Multi-folding umbrella rib

An umbrella rib and extension technology, which is applied in the field of umbrella rib structure improvement, can solve the problems of inconvenient manufacture, easy hooking of umbrella cloth, etc., and achieve the effects of increasing stability and service life, and preventing the position deviation of the first joint.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

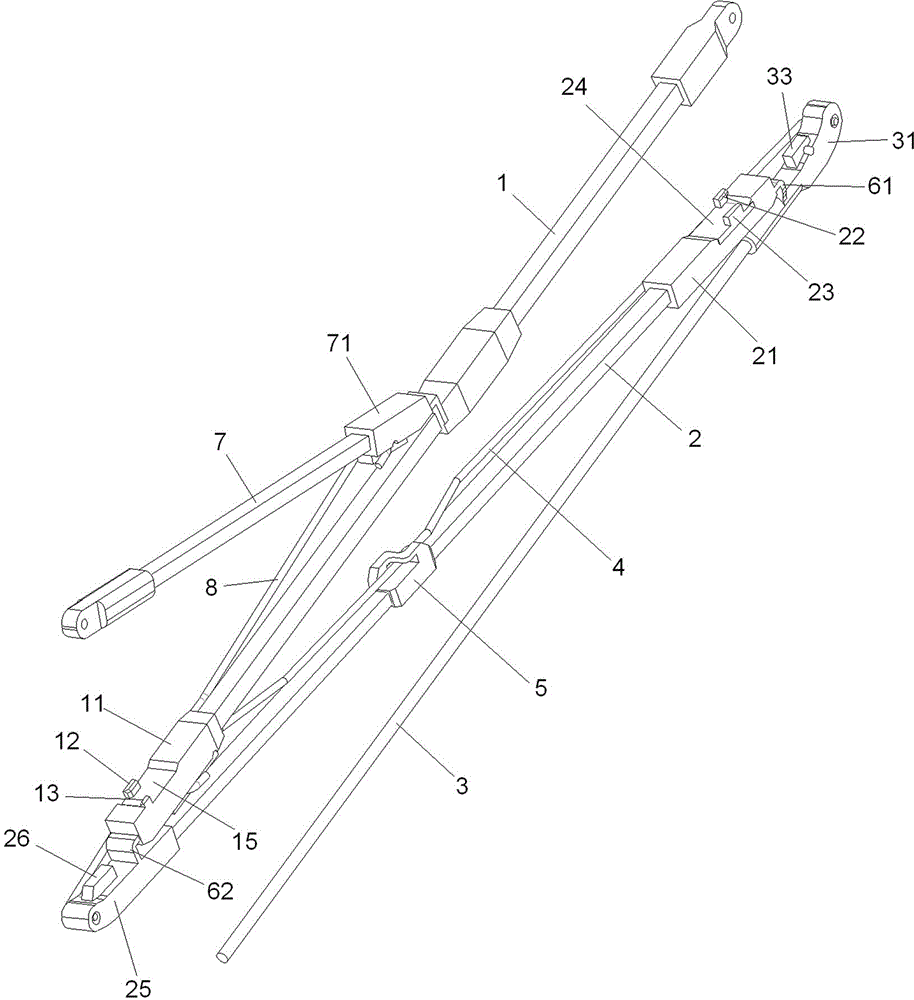

[0024] The ribs of the multi-fold umbrella of the present invention can be applied to multi-fold umbrellas that are opened automatically or by hand. The following uses a three-fold umbrella as an example to describe in detail with reference to the accompanying drawings.

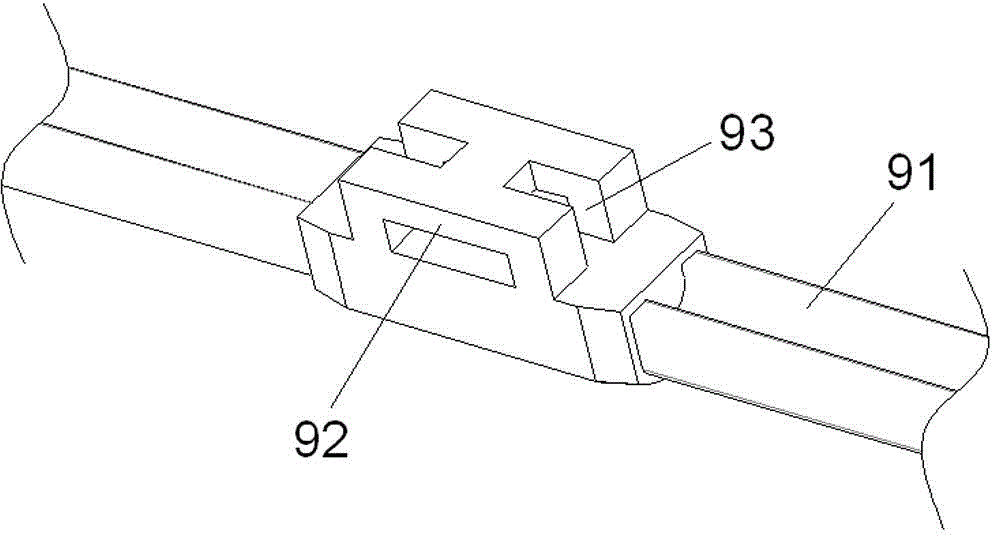

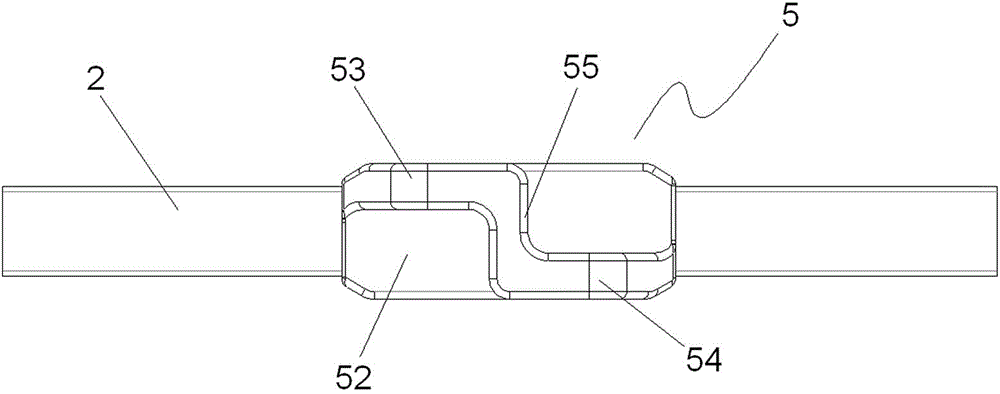

[0025] Such as figure 2 As shown, the ribs of the multi-fold umbrella of the present invention include: the first rib 1, the second rib 2 and the third rib 3 connected sequentially from the inside to the outside, and the outer end is connected to the middle of the first rib 1 The fourth umbrella rib 7, backguy 4 and backguy 8. The inner end of the third rib is fixedly provided with a first joint 31, the inner and outer ends of the second rib 2 are respectively fixed with a fourth joint 25 and a second joint 21, and the outer end of the first rib 1 is fixed with a The third joint 11 and the fifth joint 71 are fixed on the outer end of the fourth rib 7, and the above joints are usually made of plastic materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com