Backlight module group

A backlight module and optical film technology, applied in optics, nonlinear optics, instruments, etc., can solve the problems of difficult adhesive residues, adhesive residues, bright spots, adhesive changes, etc., to achieve convenient installation and disassembly, and ensure assembly quality and efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following descriptions of the various embodiments refer to the accompanying drawings to illustrate specific embodiments in which the present invention may be practiced. The directional terms mentioned in the present invention, such as "upper", "lower", "front", "rear", "left", "right", etc., are only referring to the directions of the attached drawings. Therefore, the directional terms used in the following embodiments of the present invention are used for illustration rather than limitation.

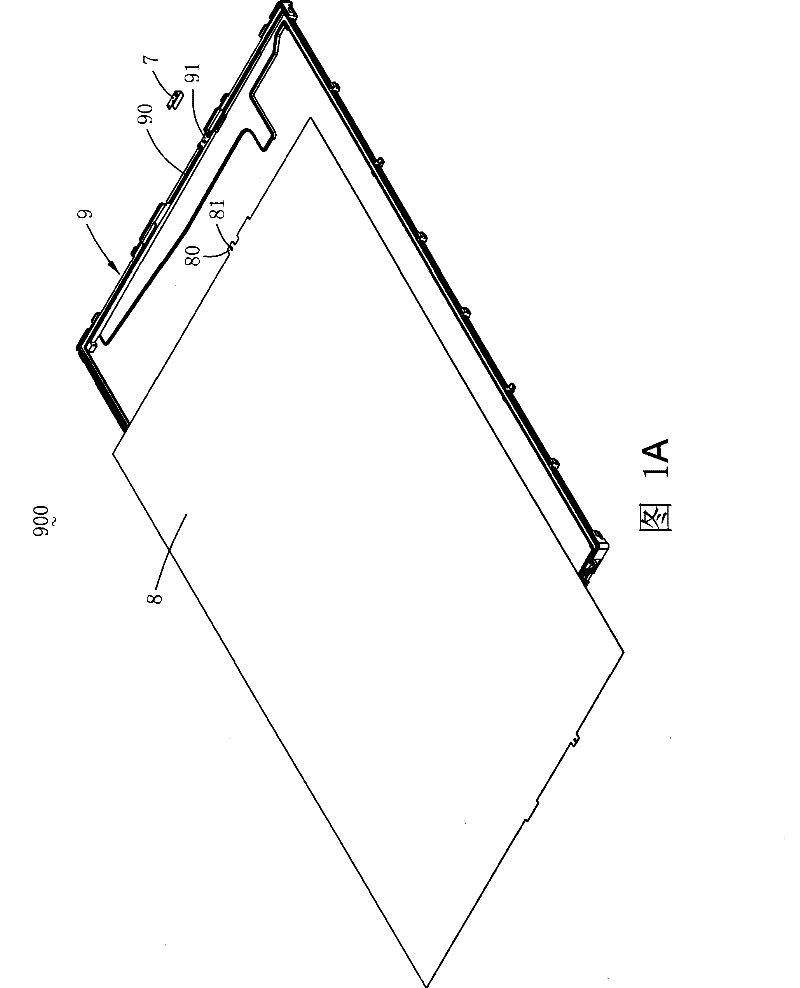

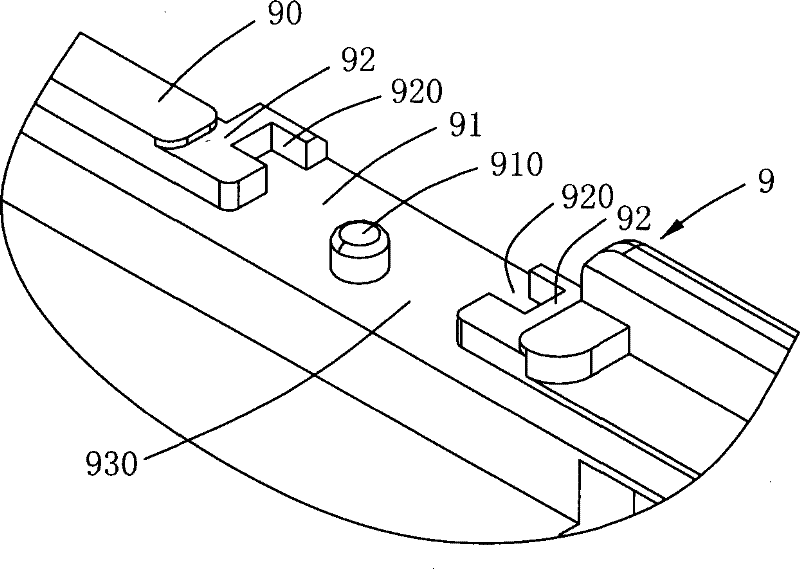

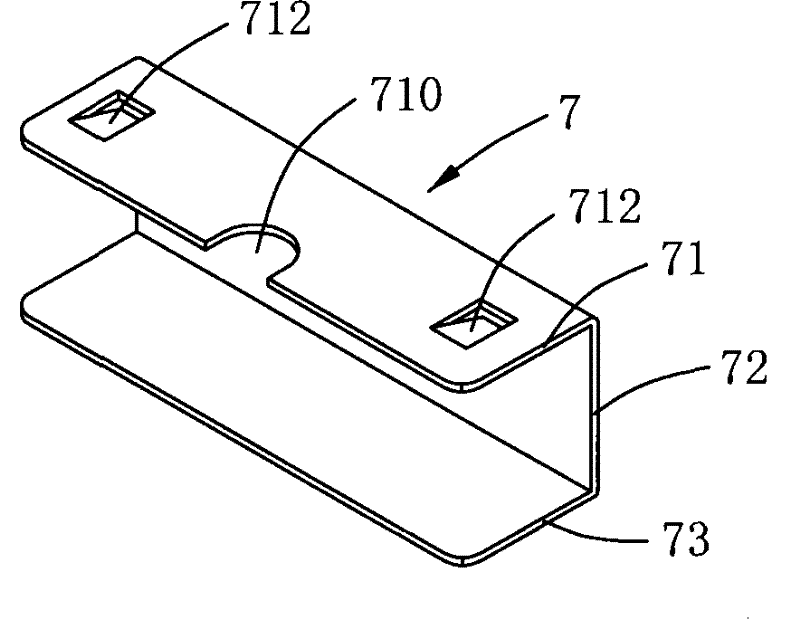

[0031] Please refer to figure 2 , which shows a backlight module 100 according to an embodiment of the present invention. The backlight module 100 in this embodiment includes a plastic frame 1 and at least one optical film 3 , wherein the optical film 3 is arranged and fixed on the plastic frame 1 . In the following, the structure of the plastic frame 1 will be described first, and then the structure of the optical film 3 and its combination with the plastic frame 1 will b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com