Vertical shaft type wind power generator

A technology for wind turbines and generators, which is applied to wind turbine components, wind turbines, wind power generation, etc., can solve the problems of low precision of wind turbine speed regulation, complex structure, increased failure rate and maintenance difficulty, etc., to reduce maintenance. The effect of stable workload, power generation output, and improved speed regulation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

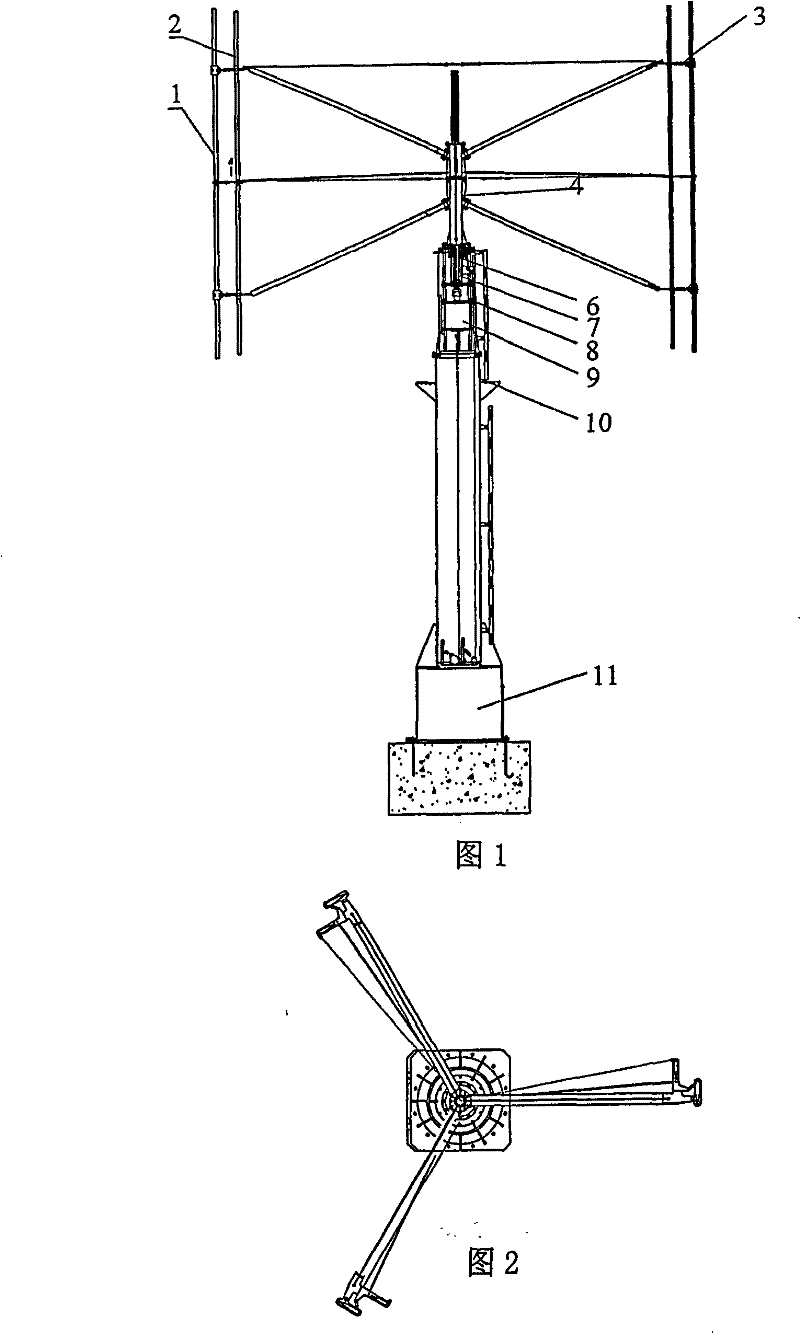

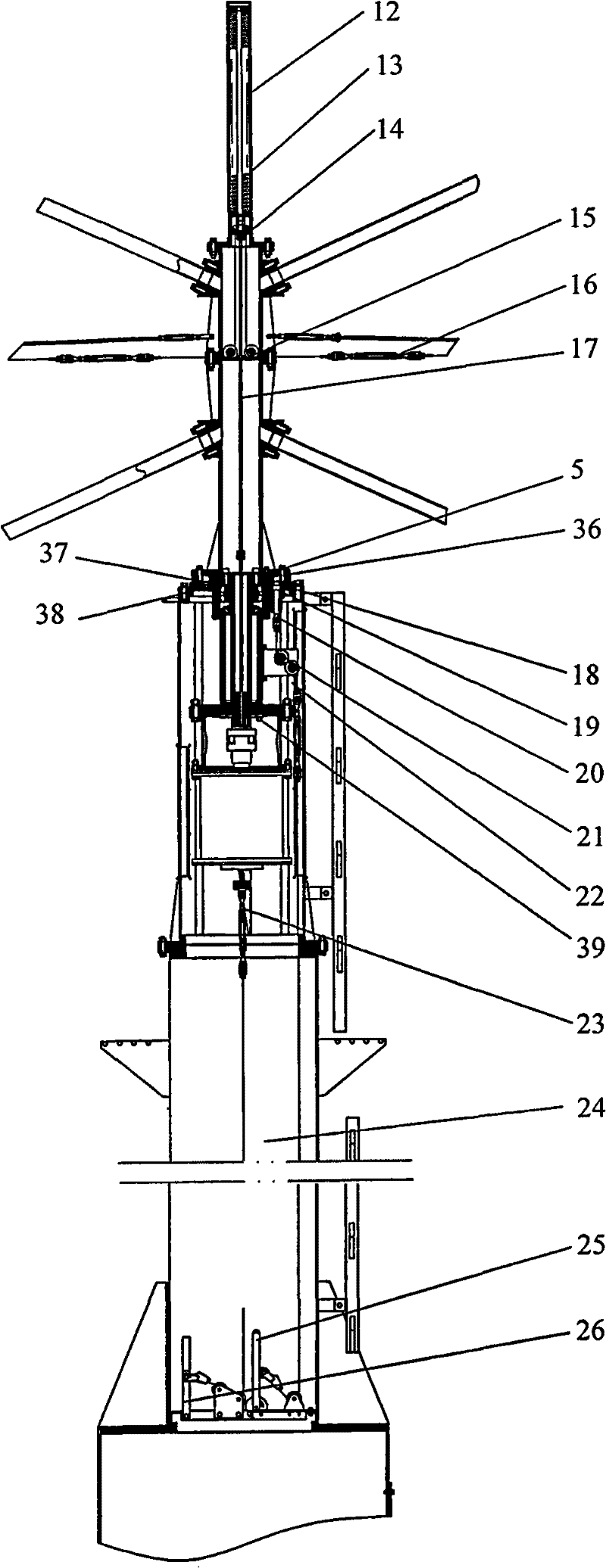

[0032] The specific implementation of the wind power generator of the present invention will be further described below in conjunction with the accompanying drawings.

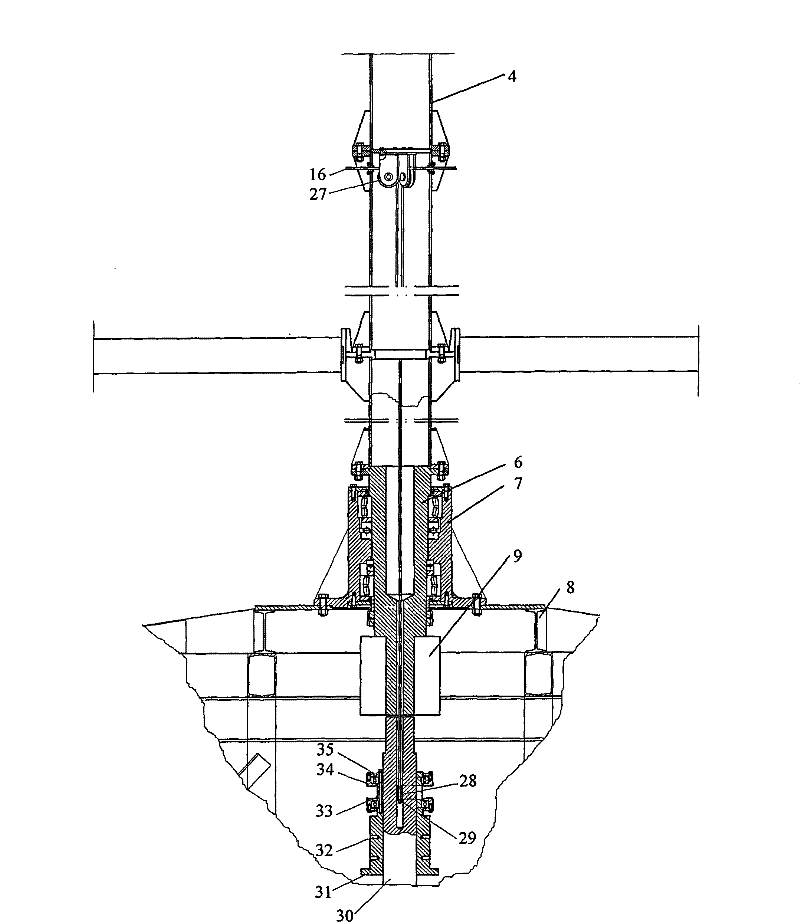

[0033] figure 1 , 2 Shown is the three sets of blade vertical shaft wind power generators of the present invention, its structure includes the wind rotor tower 4 installed with the wind rotor, and the wind turbine base 8 and the tower 10 which are connected with the tower 4 vertically in sequence from top to bottom and base 11. Three groups of blades are arranged at intervals along the horizontal circumference. Each set of blades includes main blades 1 and auxiliary blades 2, and the main and auxiliary blades are connected together through a linkage mechanism 3;

[0034] A speed regulating cable 16 is set between each blade group and the tower column, and a confluence joint 14 and a pulling device are arranged in the tower column. Wherein, the far-center end of each speed-regulating cable 16 is respectivel...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap