Liquid metal infiltration visibility control method and special device thereof

A liquid metal and control method technology, which is applied in the direction of electrical program control, sequence/logic controller program control, etc., can solve the problems that the direct observation and online control of the liquid metal infiltration process cannot be realized.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

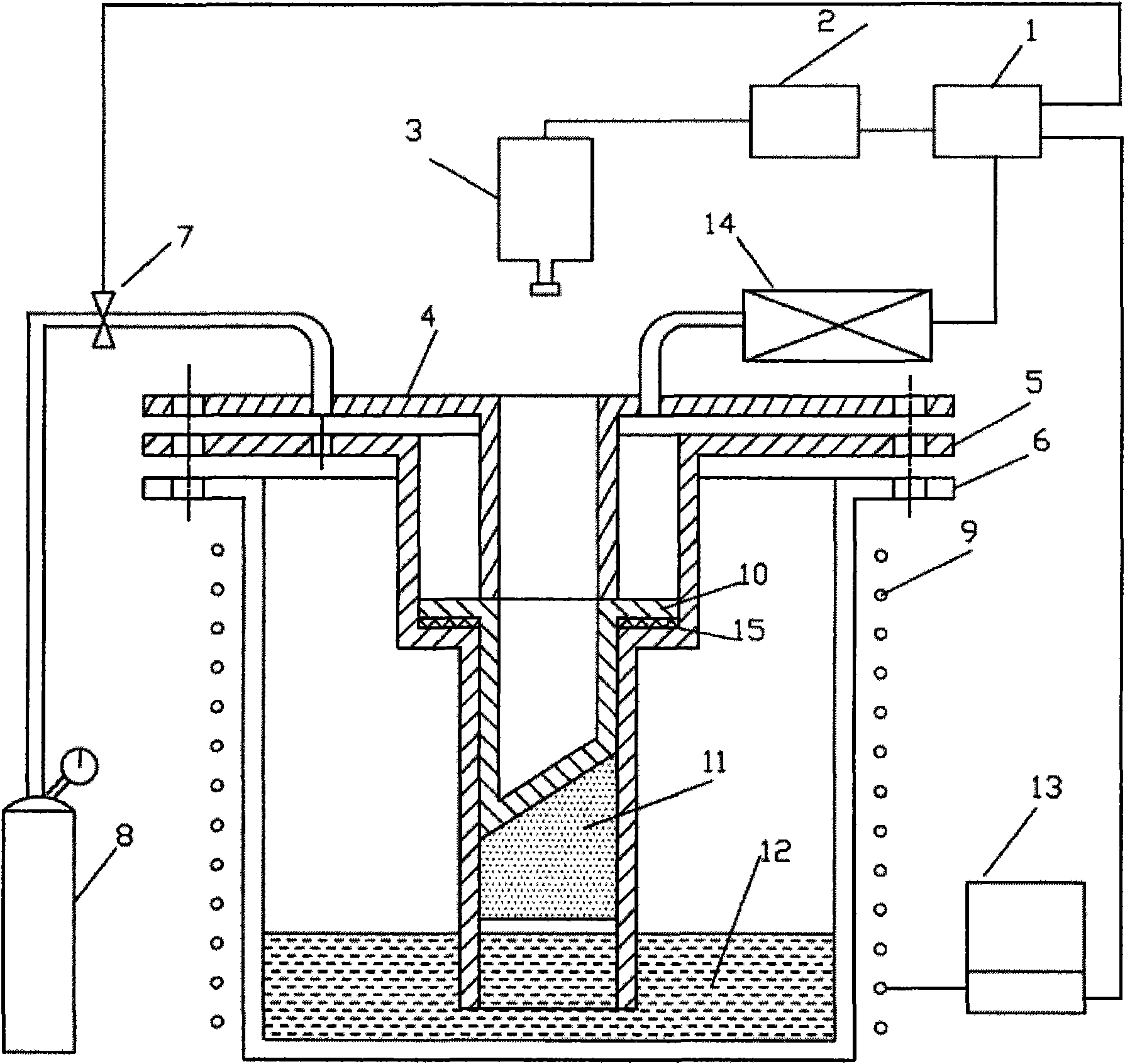

[0020] Embodiment 1: refer to figure 1 , a special device for visualization of liquid metal infiltration in porous media. The device is composed of: an impregnation control system 1 , an image acquisition and processing system 2 , an infrared thermal imager 3 , a temperature controller 13 , and a vacuum pumping system 14 . The infiltration system consists of the infiltration chamber cover 4 , the infiltration chamber 5 , the stainless steel crucible 6 and the sleeve 10 . Eight bolt holes are evenly distributed on the flanges of the infiltration chamber cover 4, the infiltration chamber 5 and the stainless steel crucible 6, and the three are connected by bolts. The seepage chamber cover 4 needs to press the sleeve 10 tightly, and the boss of the seepage chamber cover 4 has a through hole with the same size as the sleeve 10, so as to observe the temperature field information of the sleeve slope, wherein the bottom surface of the sleeve 10 is in the shape of a slope, The slope...

Embodiment 2

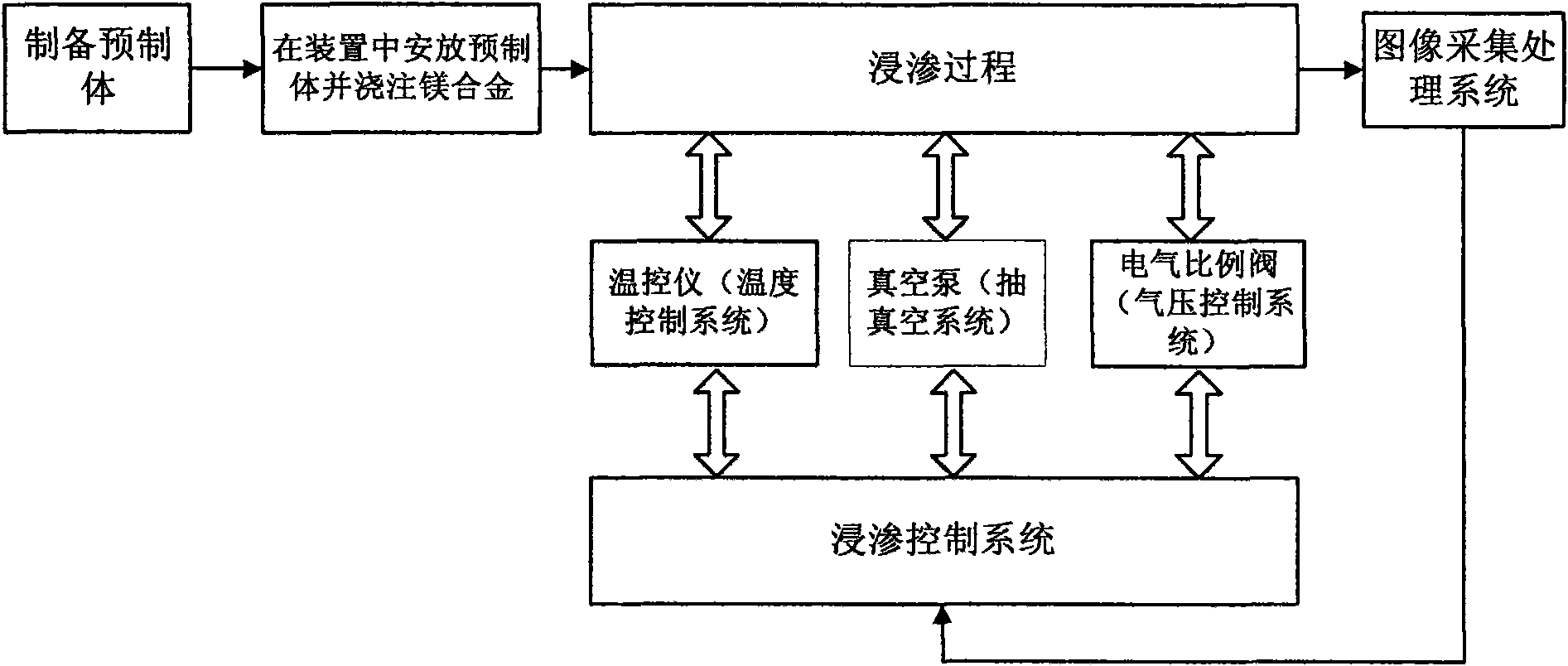

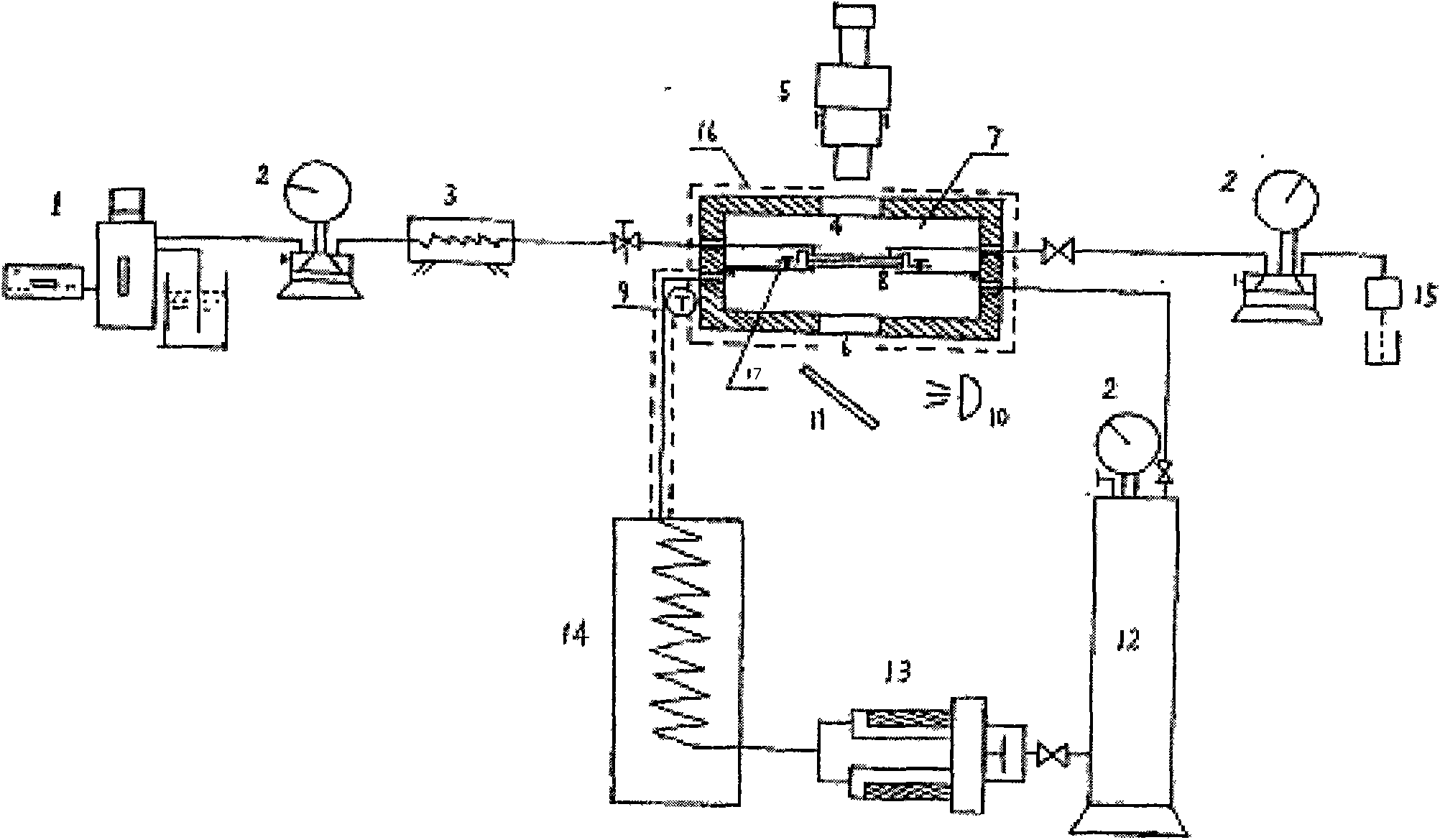

[0023] Embodiment 2: refer to figure 2 , Infrared thermal imager adopts Infortek VarioCAM hr head480 during the implementation of the method of the present invention, the base metal used is AZ91D magnesium alloy, and the prefabricated body is produced by Luoyang Refractory Research Institute. 2 o 3 Made of short fibers. Visualization method for liquid metal infiltration in porous media:

[0024] 1) Put the prepared slope preform into the impregnation chamber 5, put the AZ91D magnesium alloy into the stainless steel crucible 6, and seal the device;

[0025] 2) Start the temperature control system to heat for 1 hour, so that the temperature of the stainless steel crucible reaches 820±5°C, all the magnesium alloy is melted, and keep warm for 30-40 minutes;

[0026] 3) Start the vacuum system, use a vacuum pump to vacuum the inside of the seepage cavity, and stop vacuuming when the vacuum reaches 0.095MPa;

[0027] 4) Start the infrared thermal imager, transmit the digital si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com