Evaluation method of tribology performance of self-lubricating joint bearing

A joint bearing and evaluation method technology, applied in the field of tribology, can solve the problems of incomplete evaluation of tribological performance, inaccurate analysis of friction and wear mechanism, failure to reflect friction and wear mechanism, etc., and achieve accurate wear level and comprehensive tribological performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is further described in conjunction with embodiment.

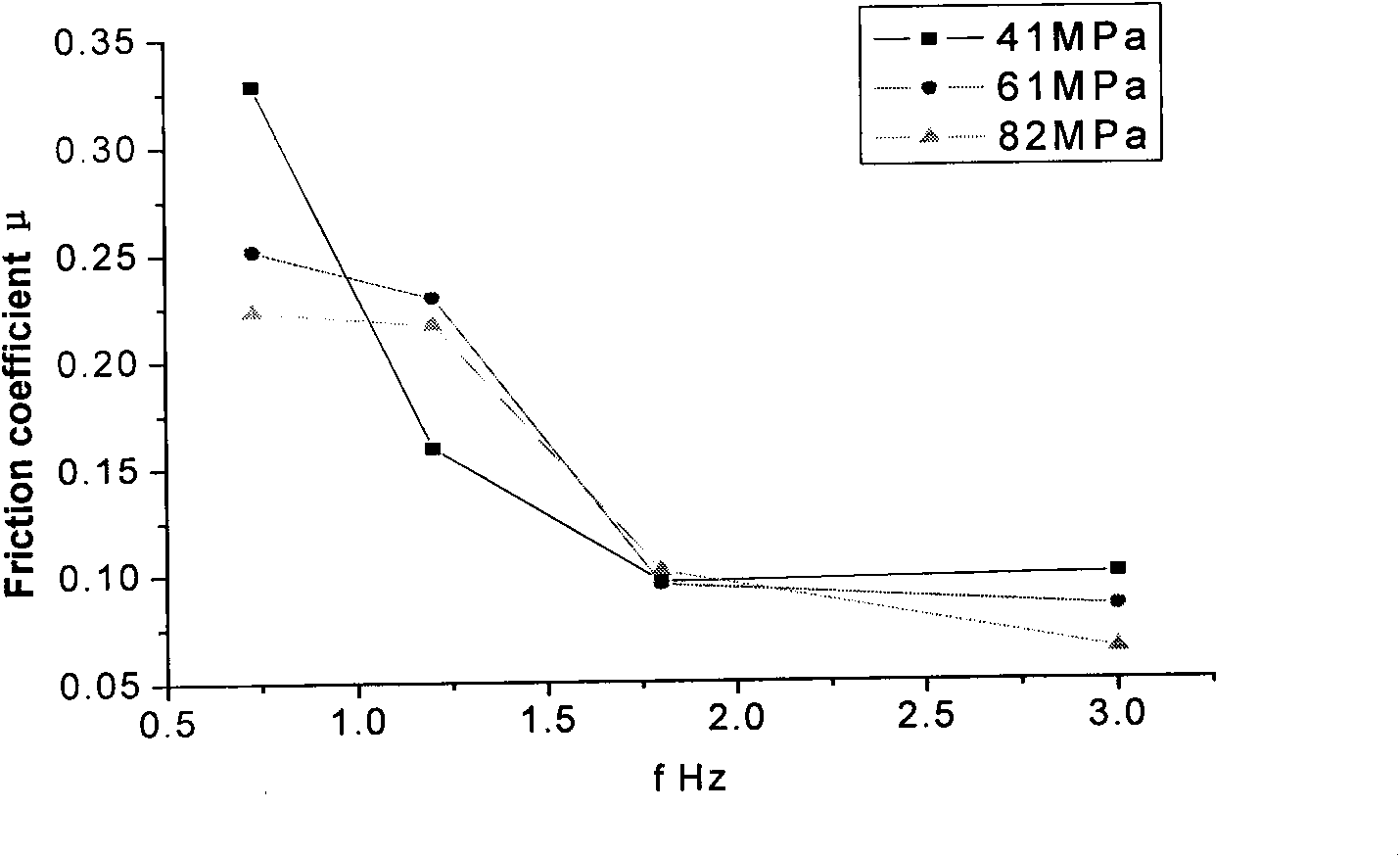

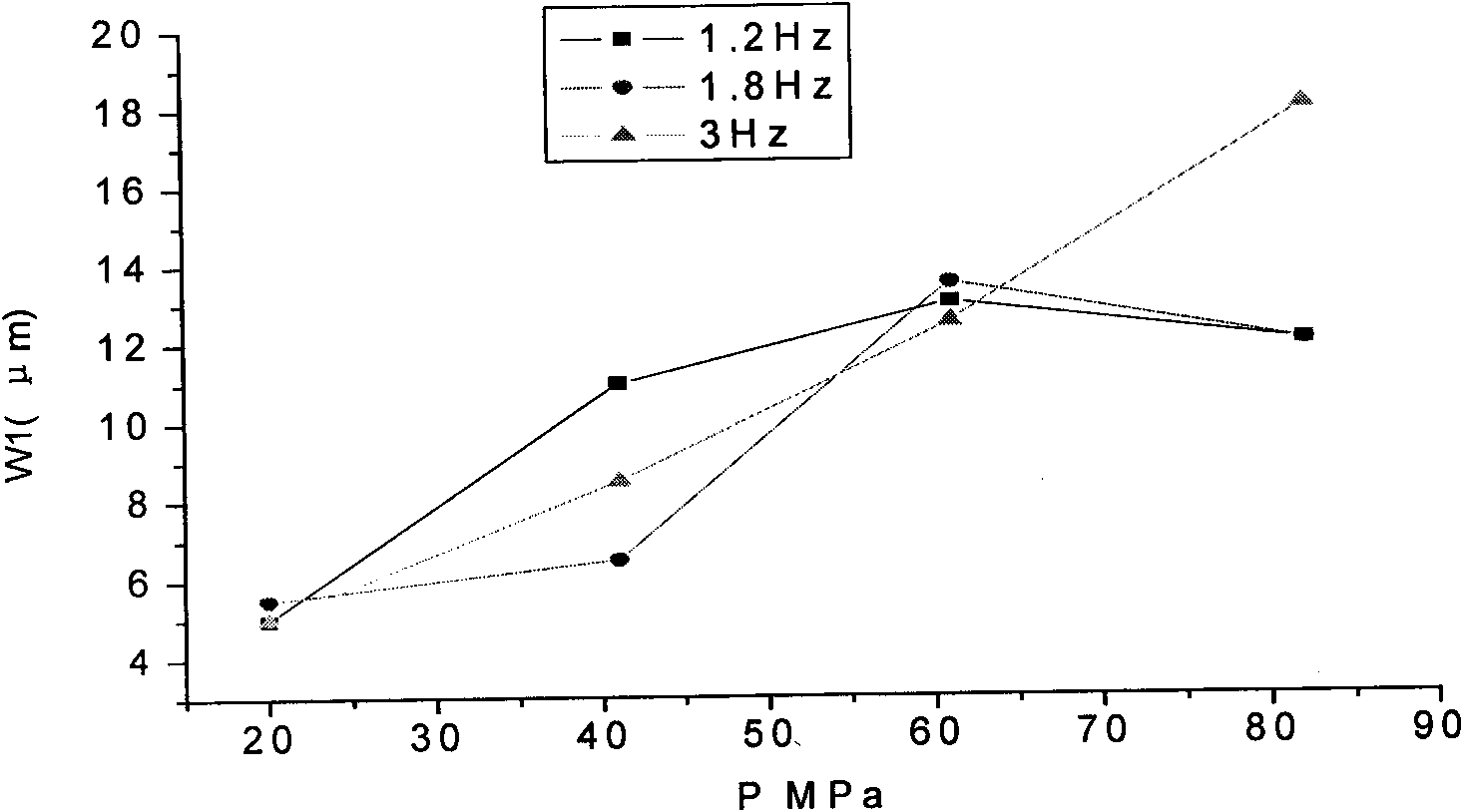

[0019] (1) During the test, the parameters such as the friction coefficient and wear amount of the self-lubricating spherical plain bearing were dynamically monitored under different loads and swing frequencies. After the test, the specific data is analyzed, and the change law of each parameter is analyzed from the curve diagram of the change of each parameter with the load and frequency. For example, the test bearing is a certain type of self-lubricating spherical plain bearing. The inner diameter of the inner ring is 12mm, the width of the inner ring is 10mm, the outer diameter of the outer ring is 25mm, and the width of the outer ring is 7mm. figure 1 with figure 2 They are the relationship curves of the test bearing friction coefficient changing with the swing frequency and the relationship curves of the self-lubricating bearing wire wear amount changing with the normal pressure. It can ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com