Stop element system and stop element for concrete formwork

A technology of concrete formwork and stopper, which is applied to the connection of formwork/formwork/work frame, the on-site preparation of building components, and construction, etc., can solve problems such as high cost and achieve the effect of reducing the number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

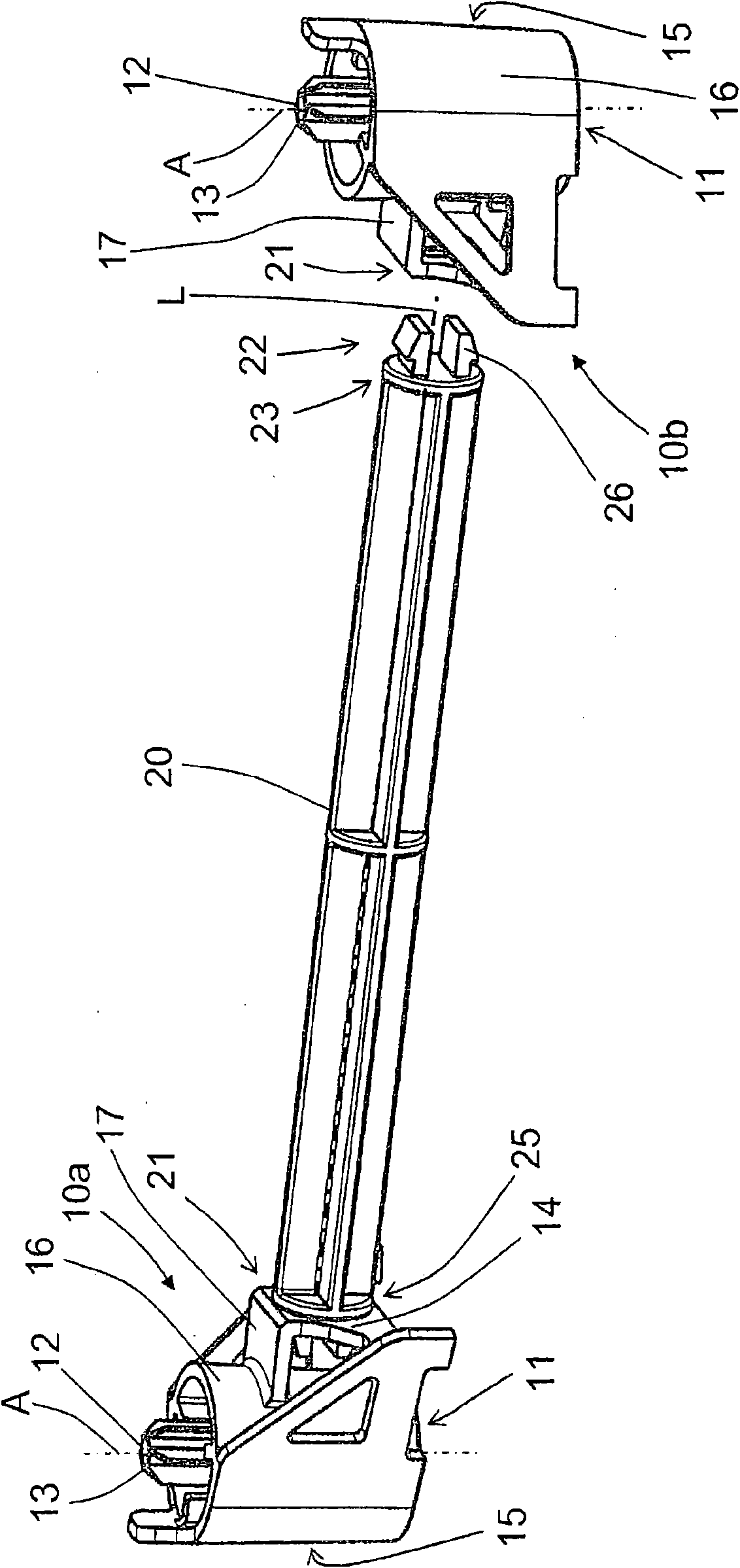

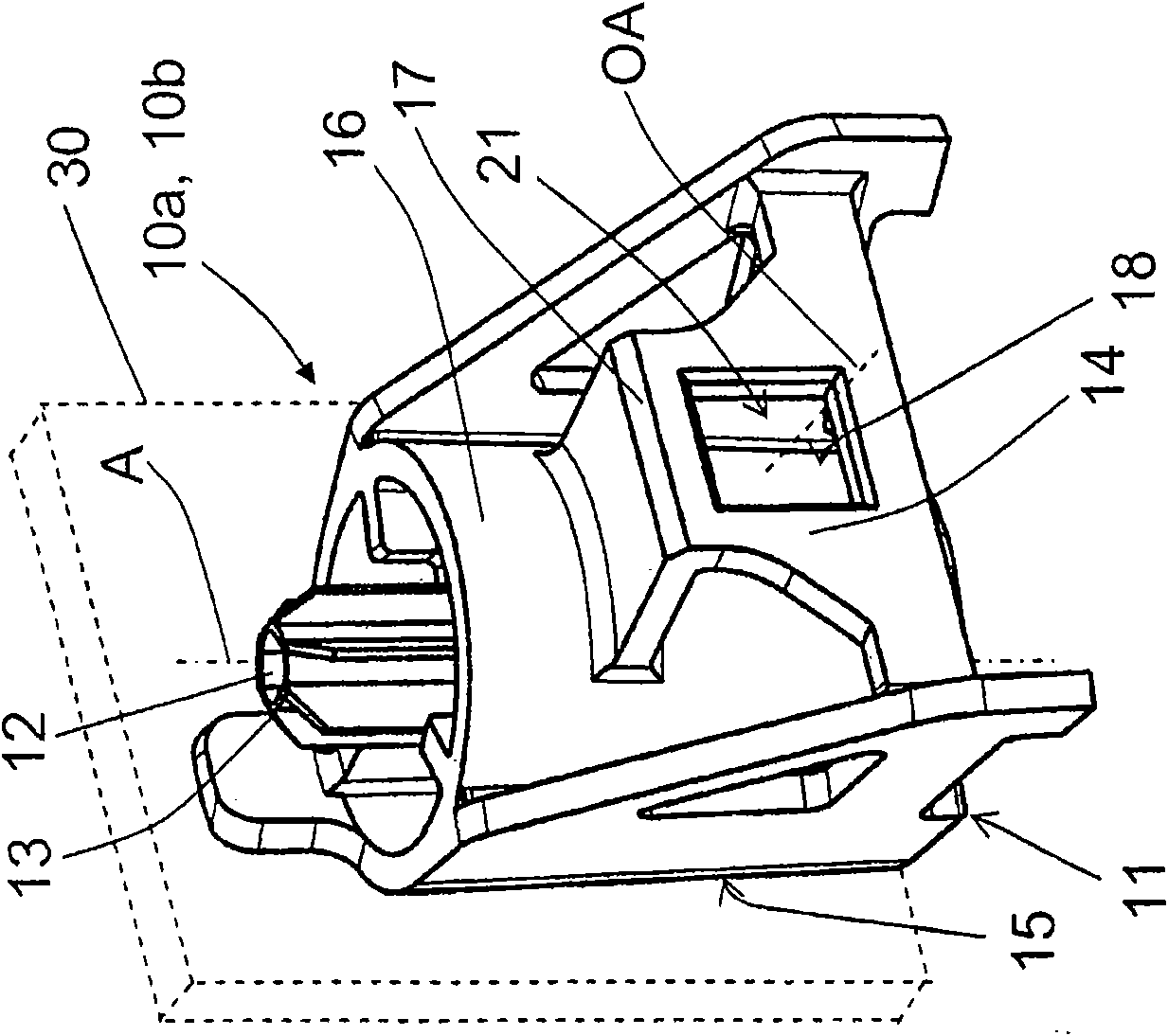

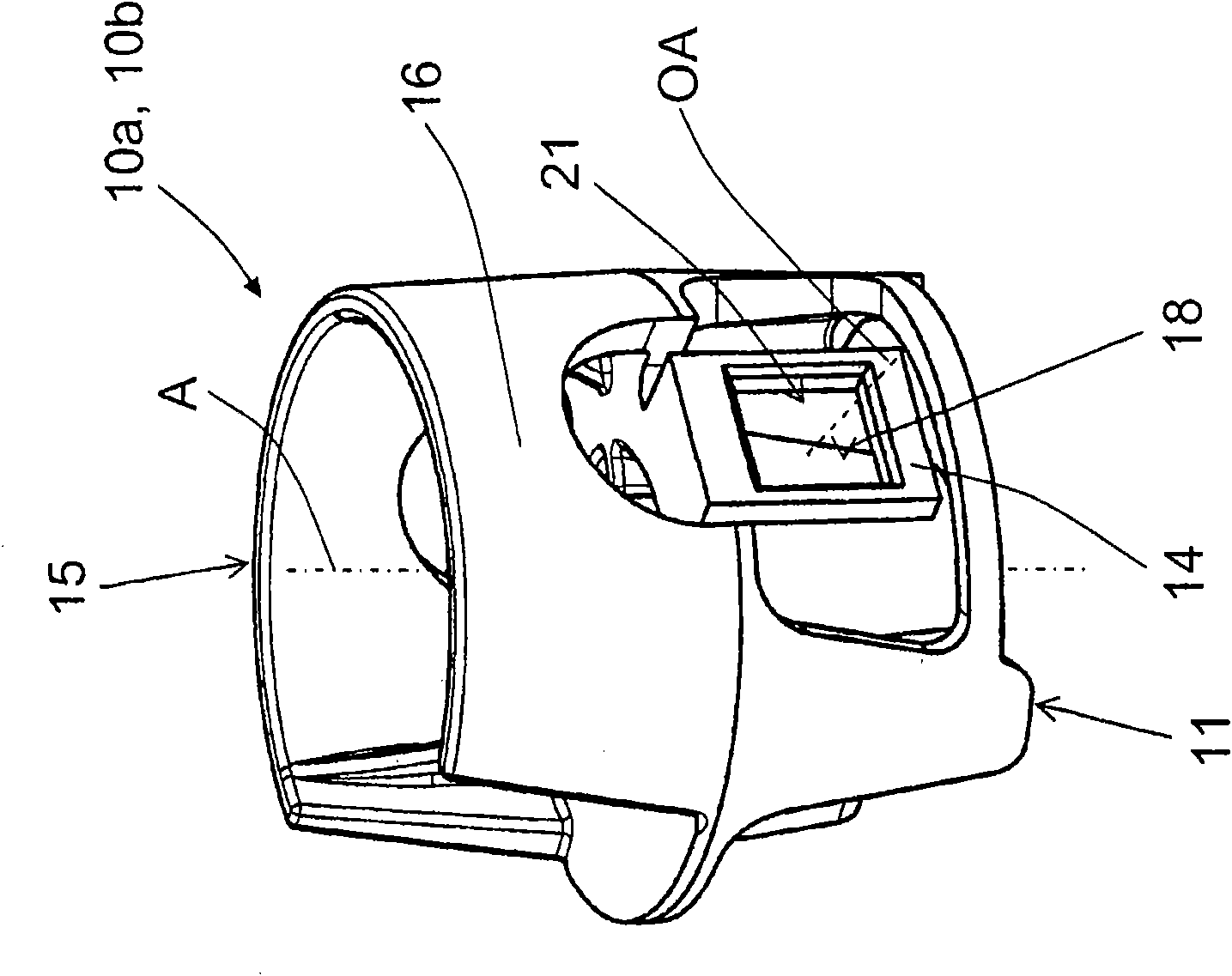

[0024] exist figure 1 with 2a shows the stop body system according to the invention. exist figure 1 2 shows two stop bodies 10 a , 10 b of the stop body system and a spacer element 20 , wherein the first stop body 10 a is fixedly connected to the spacer element 20 via a coupling device to be described in detail. The stop bodies 10a, 10b have a base 11 for mounting on a structural component and a through-hole 12 defining the fixed axis A. As shown in FIG. Around the through hole 12 is formed a seat 13 for the fixing element. In addition, the stop body 10a, 10b also has a peripheral wall 16 and at least one stop surface 15 for the formwork arm 30 (see Figure 2a ), wherein the stop surface 15 can be at least partially formed by the peripheral wall 16 . On the brackets 17 projecting laterally from the peripheral walls 16 of the stop bodies 10a, 10b respectively, a bayonet opening 18 constituting the engagement mechanism 21 is arranged in a wall section 14, wherein the openin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com