Rolling element retaining chain unit

A technology of rolling elements and holding chains, which is applied in the direction of linear motion bearings, bearings, shafts and bearings, etc., can solve problems such as unstable jumping, unsteady operation, etc., and achieve the effect of increasing tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

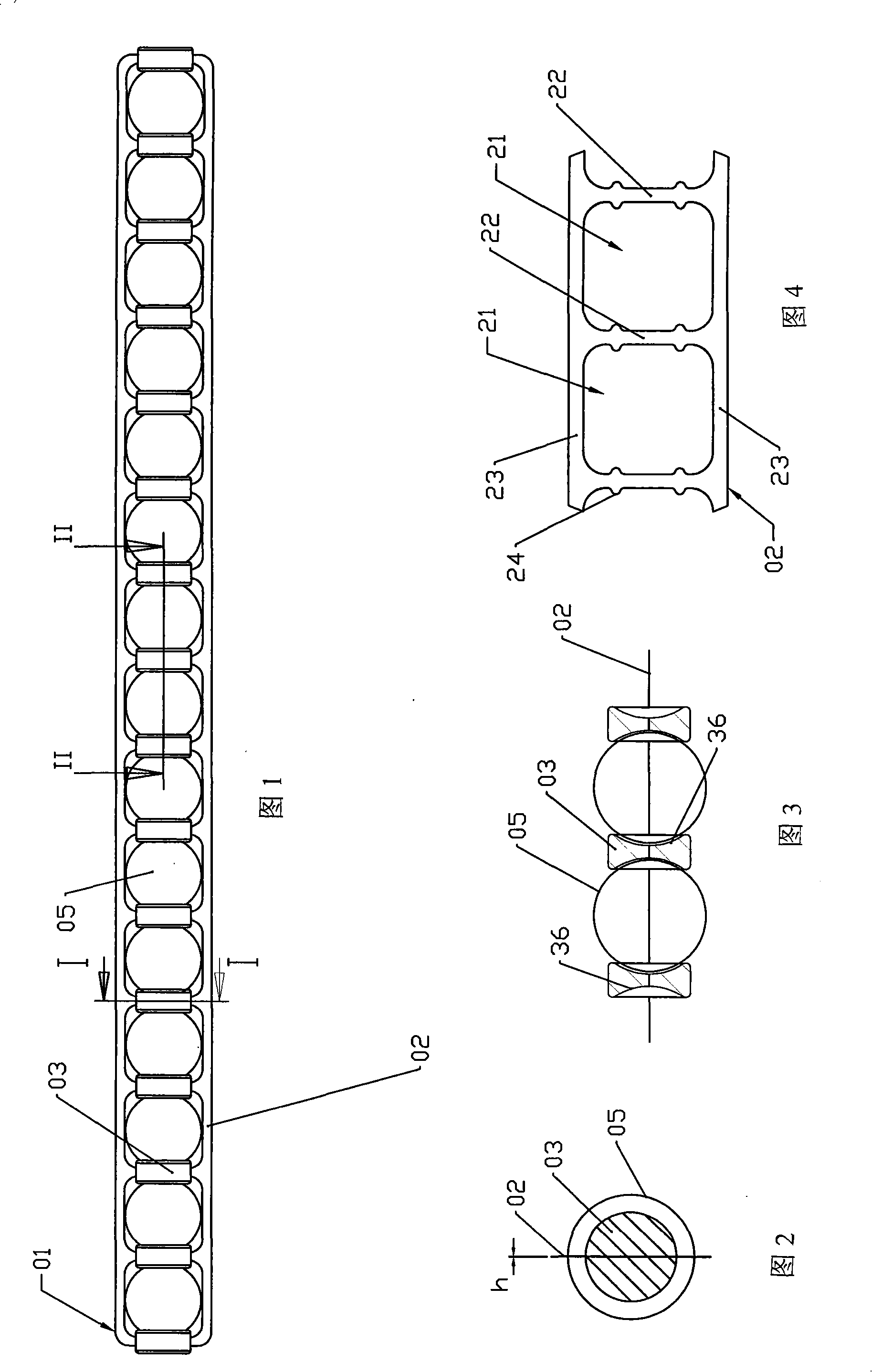

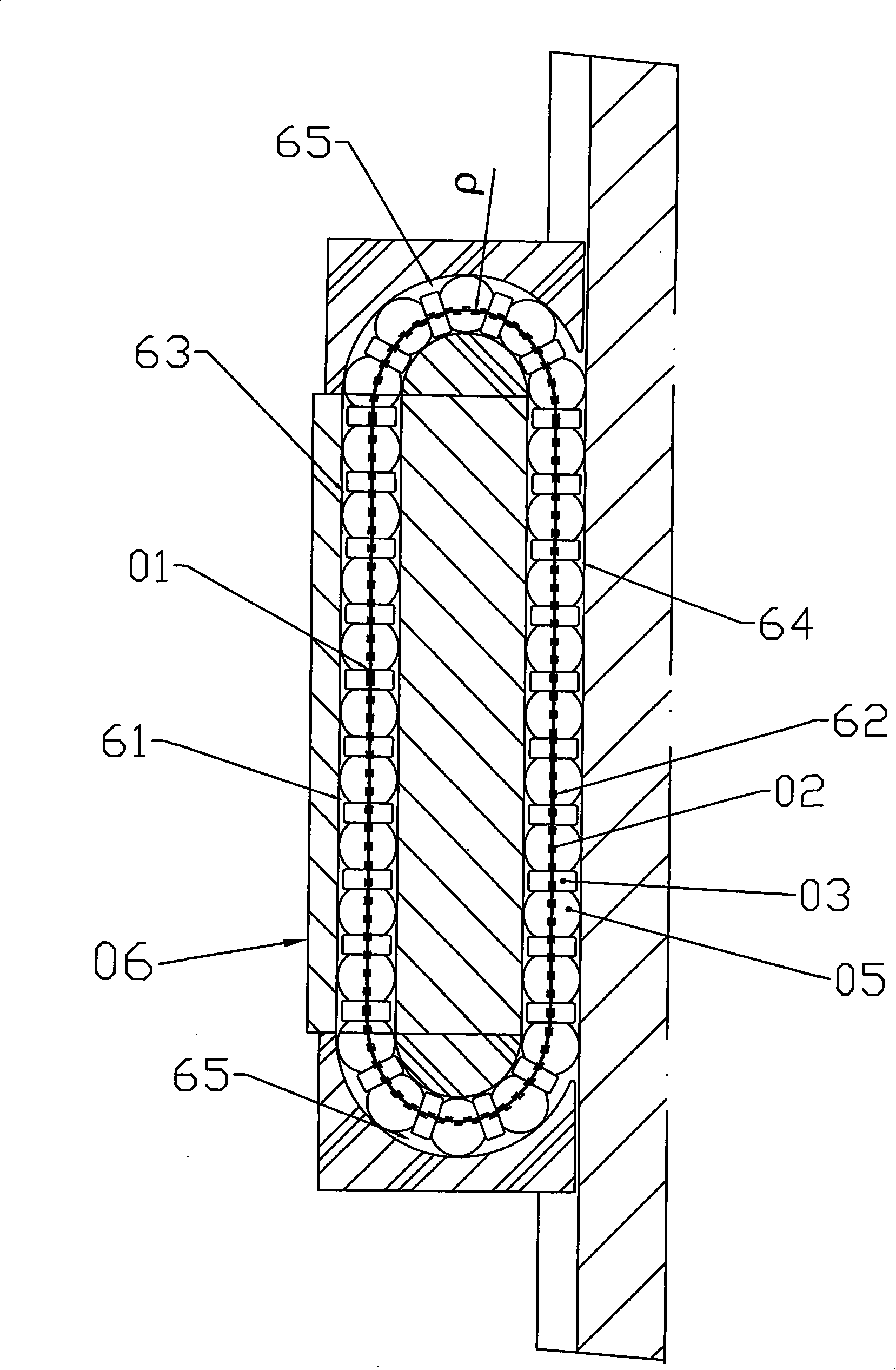

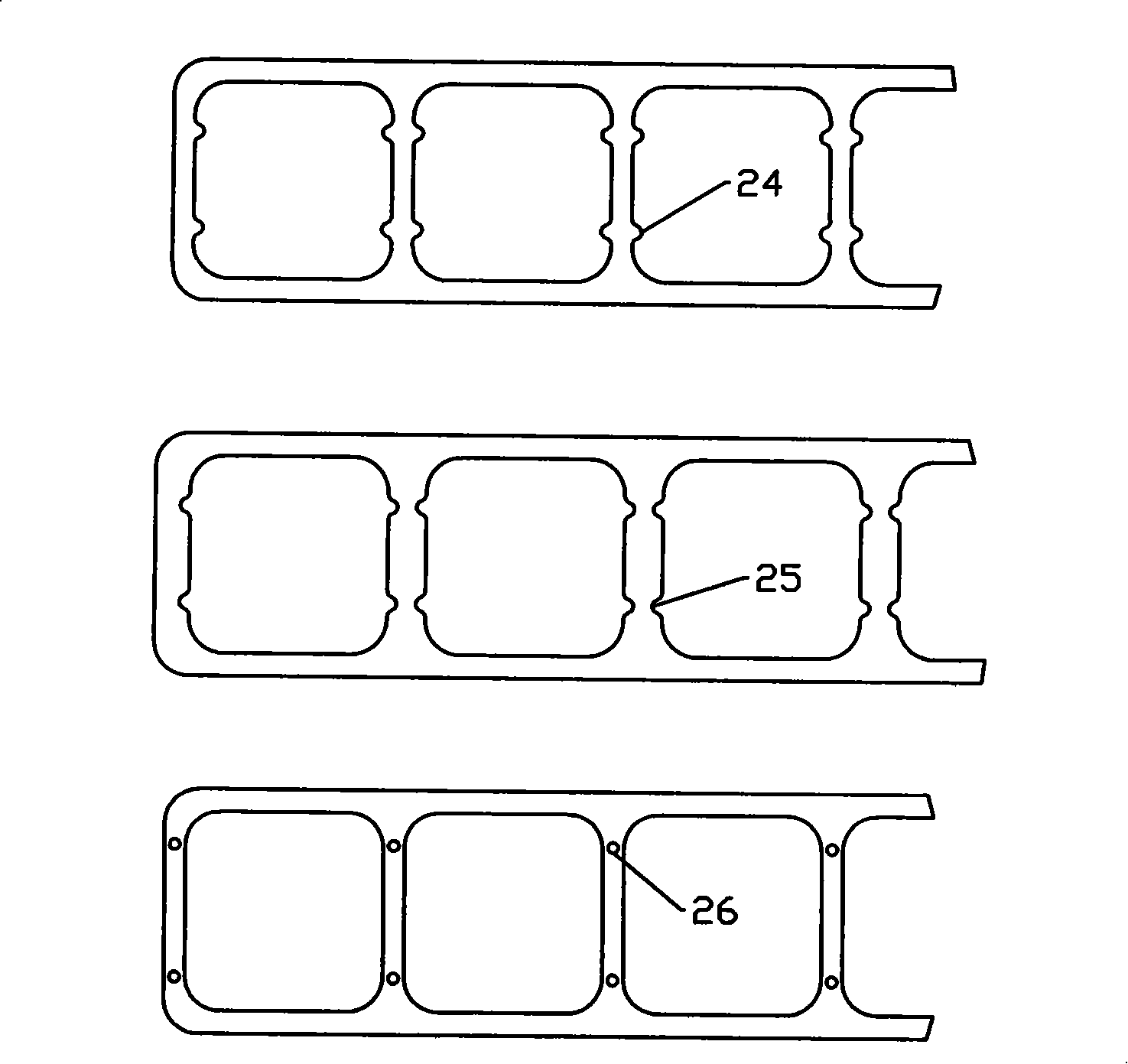

[0075] Such as figure 1 , figure 2 As shown, a rolling element retaining chain 01 is designed to consist of a flexible metal sheet 02 and a plurality of spacers 03 , wherein the flexible metal sheet 02 has holes 21 arranged axially. Such as Figure 4 As shown, a horizontal bar 22 is formed between the holes 21 to separate the two holes 21, and the spacer block 03 is combined on the horizontal bar 22; a connecting bar 23 is formed on the upper and lower sides of the hole 21, and all the horizontal bars 22 are connected to the connecting bar 23 Above: a row of rolling elements, including a plurality of rolling elements 05, each rolling element 05 is held in each hole 21 and separated by two spacers 03; as image 3 As shown, the surface of the spacer block 03 corresponding to the rolling body 05 is in a covered shape 36, and the rolling body 05 is held in the rolling body holding chain 01 between the two spacer blocks 03 that are in a covered shape 36 on the left and right an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com