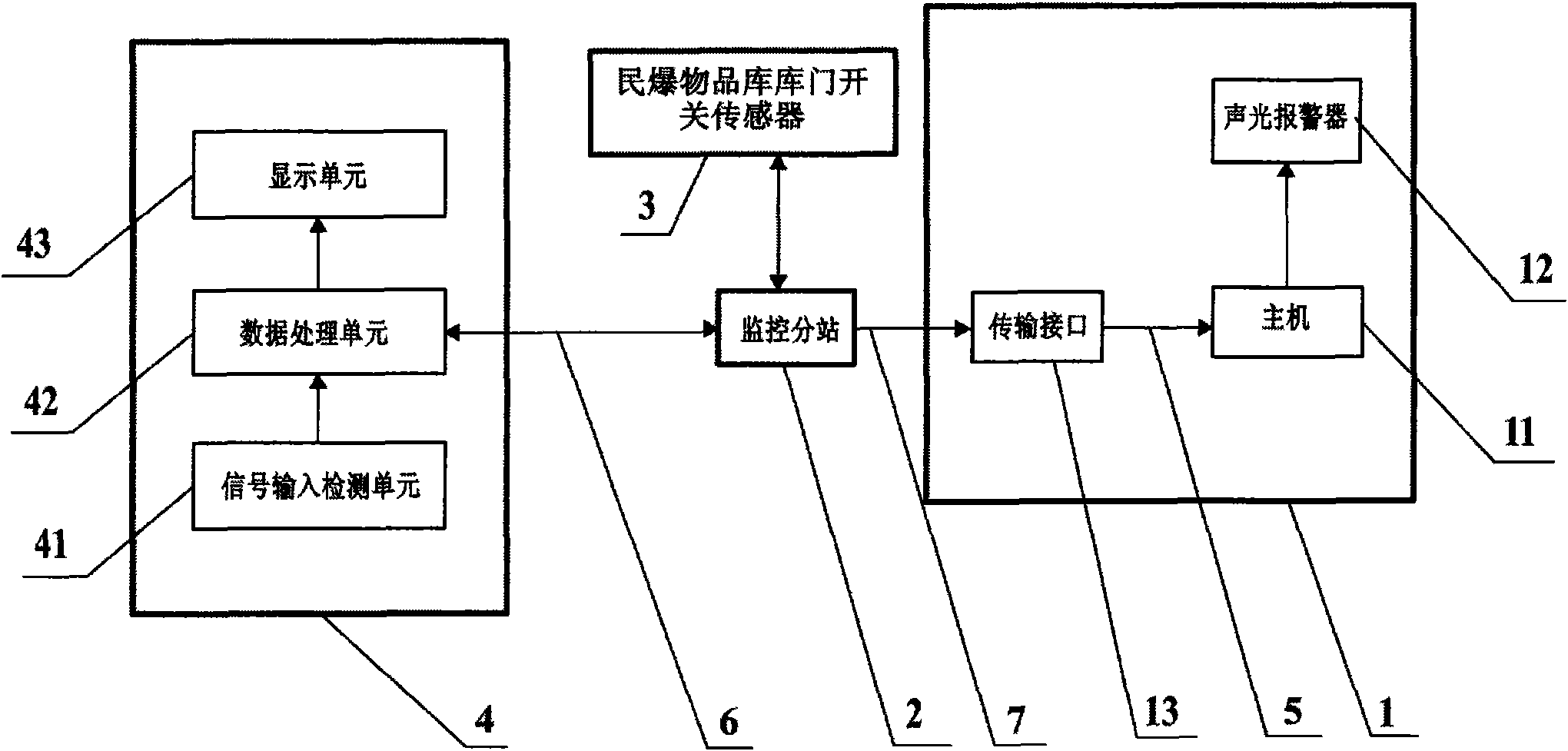

[0021] The structure of the present invention will be further described below in conjunction with the accompanying drawings.

[0022] figure 1 Among them, the monitoring sub-stations and sensors of the civil explosives warehouse that can be connected to the coal mine safety monitoring system include: 1. The current safety monitoring system; 2. Monitoring sub-stations; 3. The door switch sensor of the civil explosives warehouse; 4. Detonators and explosives barcode information collector; 5. RS485 communication cable; 6. MHYVR mine communication cable; 7. MHY32 communication cable.

[0023] Main components in the current safety monitoring system (1): 11. host computer; 12. sound and light alarm; 13. transmission interface;

[0024] Main components in the barcode information collector (4) of detonators and explosives: 41. signal input monitoring unit; 42. data processing unit; 43. display unit.

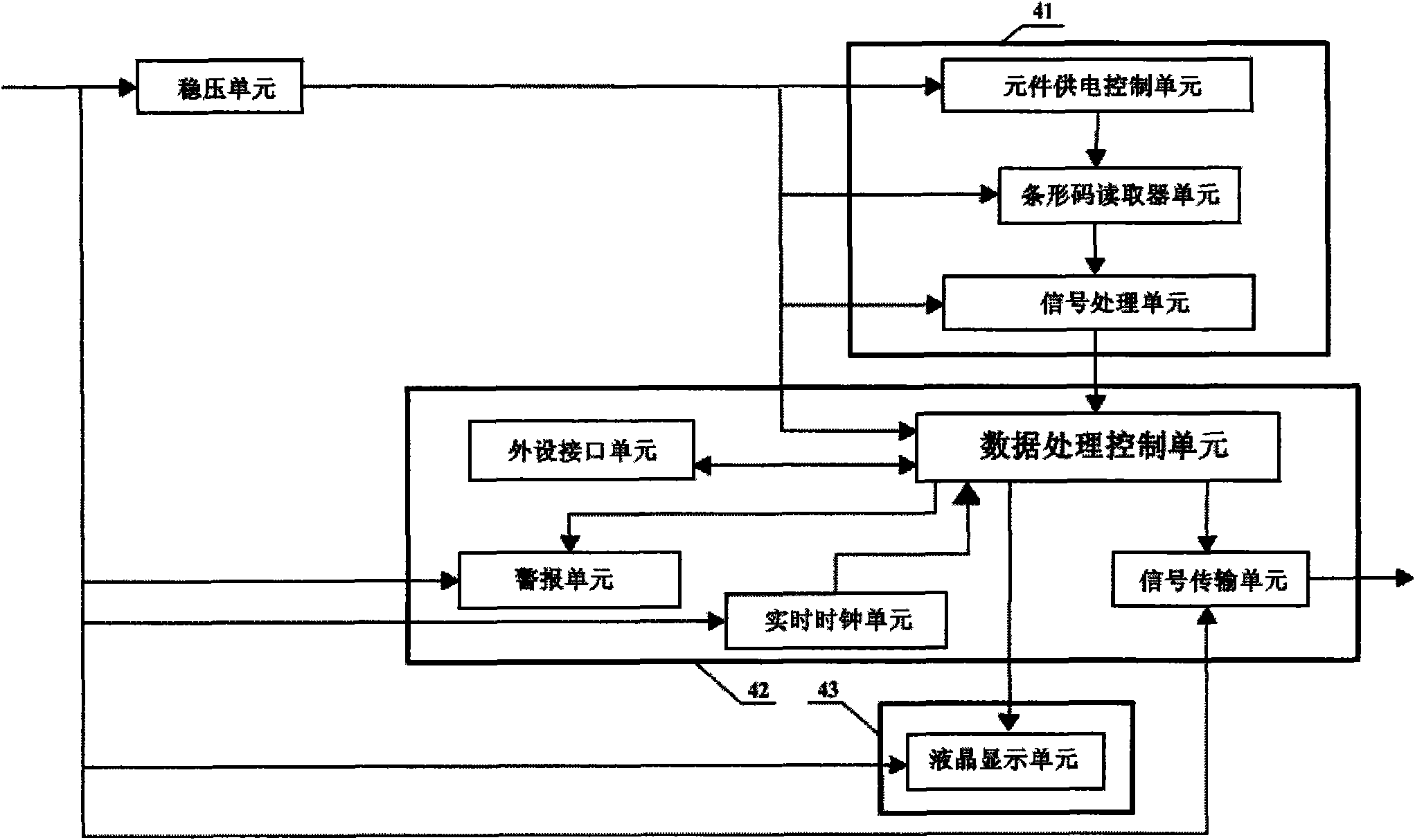

[0025] figure 2 Among them, the barcode information collector of detonators and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com