Novel juxtaposed complex yarn towel

A composite yarn and yarn technology, which is applied in yarn, textiles, papermaking, household appliances, etc., can solve the problems of pollution, high hair loss rate, high cost, etc., and achieve the effect of reducing the maintenance process and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1 pure cotton class

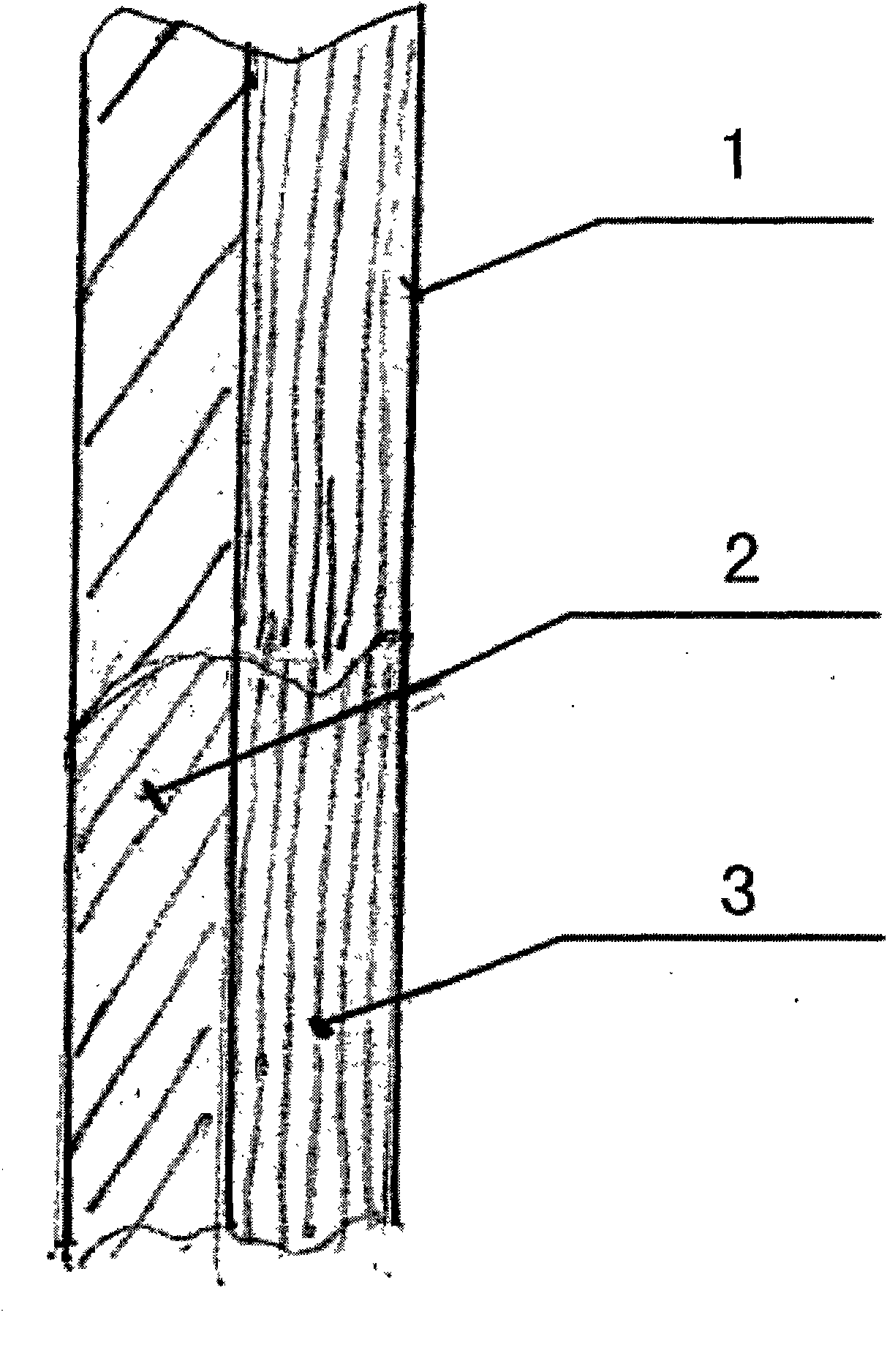

[0033] like figure 1 , figure 2 As shown, the pure cotton 60S core yarn is used as the skeleton yarn 2, and the pure cotton 60S is used as the untwisted yarn 3, arranged in parallel and side by side, and bonded and compounded by acrylate with a solid content of 1 to 3% by weight to form a side-by-side composite yarn 1. The individual composite yarns are then directly woven into towels as wool warp yarns.

Embodiment 2

[0034] Embodiment 2 pure cotton

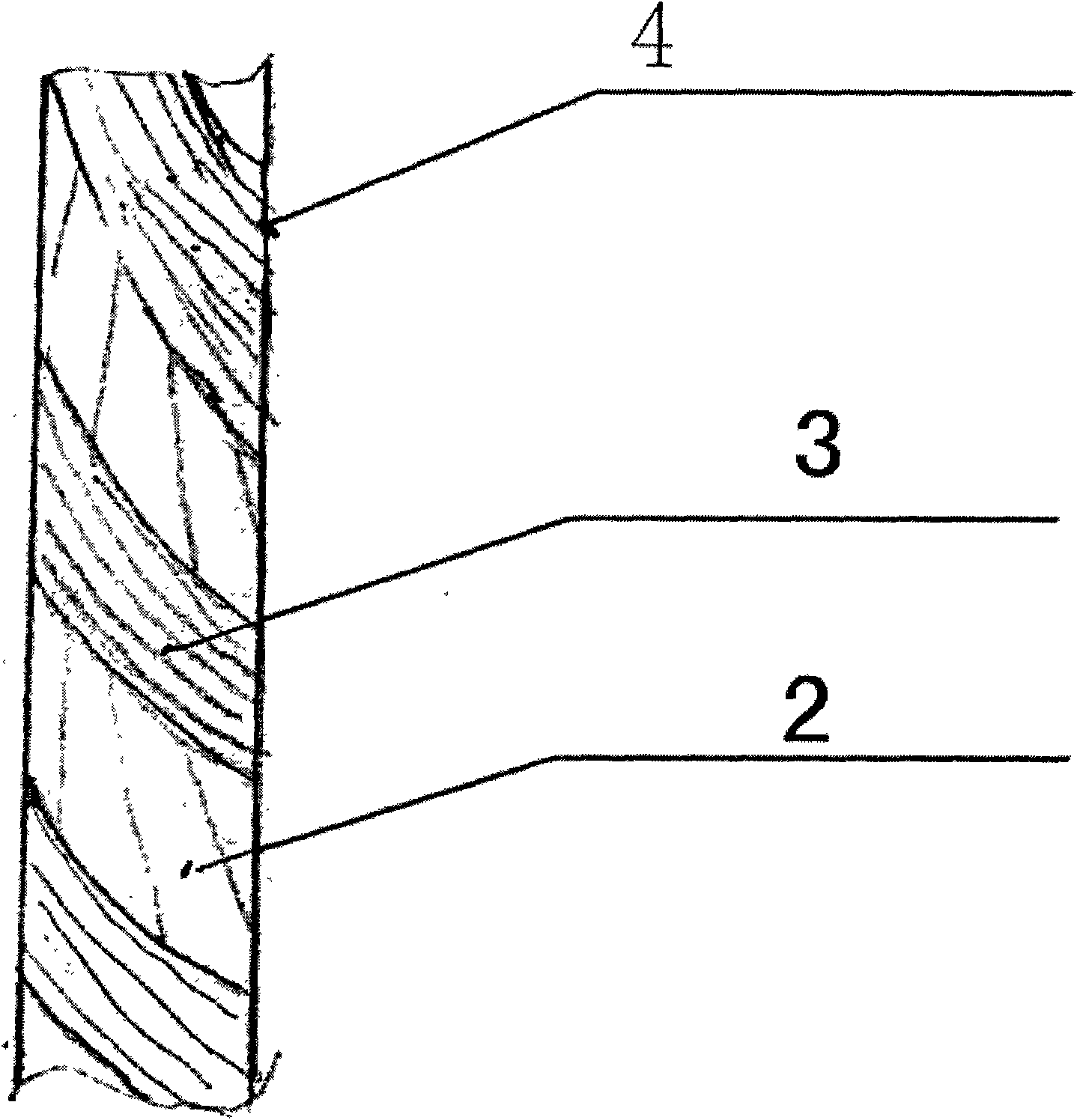

[0035] like figure 2 , image 3 As shown, the pure cotton 40S core yarn is used as the skeleton yarn 2, and the pure cotton 32S is used as the untwisted yarn 3, and then the single composite yarn is plied with S twist 14-20 twist / 10 cm, and a single twisted parallel composite yarn is obtained 4. Directly used as wool warp yarn to weave into towel.

Embodiment 3

[0036] Embodiment 3 cellulose blends

[0037] Pure bamboo pulp fiber 60S core yarn is juxtaposed with pure cotton 32S untwisted yarn, and then S-twisted 20-24 twists / 10 cm can be directly used as wool warp yarn to weave into towels.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com