Pasting strip for sealing upper substrate and lower substrate of plasma display panel and sealing method thereby

A technology of plasma display screen and lower substrate, applied in the field of gas discharge, can solve the problems of easy occurrence of defects, high precision requirements, and many equipments, and achieves the effect of completely controlled appearance, saving drying and inspection processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific implementation manners of the present invention will be described in detail below with reference to the accompanying drawings.

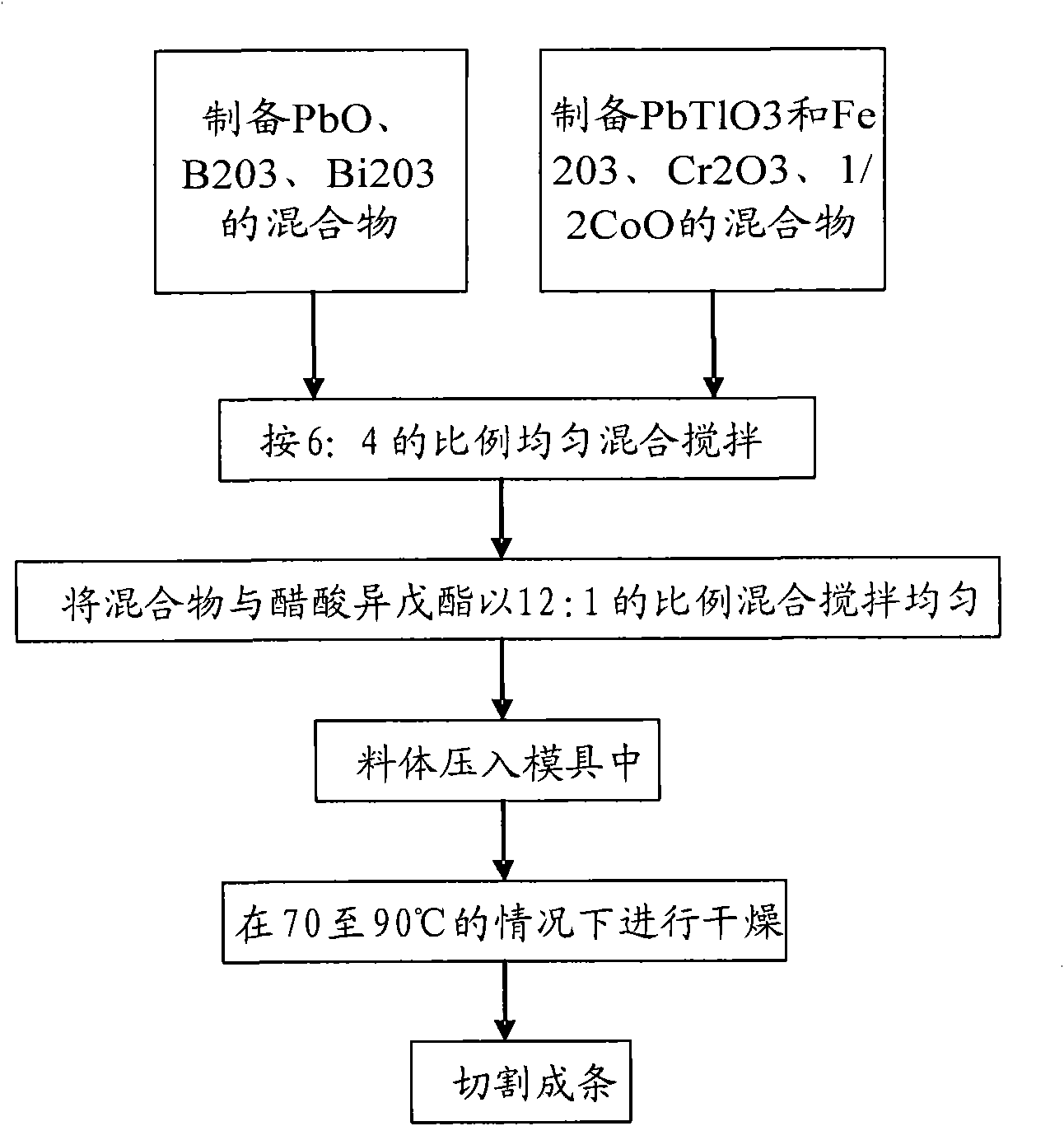

[0014] figure 1 It is a schematic flowchart of a method for preparing an application strip for sealing upper and lower substrates of a plasma display screen according to an embodiment of the present invention. Such as figure 1 As shown, the method includes: preparing PbO, B 2 o 3 、 Bi 2 o 3 The mixture, its weight proportion ratio is about 90 parts, 9 parts, 1 part; Preparation of PbT10 3 and Fe 2 o 3 、Cr 2 o 3 , 1 / 2CoO mixture, its weight ratio is about 80 parts, 20 parts; PbO, B 2 o 3 、 Bi 2 o 3 A mixture of and PbTlO 3 , Fe 2 o 3 、Cr 2 o 3 , 1 / 2 CoO mixture in a ratio of 6:4 (weight ratio); then mix this mixture with isoamyl acetate in a ratio of 12:1, and press the uniformly stirred material into the mold , dried at 70°C, taken out after drying, and cut into strips of various specifications as required.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com