Composite and assembly construction of engine valve oil seal and valve spring retainer

A technology of engine valves and valve springs, which is applied in the direction of engine components, machines/engines, valve devices, etc., can solve problems affecting engine performance, etc., and achieve the effects of reducing production cycle, improving shock absorption effect, and reducing the number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

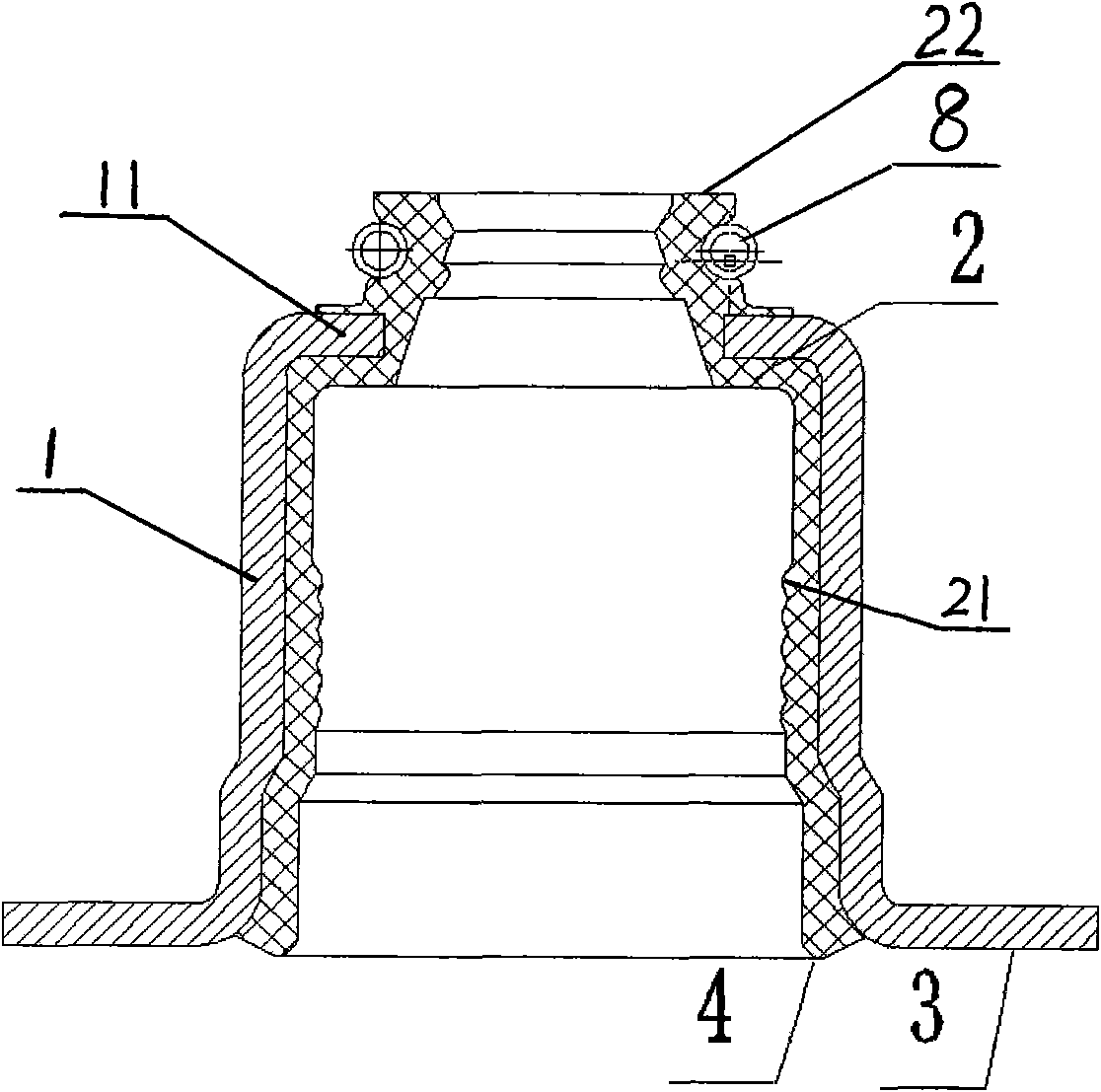

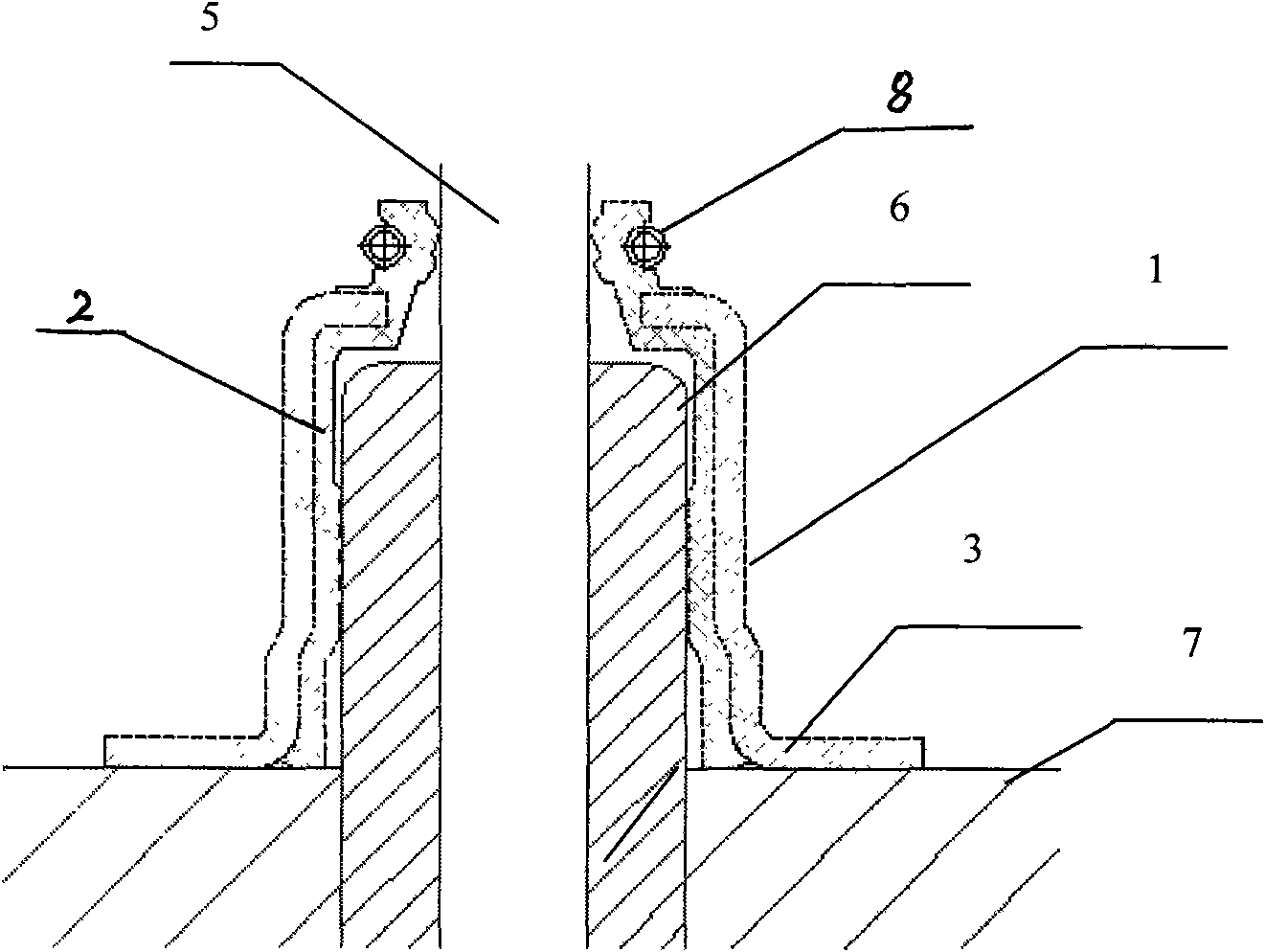

[0015] according to figure 1 As shown, the engine valve oil seal and valve spring seat combination includes a valve spring seat 1 and a valve oil seal 2 integrated into an integral composite structure. The valve oil seal 2 is in the shape of a sleeve with openings at both ends. The valve spring base 1 is tightly fitted outside the valve oil seal 2. The middle section of the inner wall of the valve oil seal 2 has rubber protruding teeth 21 that are interference fit with the outer wall of the valve guide. The upper opening of the valve oil seal 2 is narrowed to form an upper lip 22 of a tight fitting valve, and the upper lip 22 protrudes beyond the upper opening of the valve spring base 1 . And the upper opening of the valve spring base has a closing edge 11, which is nested in the shoulder of the upper opening of the valve oil seal. The lower opening of the valve spring base has an eversion plane 3 which is in contact with the plane of the cylinder head and supports the valve ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap