Automatic distributing mechanism of connector posts for wire connecting terminal

A technology of distributing mechanism and terminal, which is applied in the field of automatic distributing structure, can solve the problems of easily stuck materials occupying an area, reduce the speed of terminal, increase the auxiliary time, etc., achieve convenient cleaning and maintenance, reduce error rate, structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

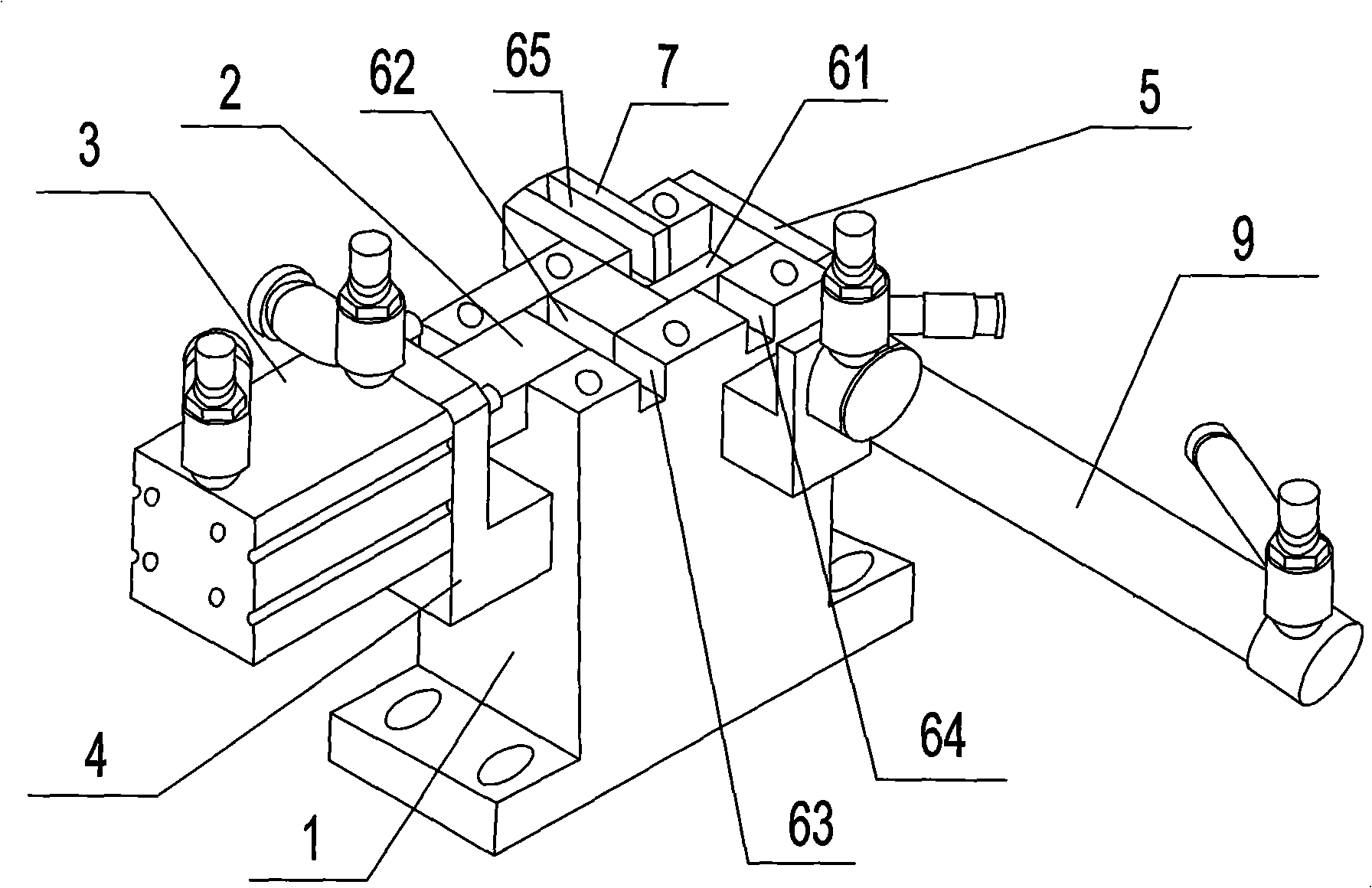

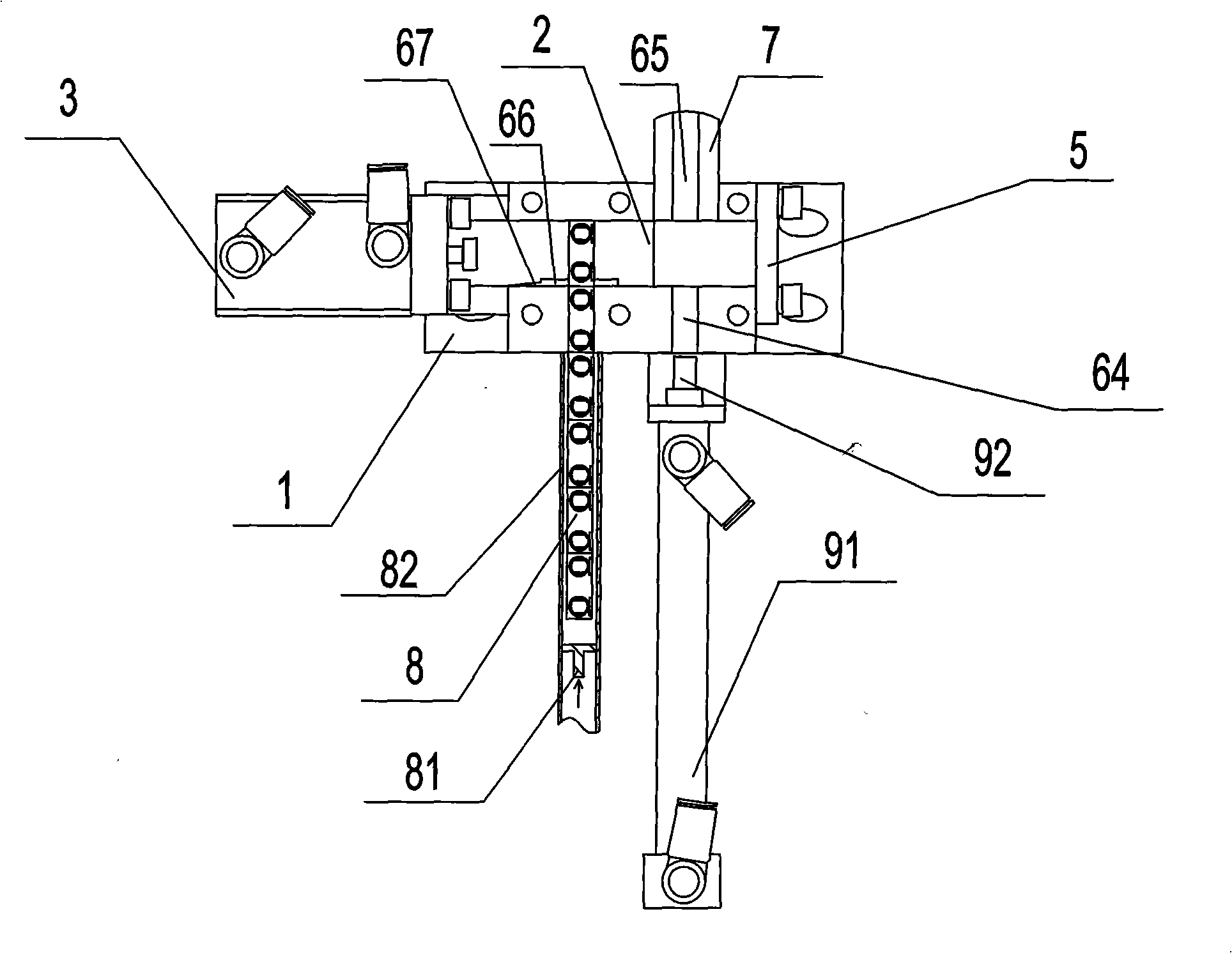

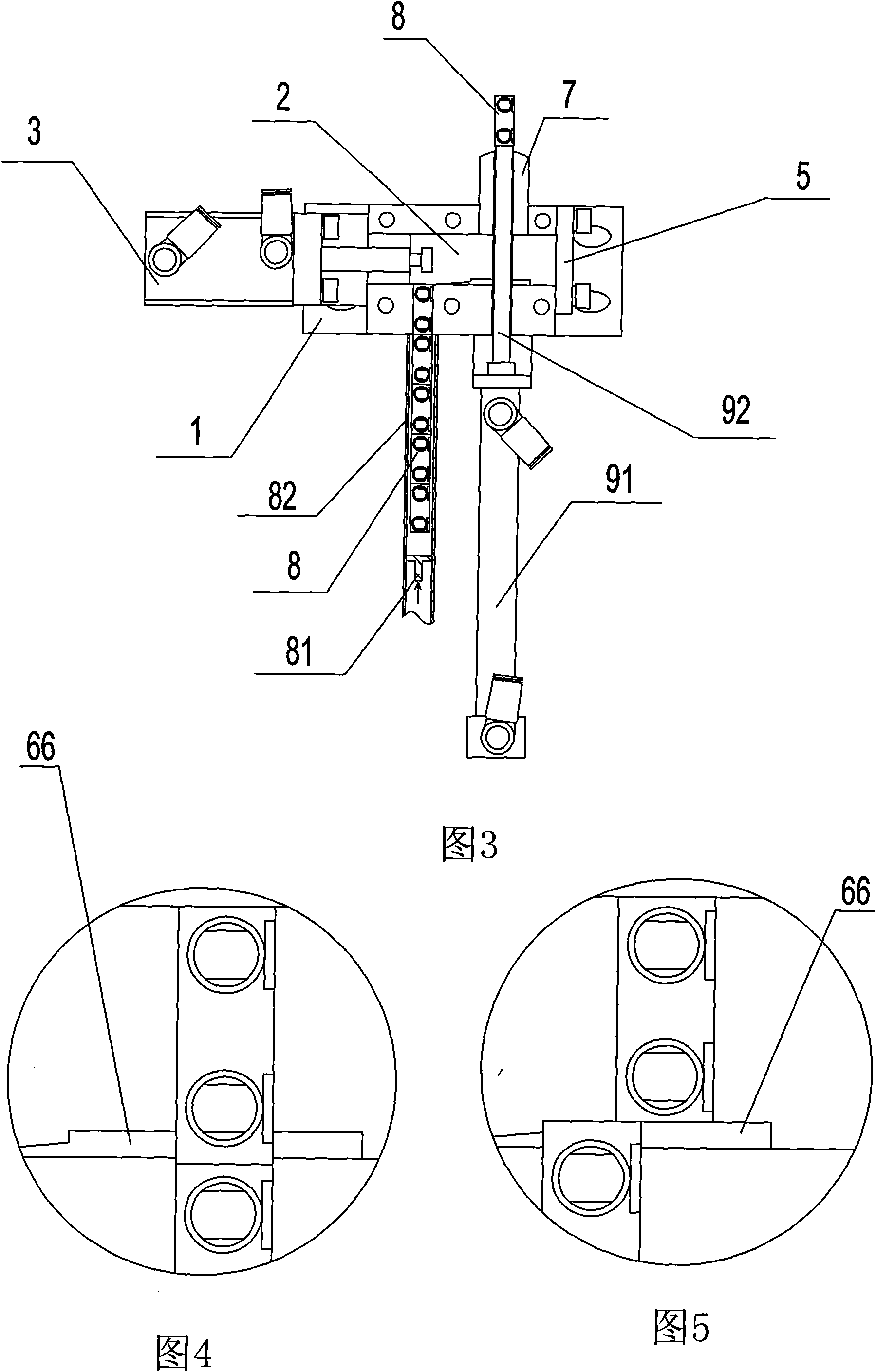

[0024] Such as figure 1 As shown, an automatic distributing mechanism for wiring terminals for wiring terminals is used to screen the entire batch of wiring terminal workpieces 8 to separate individual individuals with qualified lengths and then send them to the next process. Institutions include:

[0025] --Distributing base; along the longitudinal direction of the distributing base 1, there is a transverse groove 61, the width of the transverse groove is the upper limit size of the qualified length of the terminal; the vertical distributing base has a conduction on the longitudinal direction of the distributing base Push chute 63 with transverse groove;

[0026] --Feeding device, which can be movably inserted into the base, includes a guide groove 82 for accommodating a row of terminal posts. The discharge end of the guide groove is correspondingly joined to the pusher groove; the other end of the guide groove is provided with a pusher terminal row Pushing device 81 advancing a...

Embodiment 2

[0034] This embodiment 2 uses different limit devices to limit the movement of the slider on the basis of embodiment 1. The limit device of this embodiment 2 is that the end surface of the pusher cylinder seat facing the slider is used as the slider in the transverse direction. The front limit of the movement in the groove, the side of the distributing base away from the pushing cylinder serves as the rear limit of the sliding block moving in the transverse groove, that is, the transverse groove only leads to one end of the distributing base.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com