Probe card corrector

A technology for calibrating equipment and probe cards, applied to measuring devices, instruments, and optical devices, etc., can solve problems such as labor and time consumption, poor calibration accuracy, and inconvenience in use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

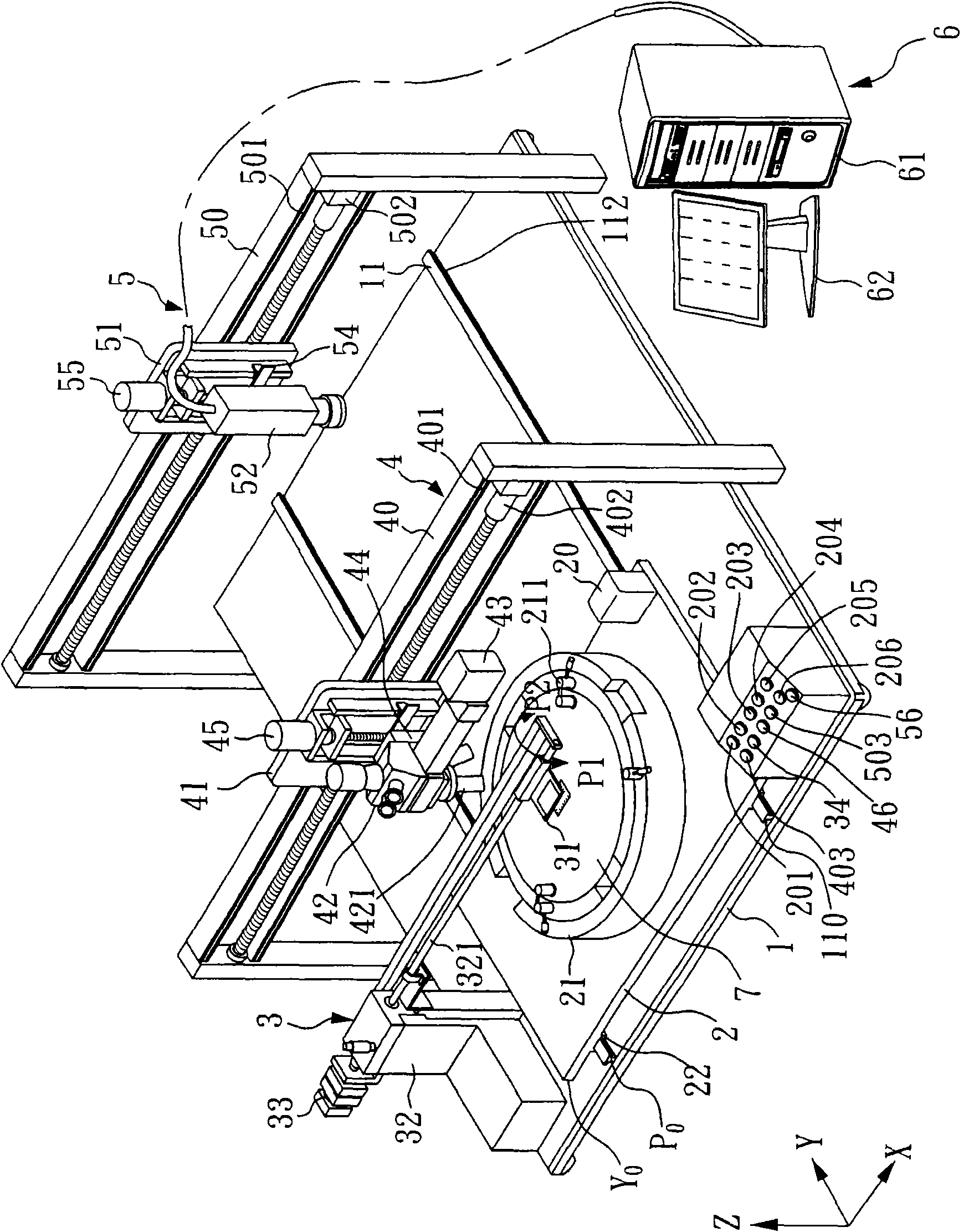

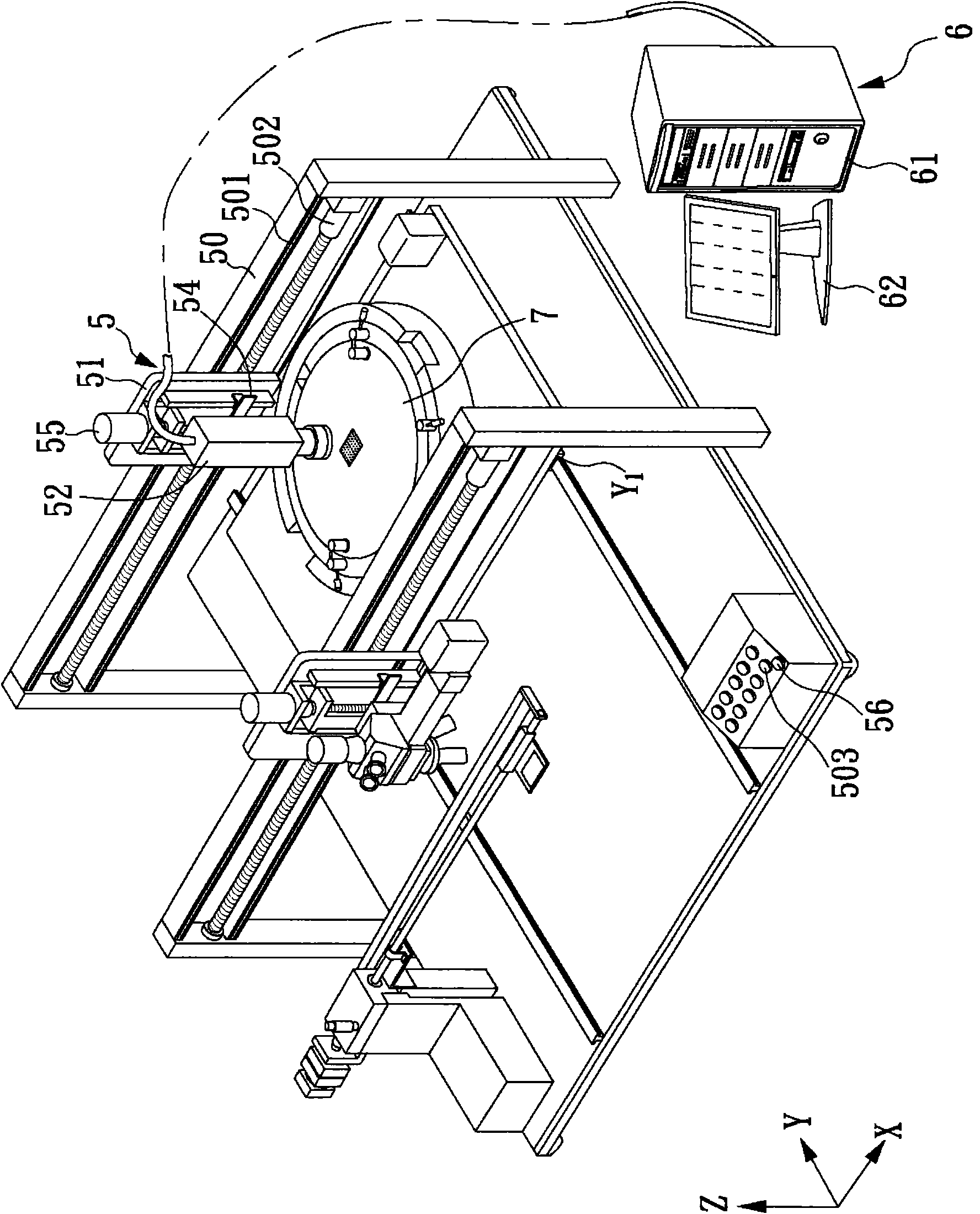

[0043] see figure 1 , is a perspective view of a preferred embodiment of the present invention. As shown in the figure, this embodiment relates to a probe card calibration device, which includes a base 1, a mobile platform 2, a comparison device 3, a microscopic device 4, and a height measurement device 5.

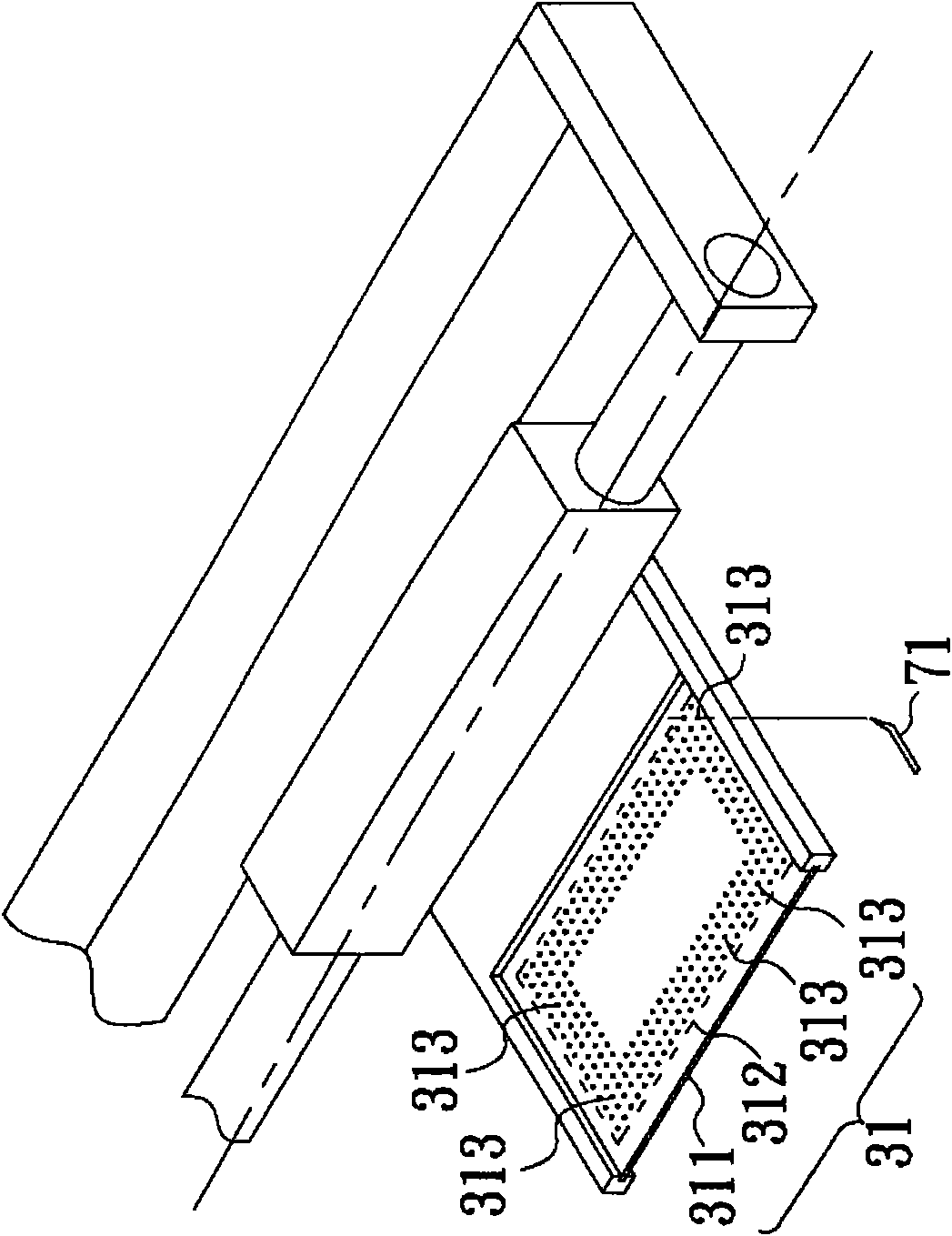

[0044] The base 1 includes a first guiding device, and the first guiding device includes a first end 110 and a second end 112 , wherein the first guiding device refers to two sliding rails 11 . The mobile platform 2 includes a second guide device and a rotating platform 21, wherein the second guide device refers to two sliding seats 22, which relatively slide on the two slide rails 11, and the mobile platform 2 passes through the second guide The two sliding seats 22 of the guiding device are correspondingly slid on the two sliding rails 11 of the first guiding device of the base 1, and relatively slide between the first end 110 and the second end 112, and the rotating s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com