Synchronous belt

A synchronous belt and pulley technology, applied in the field of belt transmission, can solve problems such as flat belts and round belts are easy to slip, double-sided V-belts have poor flexibility, and affect transmission efficiency, and achieve smooth and soft transmission, constant transmission ratio, The effect of high transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

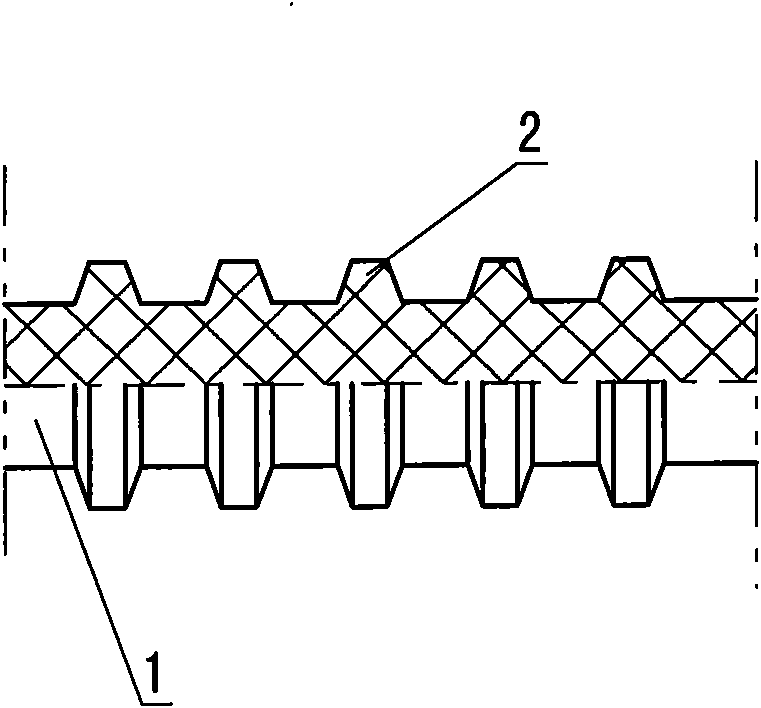

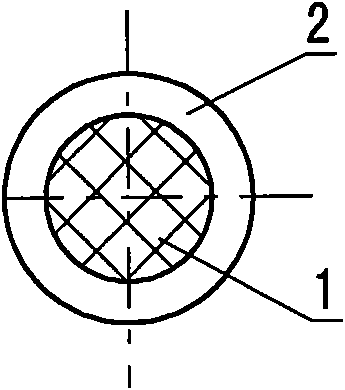

[0014] combine figure 1 , figure 2 , a synchronous belt, its base shape is a circular elongated ring, the synchronous belt 1 is provided with protruding teeth 2 arranged in sequence, its cross section is circular, and its longitudinal section is a double-sided rack shape.

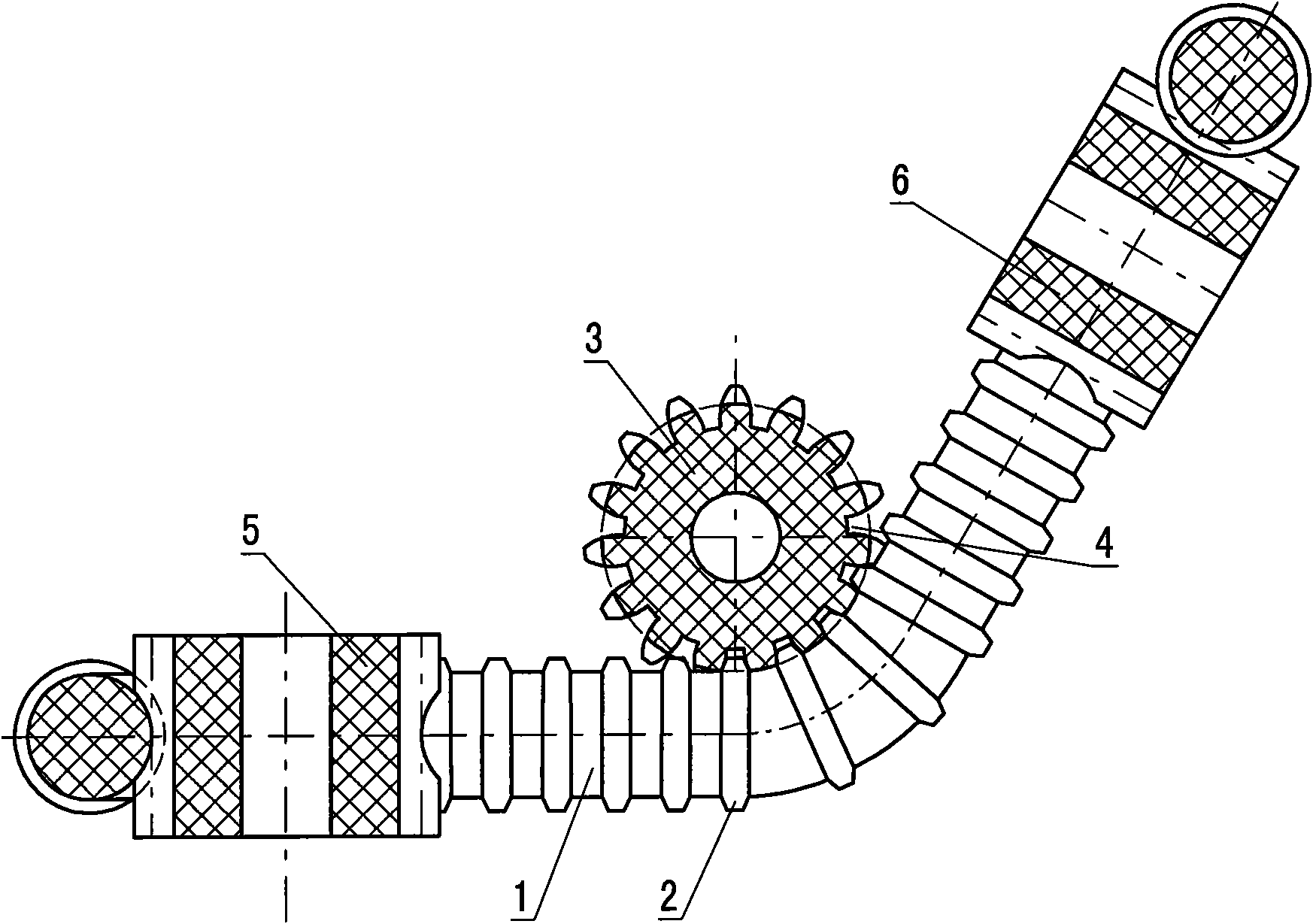

[0015] combine image 3 , is a schematic diagram of hybrid transmission of intersecting shafts and staggered shafts in this embodiment. In the figure, power is transmitted between the driving pulley 5, the driven pulley 6 and the guide pulley or tensioning pulley 3 through the synchronous belt 1, wherein the driving pulley 5 and driven pulley 6 belong to intersecting shaft transmission, and between driving pulley 5 and guide pulley or tension pulley 3 belong to interlaced shaft transmission. The driving pulley 6 and the guide pulley or the tensioning pulley 3 are provided with concave tooth grooves 4 that mesh with the synchronous belt 1, and they will not slip during transmission; since the base shape ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com