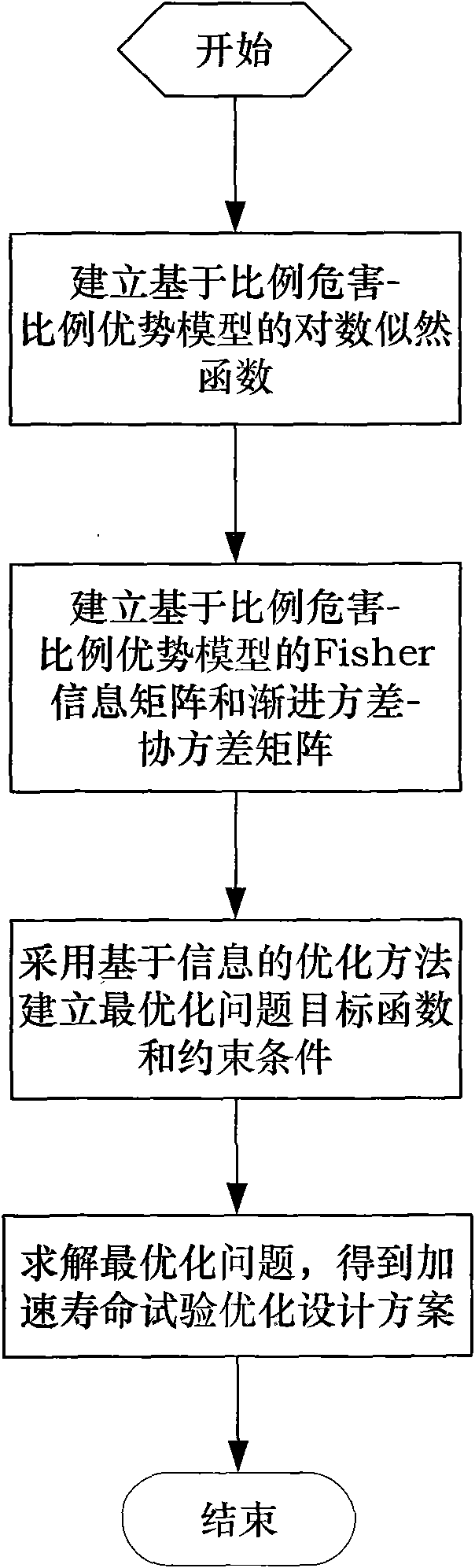

Accelerated life test optimization design method based on proportional hazards-proportional odds model

A technology for accelerated life testing and optimization design, applied in the testing of machine/structural components, measuring devices, instruments, etc., to avoid inconsistent optimization results, wide application range and evaluation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

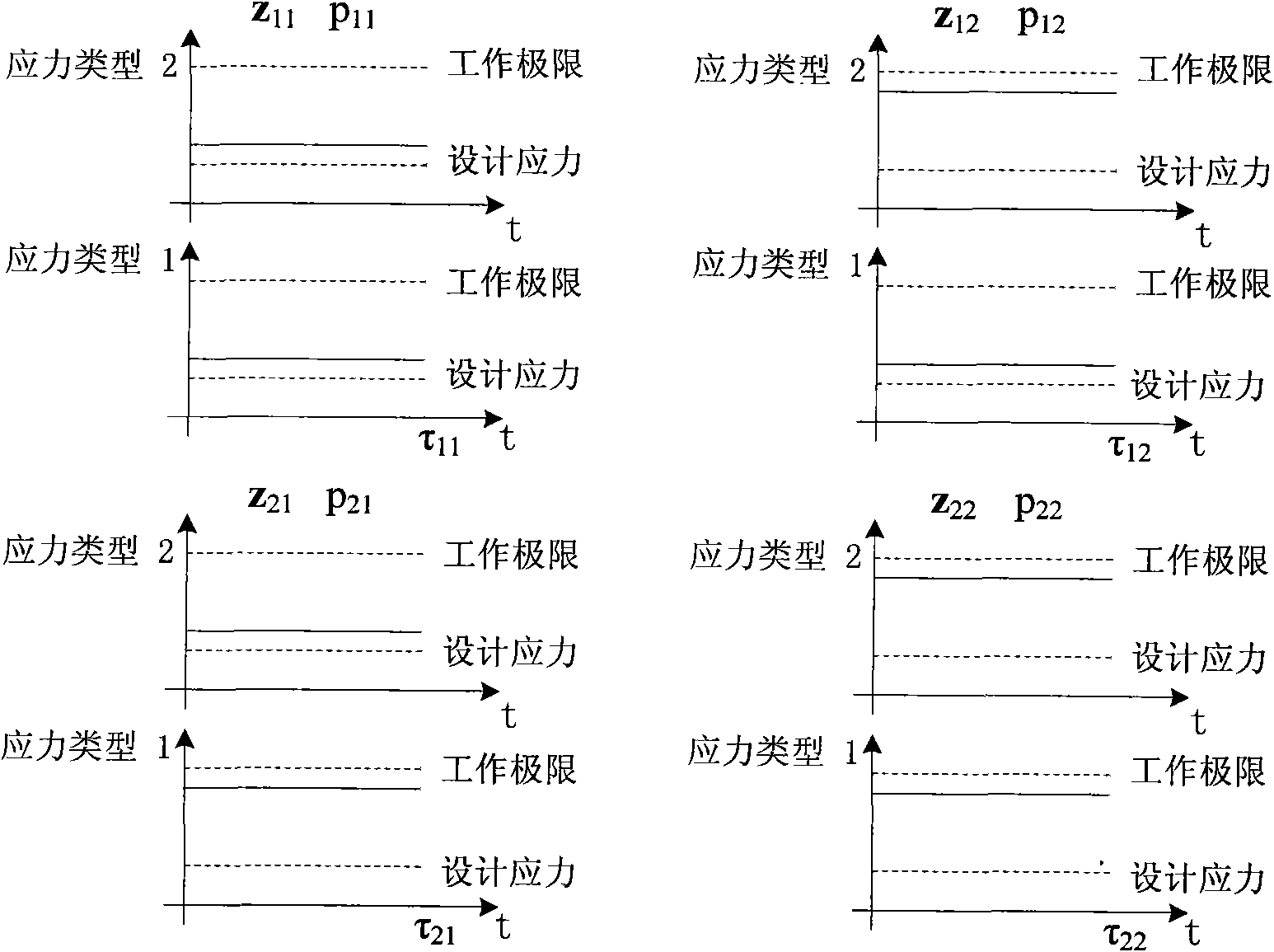

[0191] Embodiment 1: constant stress accelerated life test optimization design;

[0192] Assume that a product undergoes a three-level constant stress accelerated life test, and the test stress is temperature stress. The number of test products available is 300. The operating limit of the tested product is 200°C. For each stress level, the censored time was 300 hours, and at least 20 tested products were required to fail at each stress level.

[0193] The temperature stress level value is converted to 100K according to the Arrhenius model -1 , therefore, the normal stress level of 25°C and the product working limit stress level of 200°C are converted to 0.336 and 0.211, respectively. Using the proportional hazards-proportional advantages model to evaluate the failure data of the accelerated life test pre-test of the product, the estimated values of the model parameters are: β=-60, c=0.5, α=2, γ=3. The estimated values of these model parameters will be used in the accel...

Embodiment 2

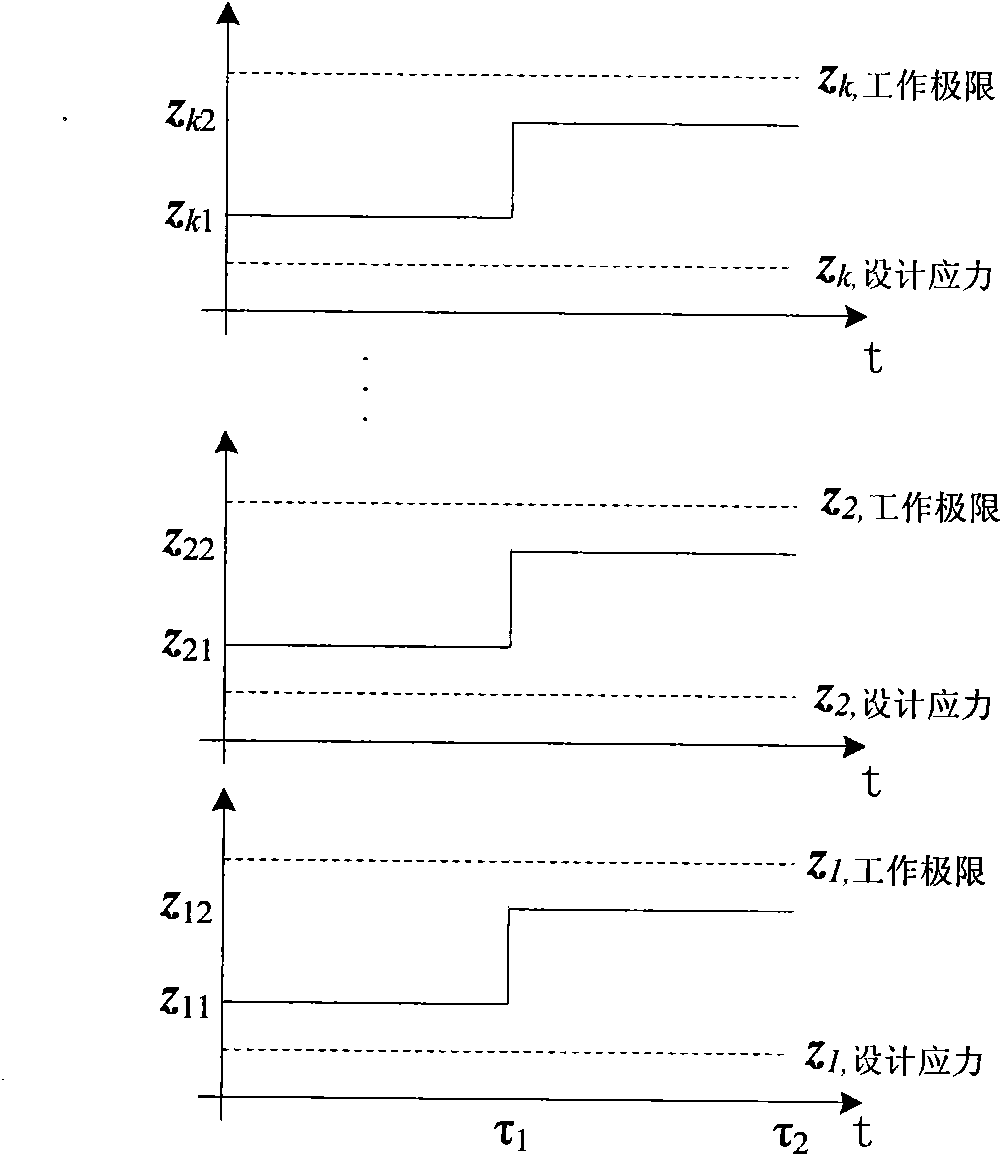

[0212] Embodiment 2: step stress accelerated life test optimization design;

[0213] Assume that a product undergoes two-level step stress accelerated life test, and the test stress is temperature stress. The number of test products available is 300. The working limit of the tested product is 210°C. Test at low stress level z 1 carry out τ 1 After time, go to high stress level z 2 (Take the stress level value slightly lower than the working limit of the product at 200°C), and at τ 2 = 300 hours censored. Requires a low stress level z 1 At least 50 tested products failed.

[0214] The temperature stress level value is converted to 100K according to the Arrhenius model -1 , therefore, the normal stress level of 25°C and the high stress level of 200°C translate to 0.336 and 0.211, respectively. Using the proportional hazards-proportional advantages model to evaluate the failure data of the accelerated life test pre-test of the product, the estimated values of the model...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com