Multifunctional fabric as well as preparation method and application thereof

A multi-functional, fabric technology, applied in fabrics, textiles, papermaking, knitting, etc., can solve problems such as multi-physical/chemical quantity sensing, luminescence, discoloration, thermal management, and less functions that cannot be realized simultaneously

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

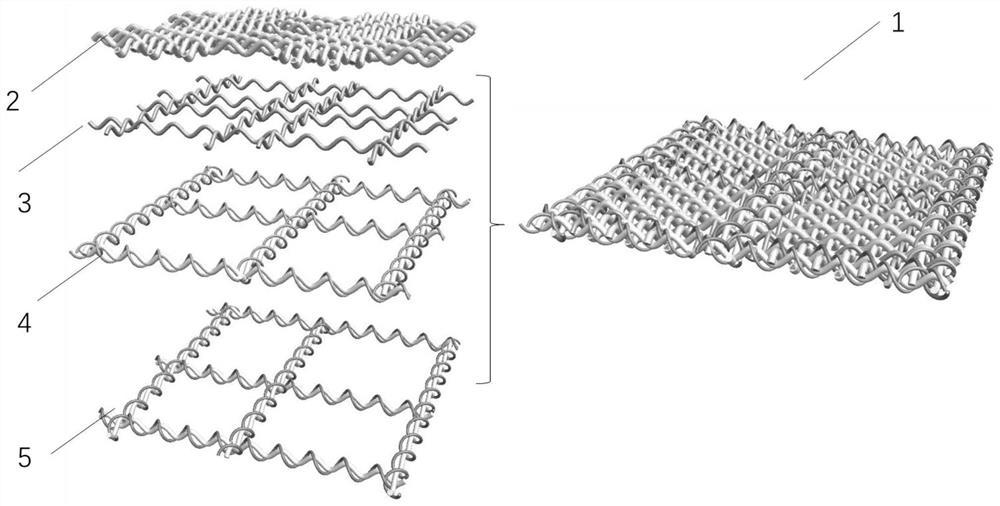

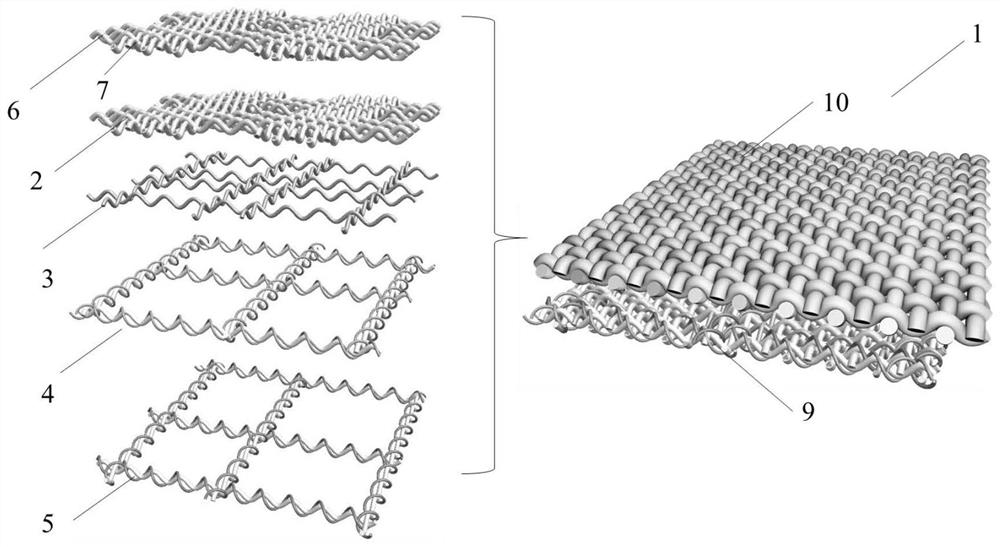

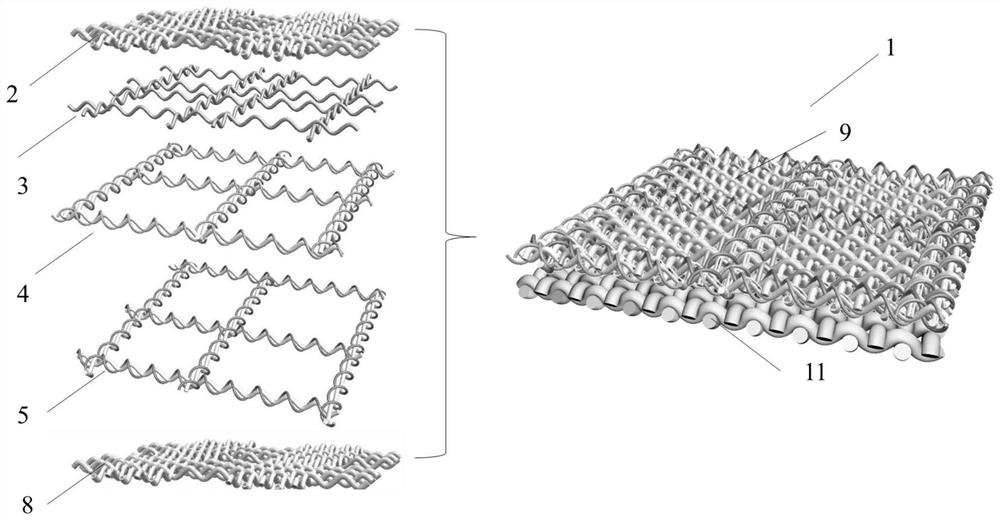

[0126] The present invention also provides a method for preparing the above-mentioned multifunctional fabric, and the sensor fiber and the functional fiber are prepared into a multifunctional fabric by using an embroidery method or a weaving method.

[0127] Wherein, the embroidery method is selected from wrong stitch embroidery, chaotic stitch embroidery, net embroidery, full-floor embroidery, thread lock, Nasi, Najin, flat gold, shadow gold, pan gold, velvet paving, scraping velvet, poking yarn, One or more of sprinkling thread and cross-stitching. The weaving method is selected from one or more of weaving, knitting, and integration of knitting and weaving.

[0128] The present invention also provides a distributed multifunctional textile device, such as Figure 5 As shown, the distributed multifunctional fabric device includes a multifunctional fabric 1, an analog-to-digital converter 12, a power supply, a Bluetooth transmission module 14, and a microprocessor 13, wherein ...

Embodiment 1

[0132] One, prepare pressure sensing fiber, concrete operation steps are as follows:

[0133] The preparation of the preform by hot pressing includes the following steps: (1) Weigh 60g of fluororesin and put it into a mold of 100mm x 22mm x 22mm (length x width x height). The mold is a stainless steel groove surrounded by Teflon Dragon film coating prevents the polymer material from sticking to the mold after heat softening. (2) Cover the upper and lower sides of the mold filled with fluororesin with stainless steel plates, and put it into the hot press to ensure that the force is uniform during the pressing process. Set the temperature on the hot press to 120°C, preheat the mixture in the mold at a pressure of 1 MPa for 3 minutes and then raise the pressure to 5 MPa, and repeat this step until the preform is formed. (3) Take out the hot-pressed preform with a punch and put it in a dry box for later use.

[0134] The preparation of the preform rod by extrusion method include...

Embodiment 2

[0150] The difference between Example 2 and Example 1 is that the preparation method of the pressure sensing fiber is different, thus, the obtained pressure sensing fiber is also different, and the specific operation steps are as follows:

[0151] The preparation method of the preform is the same as that in Example 1, and 60 g of fluororesin is prepared by hot pressing or extrusion.

[0152] The processing of preparing a preform with 3 axial through holes (the three through holes form an equilateral triangle on the cross section of the preform, and the axis of the preform is located at the center of the equilateral triangle) includes the following steps: (1) The above-prepared preform is placed in a lathe fixture, and the preform is processed by adjusting the speed and feed distance. The lathe speed is 150-300r / min, and the preform is processed into a circle with a diameter of 20mm and a length of 100mm by the lathe. (2) The preform bar processed by the above lathe is axially ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com