Plastic cement combined type pallet

A combined, pallet technology, applied in rigid containers, containers, packaging, etc., can solve the problems of large integrated molds, inconvenient assembly work, large area, etc., and achieves a small number of molds, saving mold and assembly costs and volume. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

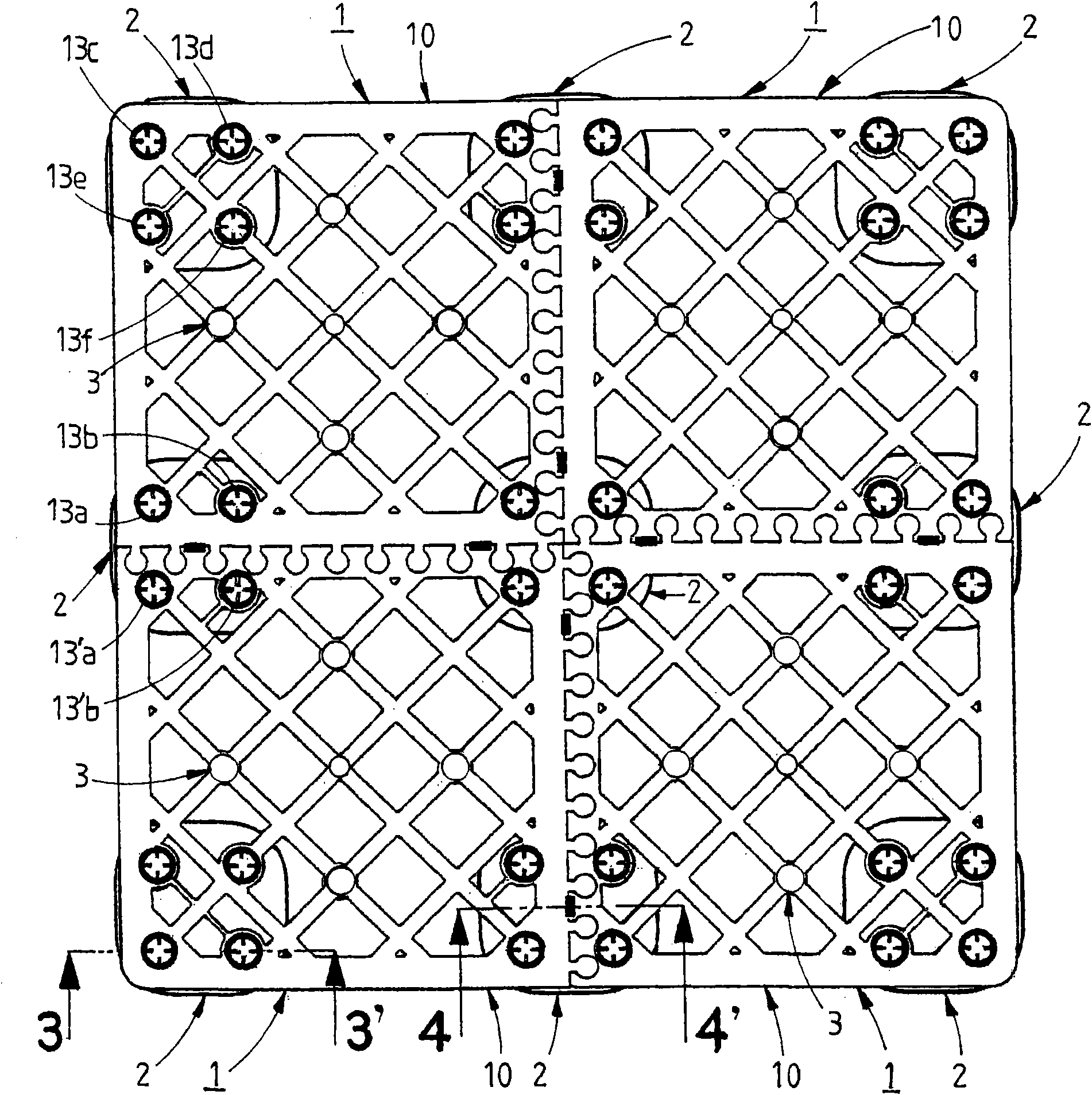

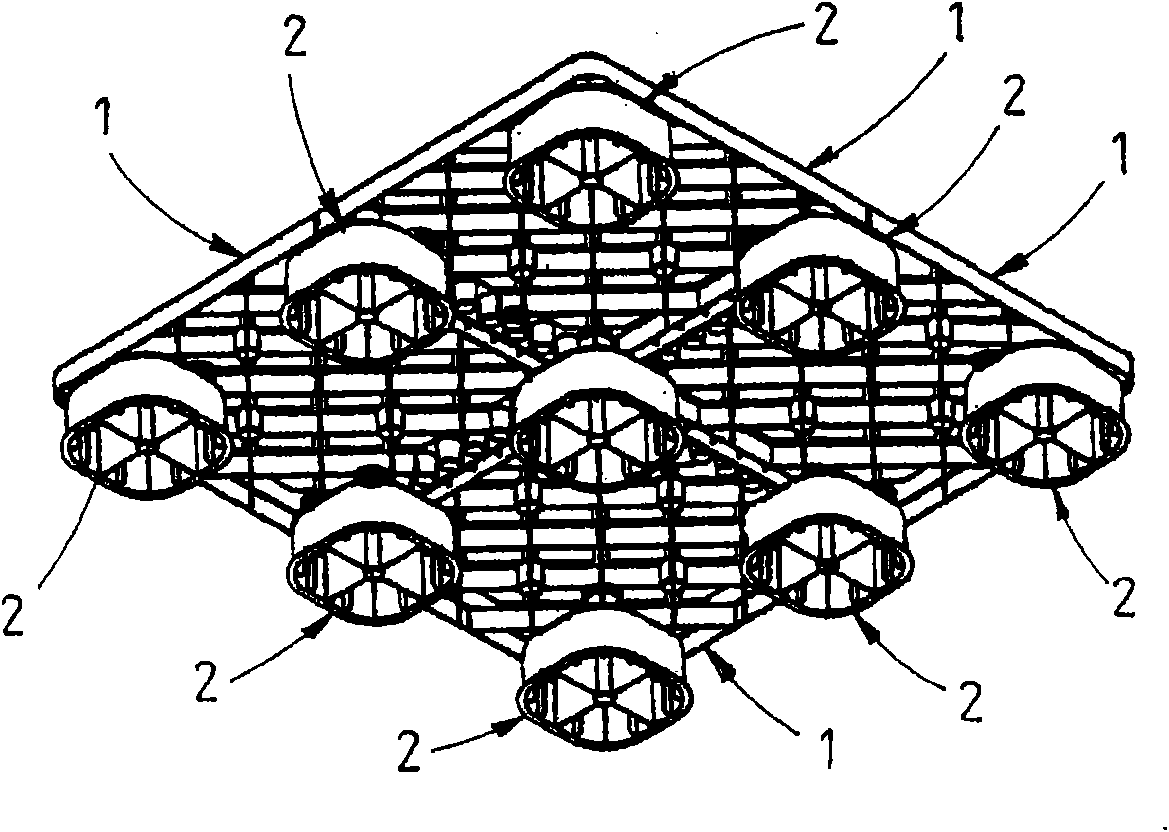

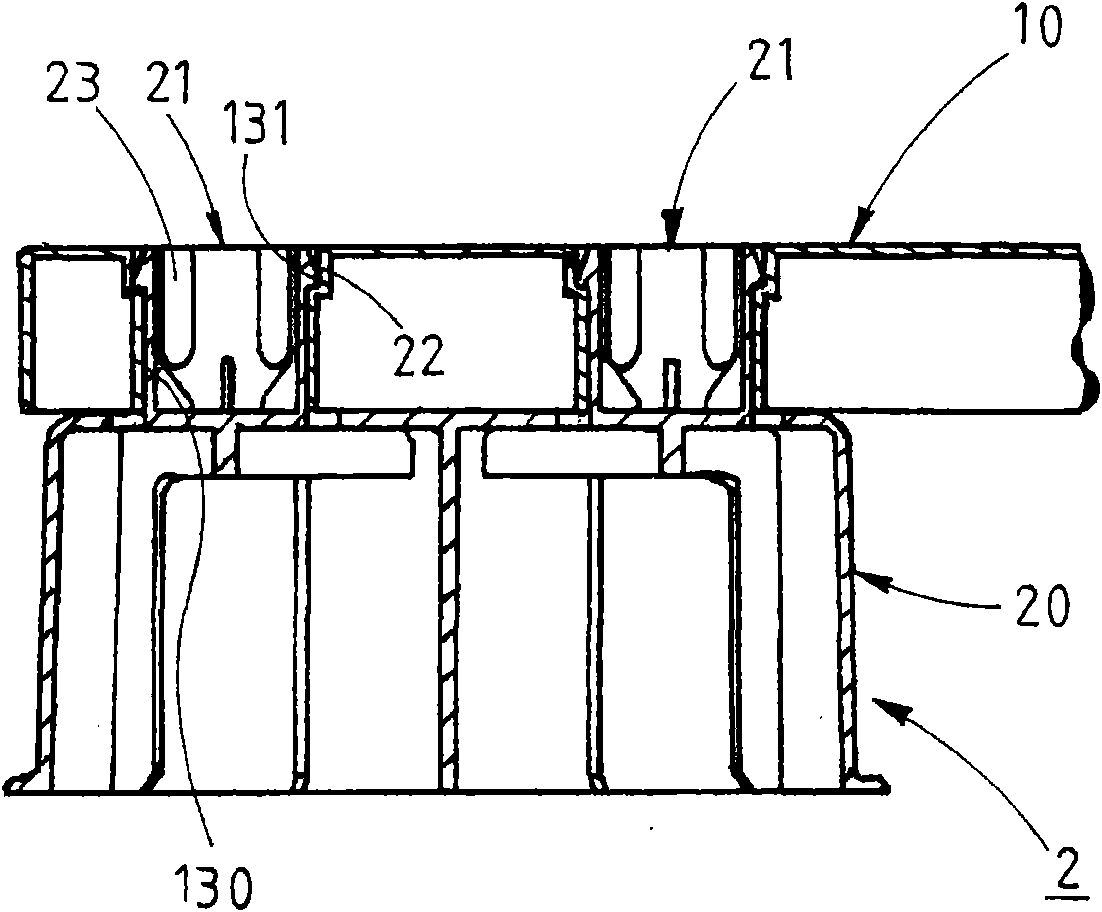

[0043] Please refer to figure 1 , figure 2 As shown, the plastic combined pallet of the present invention includes: four unit panels 1 and nine foot pads 2 devices. Each unit panel 1 is detailed as Figure 5 , Figure 7As shown, its shape, structure and size are all set to be exactly the same, that is to say, it is integrally molded with the same plastic raw material by a pair of molds. They are all set as a square plate body 10, and a plurality of tenons 11 are provided between the extensions on the side edge of the square plate body 10, and on the side edges adjacent to the side edges where the plurality of tenons 11 are arranged, correspondingly set A plurality of tenons and grooves 12 corresponding to the shape of the plurality of tenons 11; at the same time, on the four corners of the square plate body 10, there are: a single fish-eye perforation 13, and two pairs of fish-eye perforations in a group 13a, 13b; 13'a, 13'b and a group of four fish-eye perforations 13c, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com