Stacked ring type shear apparatus and method for testing composite liner material by same

A technology of cushioning materials and shearing instruments, which is applied in the direction of applying stable shear force to test the strength of materials, can solve the problems of unsuitable size effects for various geotechnical materials tests, single test interface, etc., and achieve large sample size , the effect of reducing the error of the instrument

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

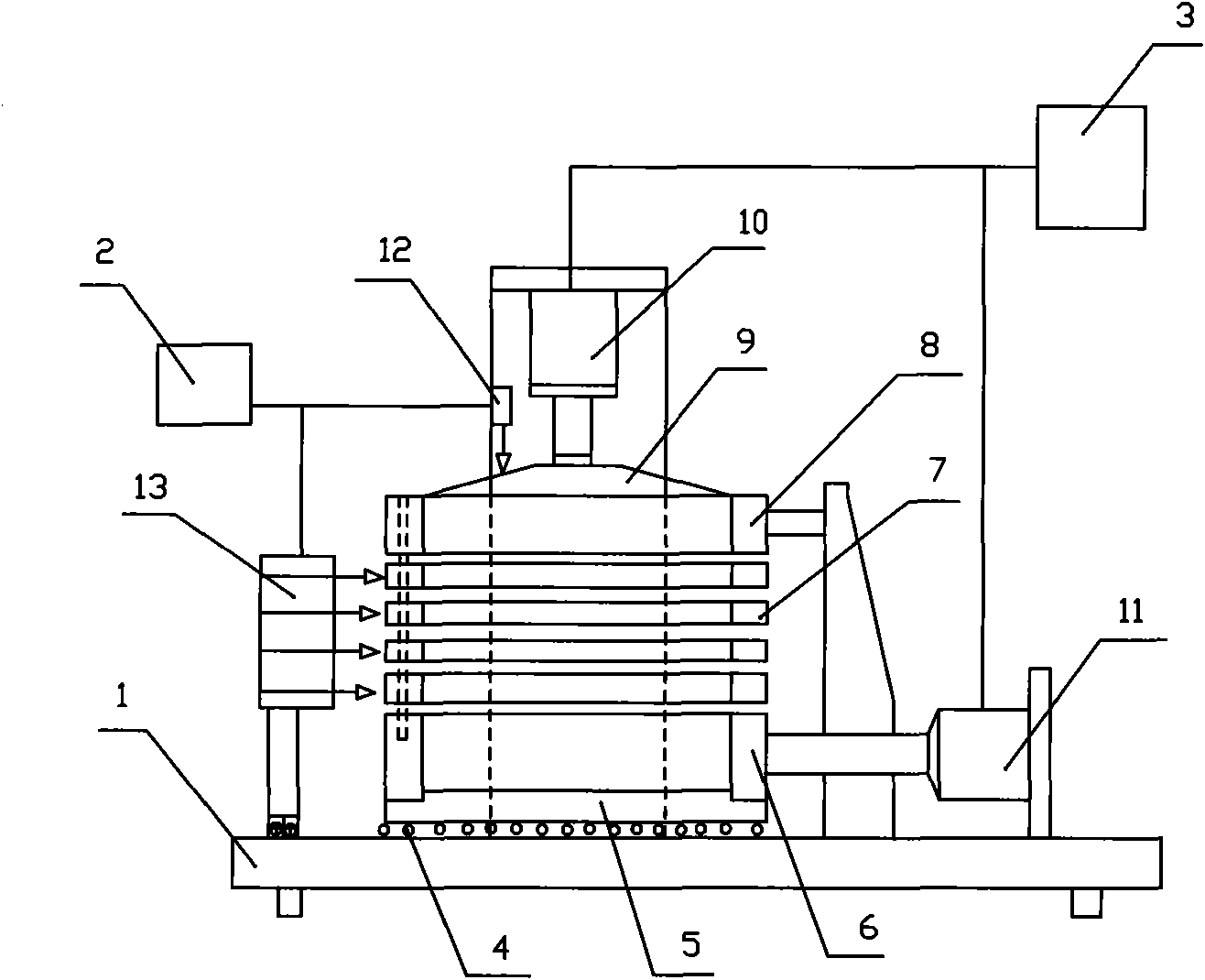

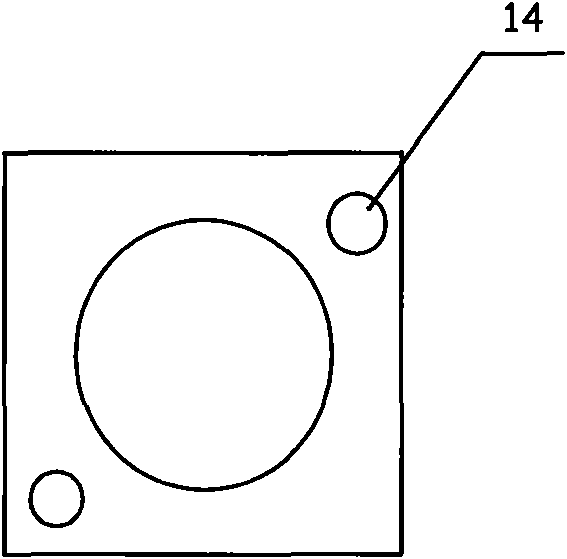

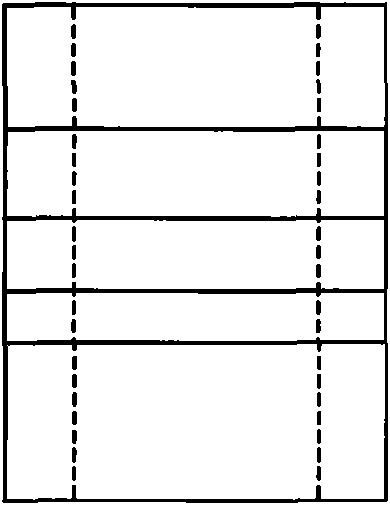

[0024] The material of the conventional compacted clay liner system was subjected to bulk shear tests using two stacked rings, one for the clay geotextile and one for the geomembrane. The geotextile and the geomembrane are respectively glued to the 1.5mm thick lamination ring in the lamination ring group 7; the sand is placed in the lower shear box 6, and the shear lamination ring glued with the geotextile is placed on the sand. A geonet is placed on it, and the shearing ring that is glued with the geomembrane is placed on the geonet, and finally the compacted clay is loaded into the upper shear box 8 . Connect the hydraulic connecting rod of the horizontal hydraulic cylinder 11 with the lower shear box 6, and tighten the bolts; install the horizontal displacement sensor 13, and align it with the stack ring in the stack ring group 7, and install the vertical displacement sensor 12 , make it contact with the cover plate 9, and check whether the sensor is sensitive; connect the ...

Embodiment 2

[0027] If the direct shear test is carried out, it is not necessary to use the stacked ring, and the stacked ring is replaced with an integral upper shear box for direct shearing. Take the direct shearing of the interface between geonet and geomembrane as an example: because the lower shear box 6 is 120 mm thick, it is impossible to directly stick the geomembrane, so a rigid iron block is added in the lower shear box 6 as a support, and then put on the rigid iron block. A rigid plate, the geomembrane is fixedly glued to the rigid plate; the geonet is glued to another rigid plate, placed in the upper shear box 8, so that the geonet and the geomembrane are in close contact.

Embodiment 3

[0029]Combined interface single shear test, taking the combination of geonet, geotextile and sand as an example, the geonet is glued to the rigid plate and placed in the lower shear box 6, and a rigid iron block is added to support the rigid plate in the lower shear box 6 , the geotextile is glued to the shearing ring with 502 glue (because the geotextile itself is only a few millimeters thick, a 1.5mm stacking ring is used at this time), placed on the geonet, and the sand is filled on the geotextile In the stack ring with a thickness of 20mm in the stack ring group 7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com