Strap head

A technology of ends and belts, which is applied in the direction of clothing, shoe bindings, shoes, etc., can solve problems such as fragmentation, hooking clothing, and increasing the amount of consumables, so as to improve service life, increase stability, and avoid falling off Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

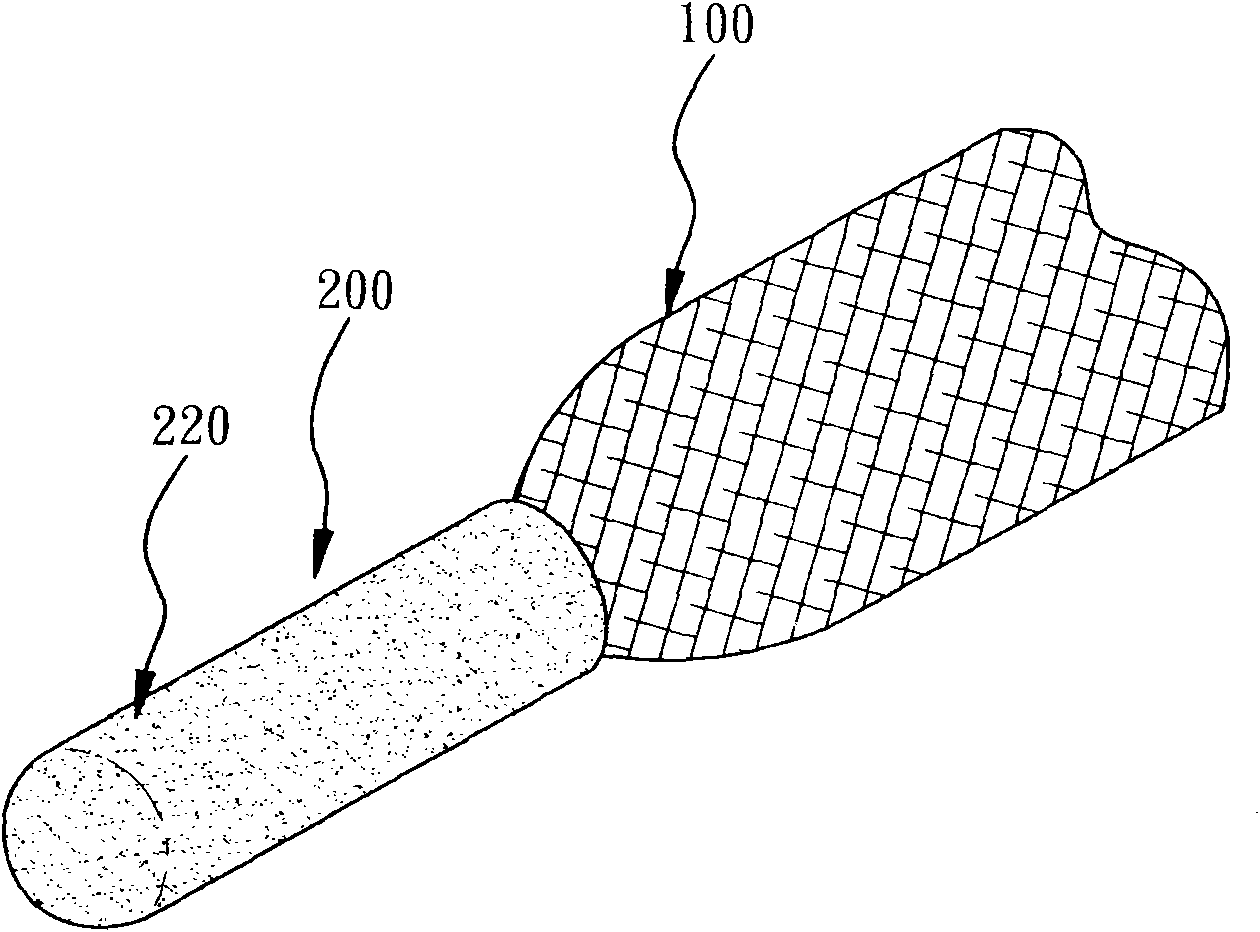

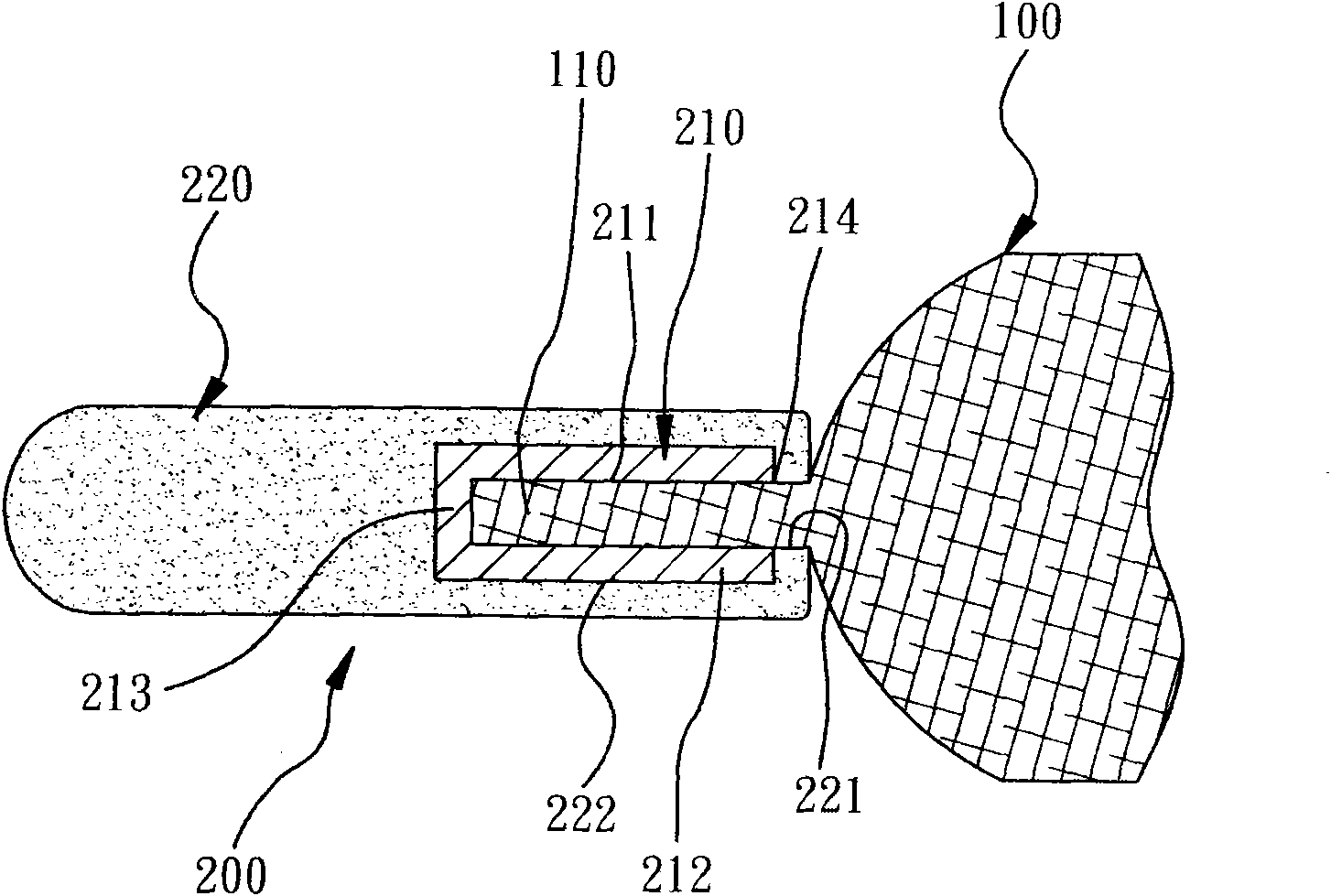

[0037] refer to figure 1 and figure 2 , the first embodiment of the belt end of the present invention is for connecting to the end 110 of the belt 100 . The belt end 200 includes a bundle layer 210 and an elastic layer 220 .

[0038] The binding layer 210 is a hard plastic material, and has a peripheral wall 212 extending along an axis and defining a chamber 211, and a closed end 213 and an opening 214 formed on both sides of the peripheral wall 212, the belt body 100 The opening is inserted into the chamber 211 of the binding layer 210 . The binding layer 210 is thermoplastic rubber (TPR, thermoplastic rubber), polyurethane (PU, Polyurethane), thermoplastic polyurethane (TPU, Thermoplastic Polyurethane) and acrylonitrile-butadiene-styrene polymer (ABS, acrylonitrile-butadiene- any of styrene copolymers).

[0039] The elastic layer 220 is soft rubber material. The elastic layer 220 has an opening 221 and a space 222 extending inward from the opening 221 . The elastic la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com