Expanding hydraulic anchor

A hydraulic anchor and expansion type technology, applied in wellbore/well components, earthwork drilling, etc., can solve the problems of oil well engineering accidents, anchor claw stuck pipe string, unable to carry out oil well operations, etc., to achieve reliable work and avoid engineering effect of accident

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

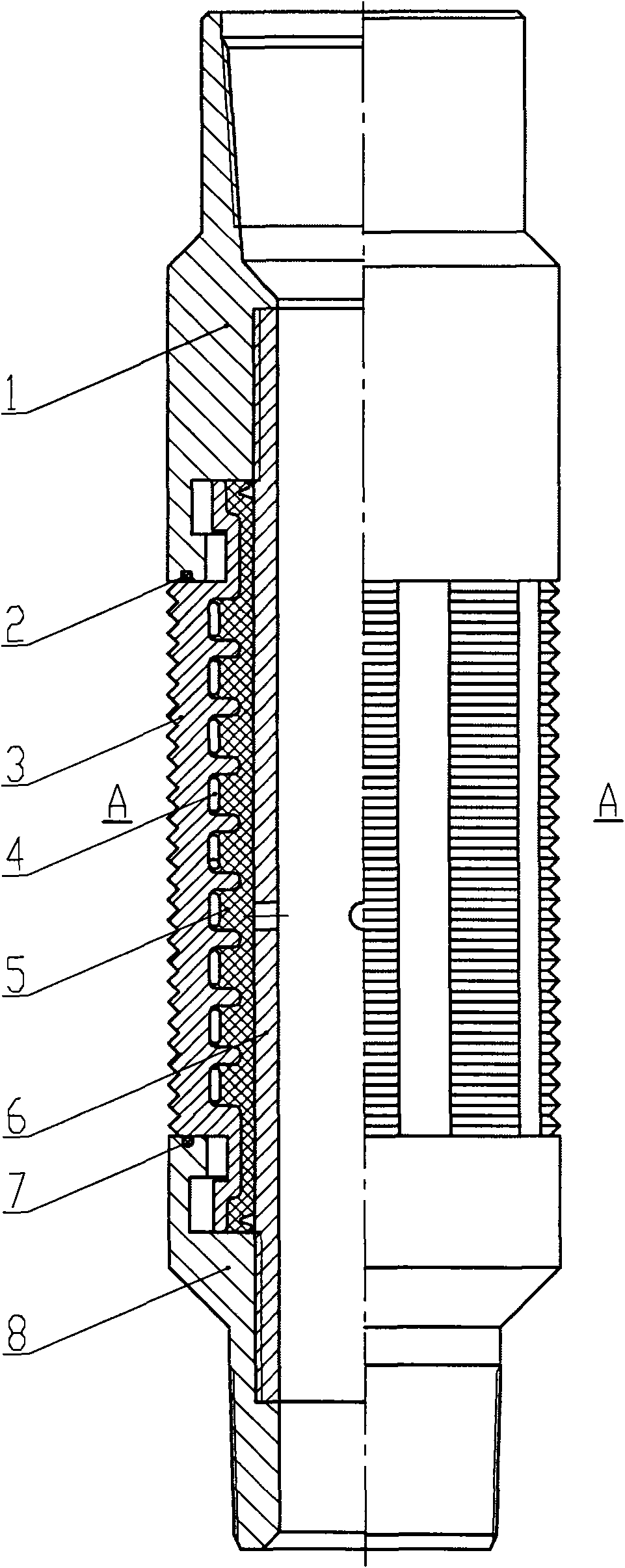

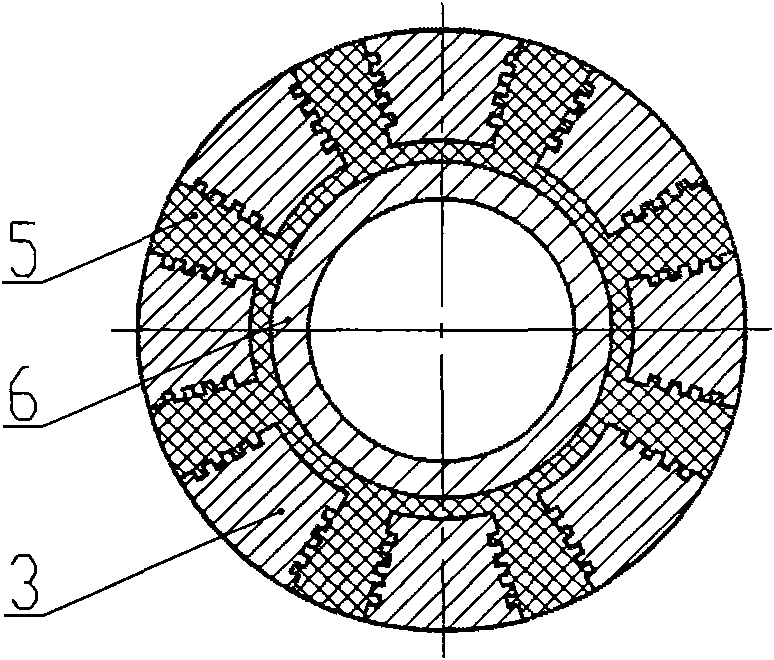

[0010] Attached below figure 1 , 2 Examples of the present invention will be described.

[0011] It is composed of upper joint 1, upper sand ring 2, anchor claw 3, hoop spring 4, rubber tube 5, inner tube 6, lower sand ring 7, and lower joint 8. The anchor claw 3 is embedded in the rubber tube 5 in strip shape. In the longitudinal groove, there are transverse teeth on the outer side of the anchor claw 3, which are used for anchoring the casing, and there are radial grooves on the inner side of the anchor claw 3, and there is a hoop spring 4 in the radial groove, and the hoop spring 4 encloses the rubber tube 5, Anchor fluke 3, hoop spring 4, and rubber tube 5 are vulcanized into one body and set outside the inner tube 6. The upper part of the inner tube 6 is connected with the upper joint 1, the lower part of the inner tube 6 is connected with the lower joint 8, and the lower part of the upper joint 1 buckles the anchor fluke 3 The upper part makes the fluke 3 tops not fall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com