Central cross beam connecting type hinging framework

A connected, beam technology, applied in the direction of bogies, railway car body parts, transportation and packaging, etc., to achieve the effect of optimized design, low manufacturing cost, and reduced design difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

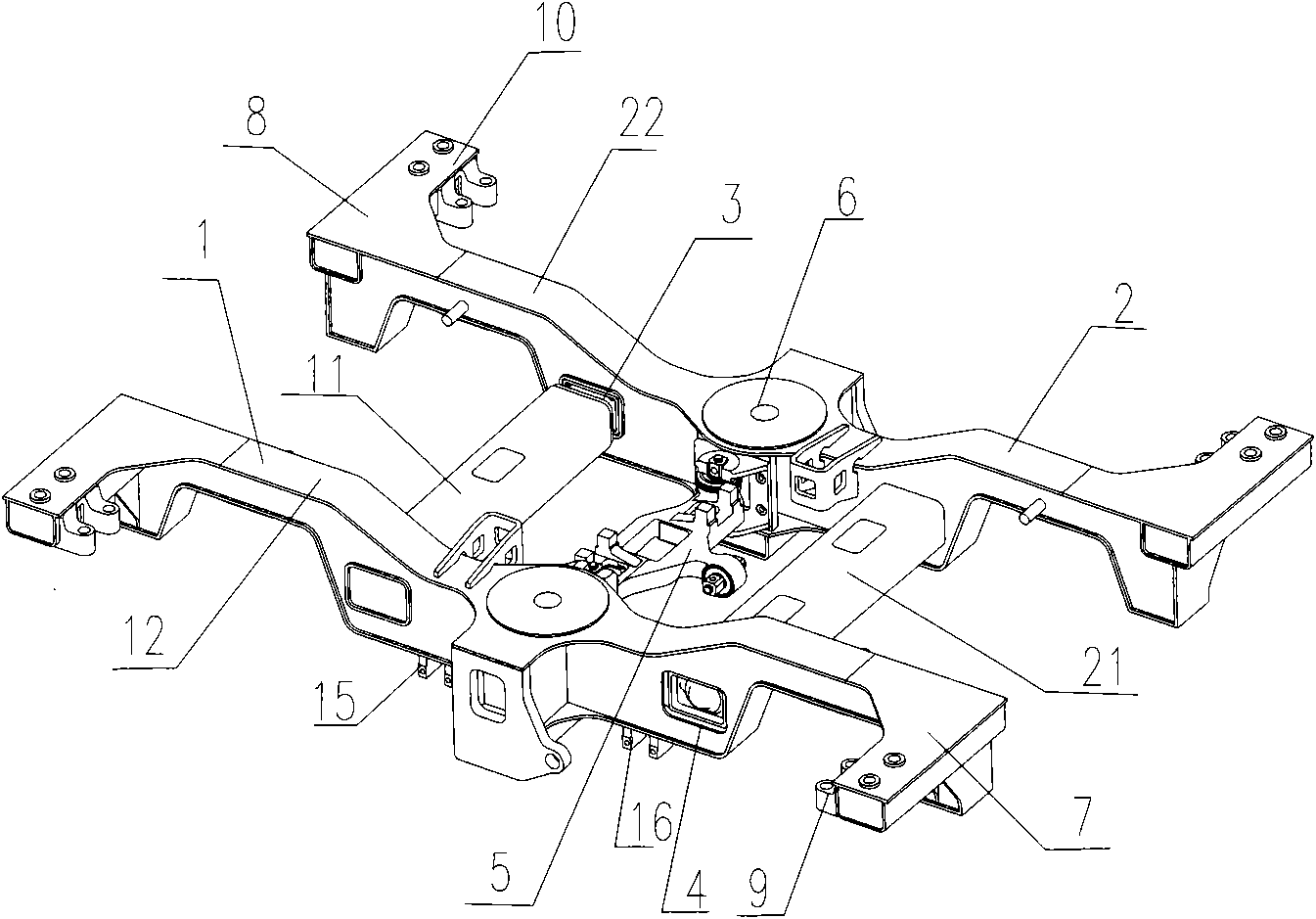

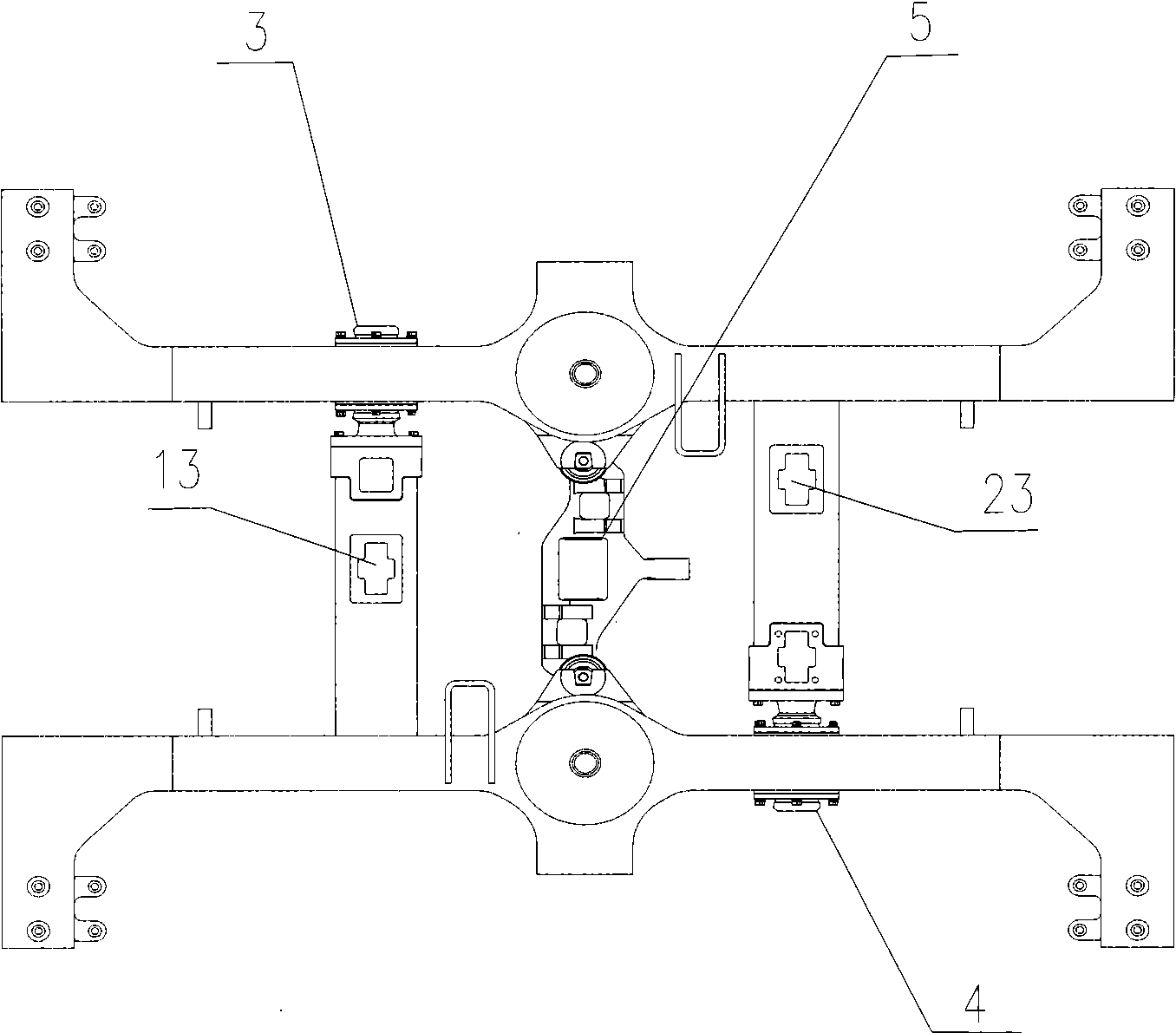

[0022] Example 1, such as figure 1 and figure 2 As shown, the central crossbeam-connected hinged frame includes two T-shaped frames 1 and 2 that are hinged to each other. in,

[0023] The frame 1 has vertically connected and integrally formed cross beams 11 and side beams 12 , and the frame 2 has vertically connected and integrally formed cross beams 21 and side beams 22 .

[0024] The crossbeams 11 run through the sidebeams 22, and are fixedly connected with each other by a bearing-type hinged structure 3. The crossbeams 21 run through the sidebeams 12 and are fixedly connected with each other by a bearing-type hinged structure 4 . The hinge structure 3 and the hinge structure 4 are arranged diagonally on the inner side of the frame.

[0025] The central beam 5 is respectively connected to the side beam 12 and the side beam 22 through elastic nodes at both ends, and the central beam 5 is arranged between the beam 11 and the beam 21 .

[0026] On the crossbeam 11, a moto...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap