Multi-air-chamber self-balancing flat and explosion preventing wheel assembly

A multi-chamber, self-balancing technology, applied in directions with multiple air chambers, rims, vehicle parts, etc., can solve the problems of abnormal leakage, the air chamber cannot be reliably isolated, and the reliability cannot be ensured, and the installation is convenient. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1: Self-balancing anti-leakage and explosion-proof wheel assembly with two air chambers

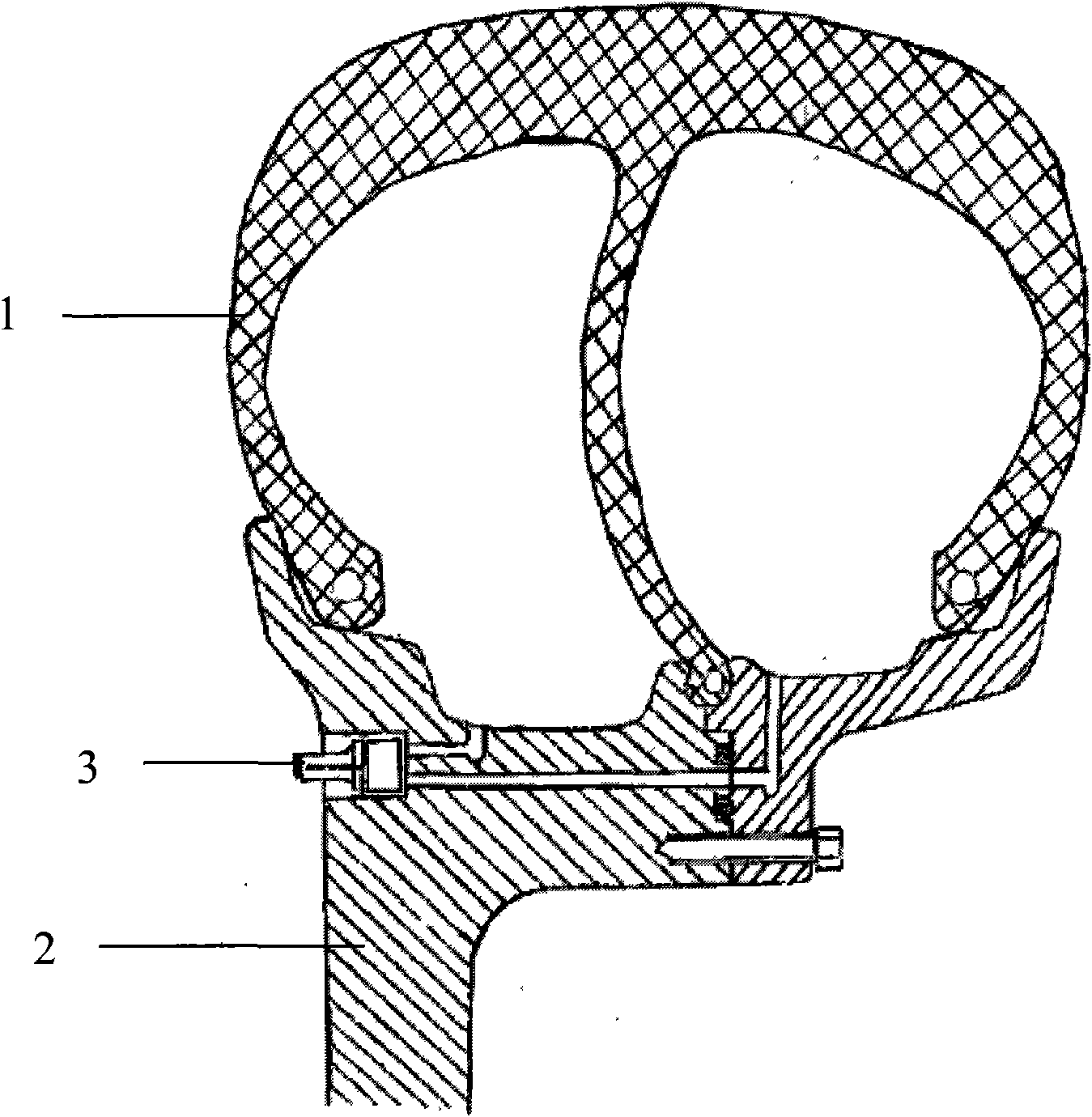

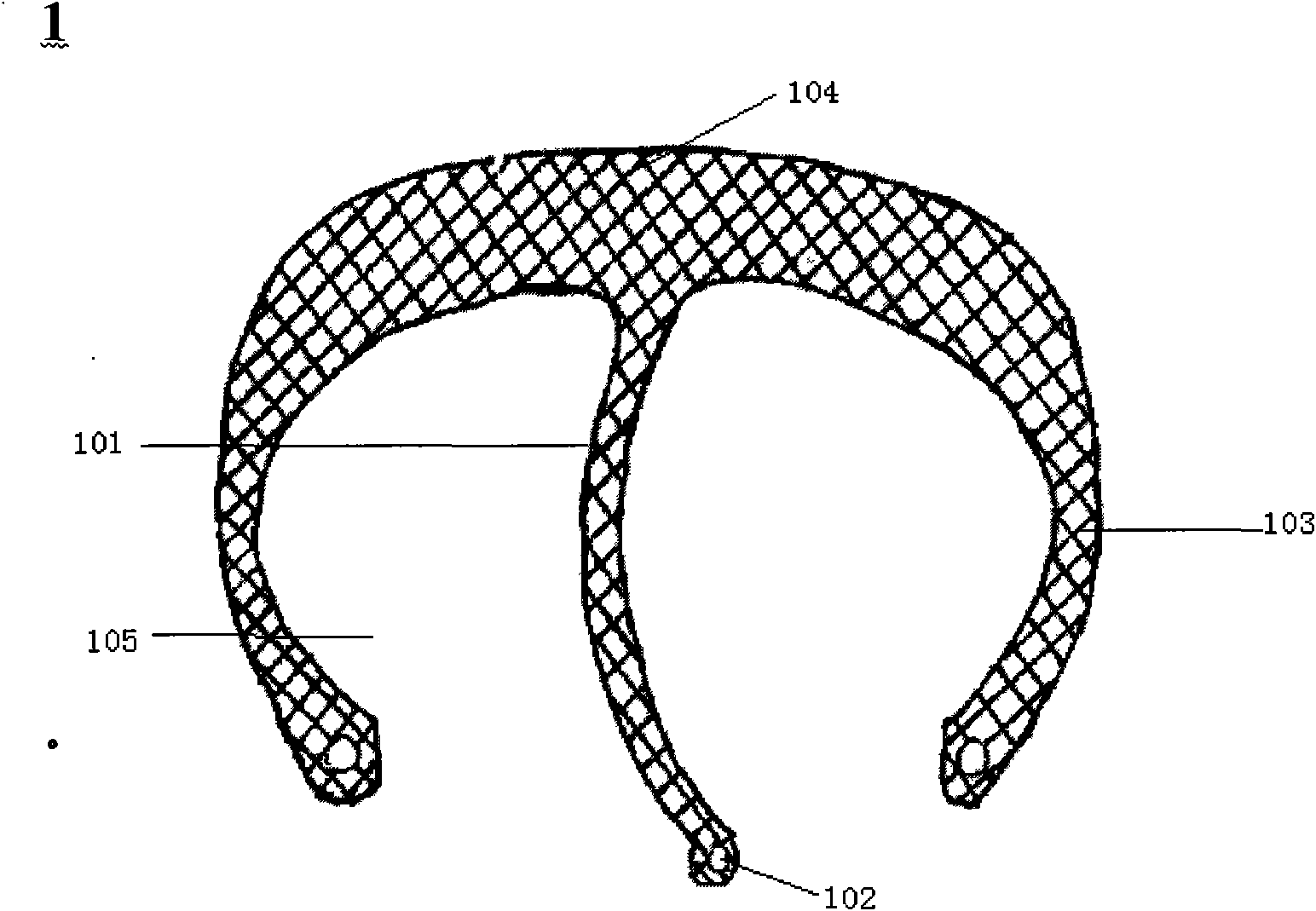

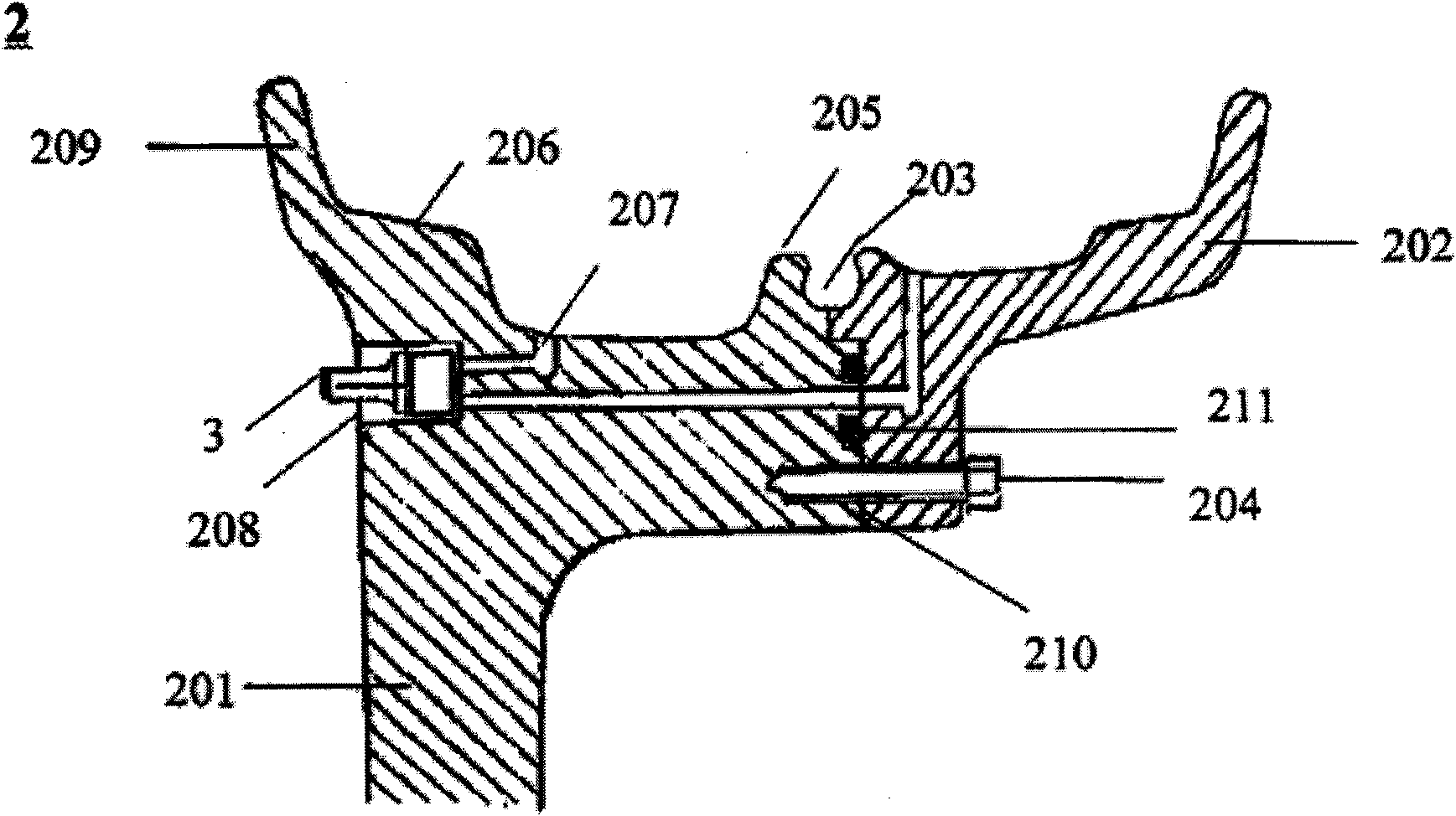

[0028] like figure 1 As shown, the two-chamber self-balancing anti-leakage and explosion-proof wheel assembly includes a tire 1 with two chambers, a two-section clip-on rim 2 and a valve nozzle 3 with two chambers. For a more detailed structure, see figure 2 , 3 , 4. The two-chamber tire 1 forms a two-chamber structure by the spacer ring 101; the two-section clip-on rim 2 includes an outer rim 201 and an inner rim 202, and the outer rim 201 and the inner rim 202 are connected as one by screws 204 and clamped After forming groove 203, the combined position forms middle flange 205, and middle flange 205 and groove 203 all have wheel shoulder; The inner edge thickness of spacer 101 is greater than the width of groove 203, and is clamped in In the groove 203, the valve nozzle 3 includes an outer valve 31 and two inner valves 32, which are connected by pressing and sealing; ...

Embodiment 2

[0034] Example 2: Three-chamber self-balancing anti-leakage and explosion-proof wheel assembly

[0035] Such as Figure 5 As shown, the three-chamber self-balancing anti-leakage and explosion-proof wheel assembly includes a three-chamber tire 1C, a three-section wafer rim 2C and a three-chamber valve nozzle 3C. For details, see Image 6 , 7, 8, The three-chamber tire 1C forms a three-chamber structure by the spacer ring 101C; the three-section clip type rim 2C includes an outer rim 201C and an inner rim 202C, and the outer rim 201C and the inner rim 202C are connected as a whole by screws 204C, Each rim is connected as a whole by screws and clamped to form a groove 203C, and the combined part forms a middle flange 205C; the thickness of the inner edge of the isolation ring 101C is greater than the width of the groove 203C, and is clamped in the groove 203C, The valve nozzle 3C includes an outer valve 31C and two inner valves 32C, the outer valve 31C and the inner valve 32C ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com