Transparent veil with evenly dispersed LED pixel points

A light-transmitting mask and uniform diffusion technology, applied in the field of LED screens, can solve problems such as poor mechanical properties and achieve the effect of eliminating glare

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

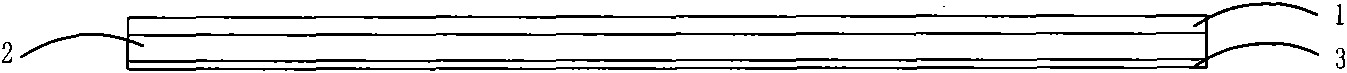

[0037] figure 1 Show the basic structure of the light-transmitting mask that the LED pixel point of the present invention evenly diffuses, as figure 1 The light transmissive visor shown includes:

[0038] The mask body 1 located at the uppermost end is used to transmit the light emitted by the LED and act as the ground of the stage;

[0039] The grid body 2 located under the mask body 1 is used to guide the light emitted by the LED into the mask body 1, and helps to weaken the black band between each pixel on the mask; and

[0040] The circuit board 3 on which a plurality of LED light-emitting elements are mounted under the grid body 3, wherein each LED is higher than the substrate of the circuit board, so that each LED can enter the corresponding space 23 of the grid body 3 middle.

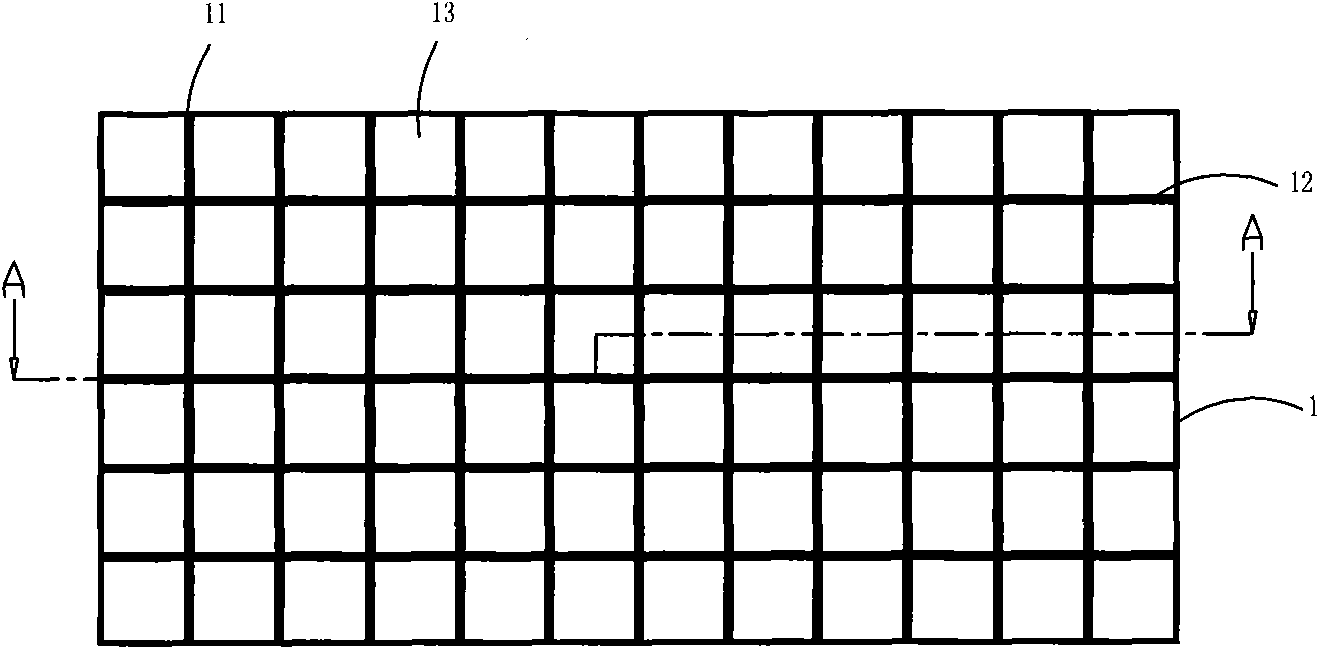

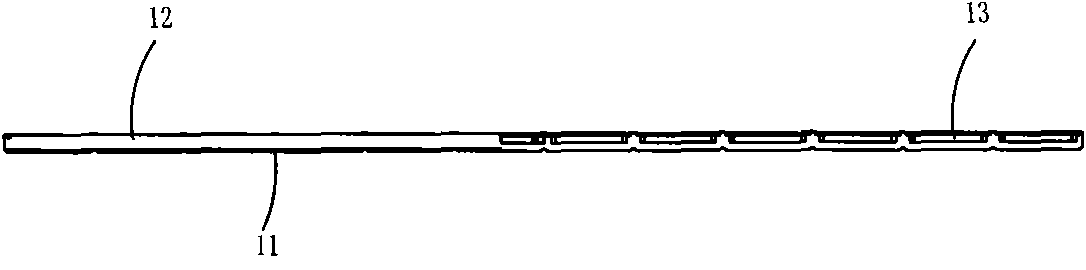

[0041] figure 2 and image 3 The structure of the mask body 1 of the present invention is shown. Such as figure 2 As shown, the mask body 1 is gray, and a plurality of mask units 13 sepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com