Method of improving superelasticity of NiTiCrRE shape memory alloy through solid solution treatment

A memory alloy and solution treatment technology, applied in the field of shape memory alloys, can solve problems such as unpublished patents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] The selected components are: Ni: 55.6wt%; Ti: 42.43wt%; Cr: 0.71wt%; RE: 1.26wt%. A NiTiCrRE shape memory alloy wire with a length of 12 cm and a diameter of 1.16 mm.

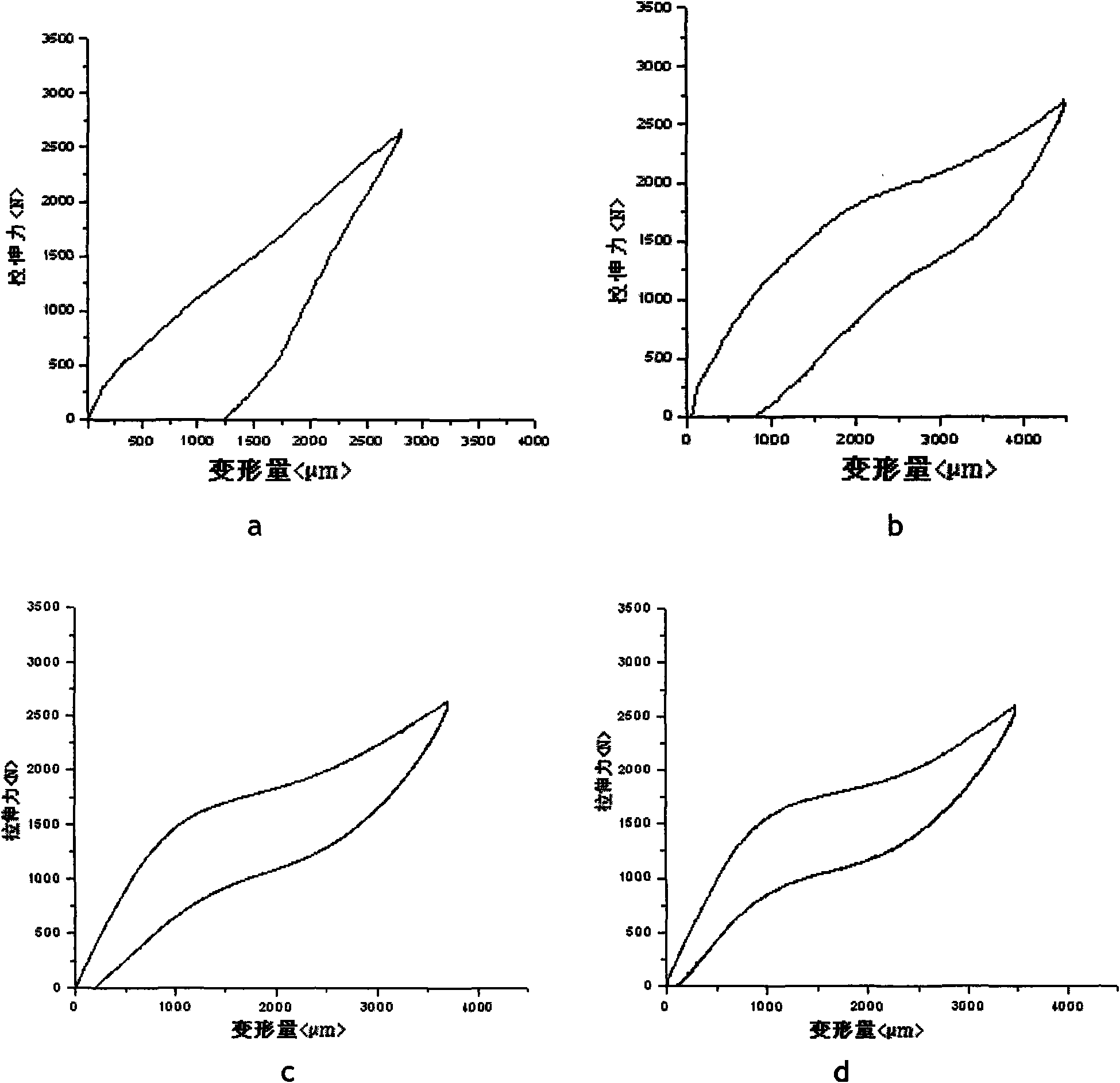

[0012] After heat preservation at 620°C for 40 minutes, heat preservation at 660°C for 40 minutes, heat preservation at 680°C for 40 minutes, and heat preservation at 680°C for 80 minutes after solution treatment and aging, the tensile test was carried out on a WDW-10 computer-controlled electronic universal tensile testing machine. Different tensile force-deformation relationship curves are obtained. Through the tensile test curve (see figure 1 ) It can be seen that when the solution temperature is lower than 700 °C, the alloy cannot exhibit complete nonlinear superelasticity, but with the increase of the solution temperature and the extension of the holding time, the residual deformation of the alloy is continuously decreasing. This shows that the superelasticity of the alloy increases with the incre...

Embodiment 2

[0014] The selected components are: Ni: 56.1wt%; Ti: 41.91wt%; Cr: 0.58wt%; RE: 1.41wt%. A NiTiCrRE shape memory alloy wire with a length of 12 cm and a diameter of 1.21 mm.

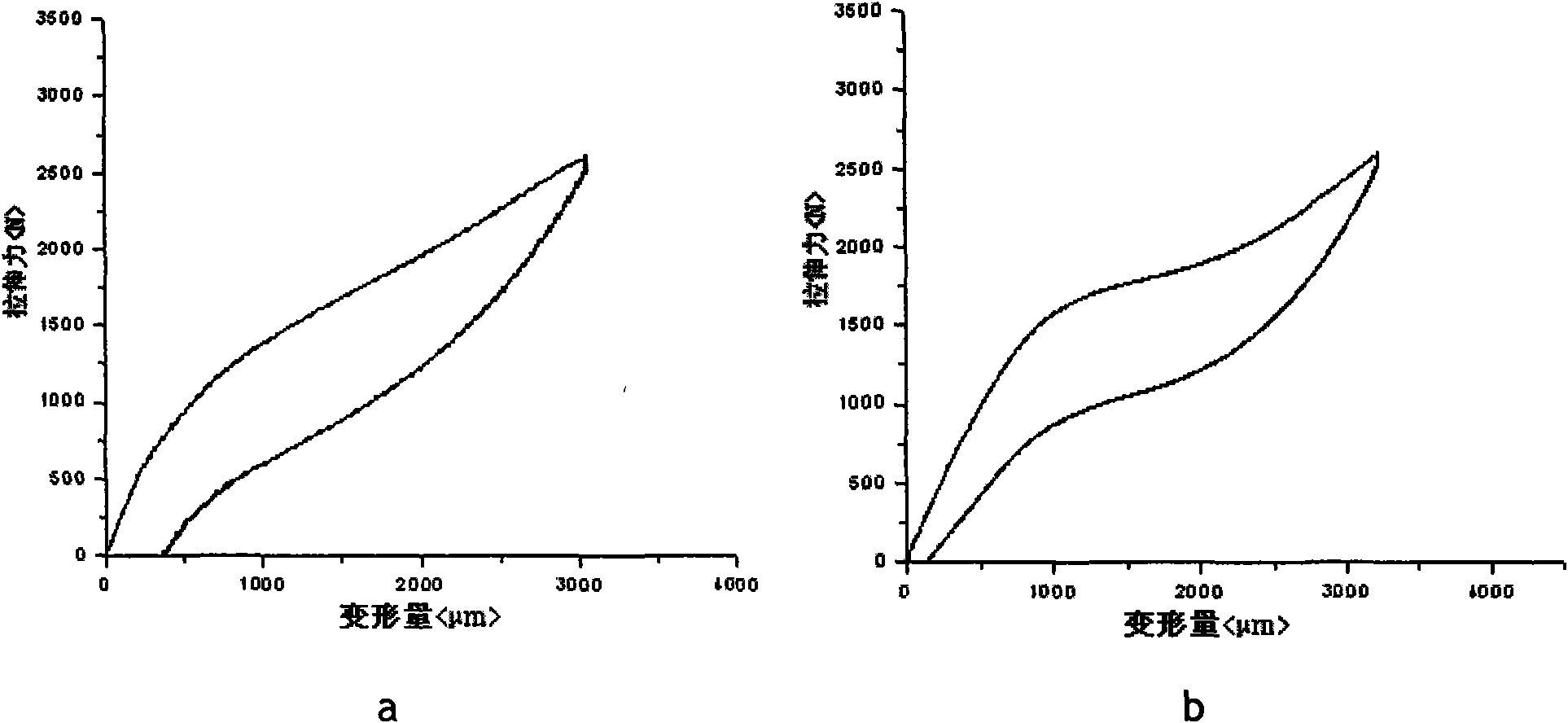

[0015] Put the memory alloy wire after solid solution treatment and aging at 700°C on a WDW-10 microcomputer-controlled electronic universal tensile testing machine for tensile test. The loading rate of the test is 1mm / min, and it is kept at 2.7KN for 2 seconds. After 10 minutes, unload at a rate of 1 mm / min to obtain different tensile force-deformation curves. Through the tensile test curve (see figure 2 ) It can be seen that when the solution temperature reaches 700°C, the elasticity of the alloy increases continuously with the increase of the holding time, and after the holding time reaches 60 minutes, the sample reaches complete nonlinear superelasticity. However, when the holding time continues to increase, the residual deformation of the alloy ( figure 2 -d) increases instead, and the superela...

Embodiment 3

[0017] The selected composition is Ni: 57wt%; Ti: 41.05wt%; Cr: 0.65wt%; RE: 1.3wt%. A NiTiCrRE shape memory alloy wire with a length of 13 cm and a diameter of 1.29 mm.

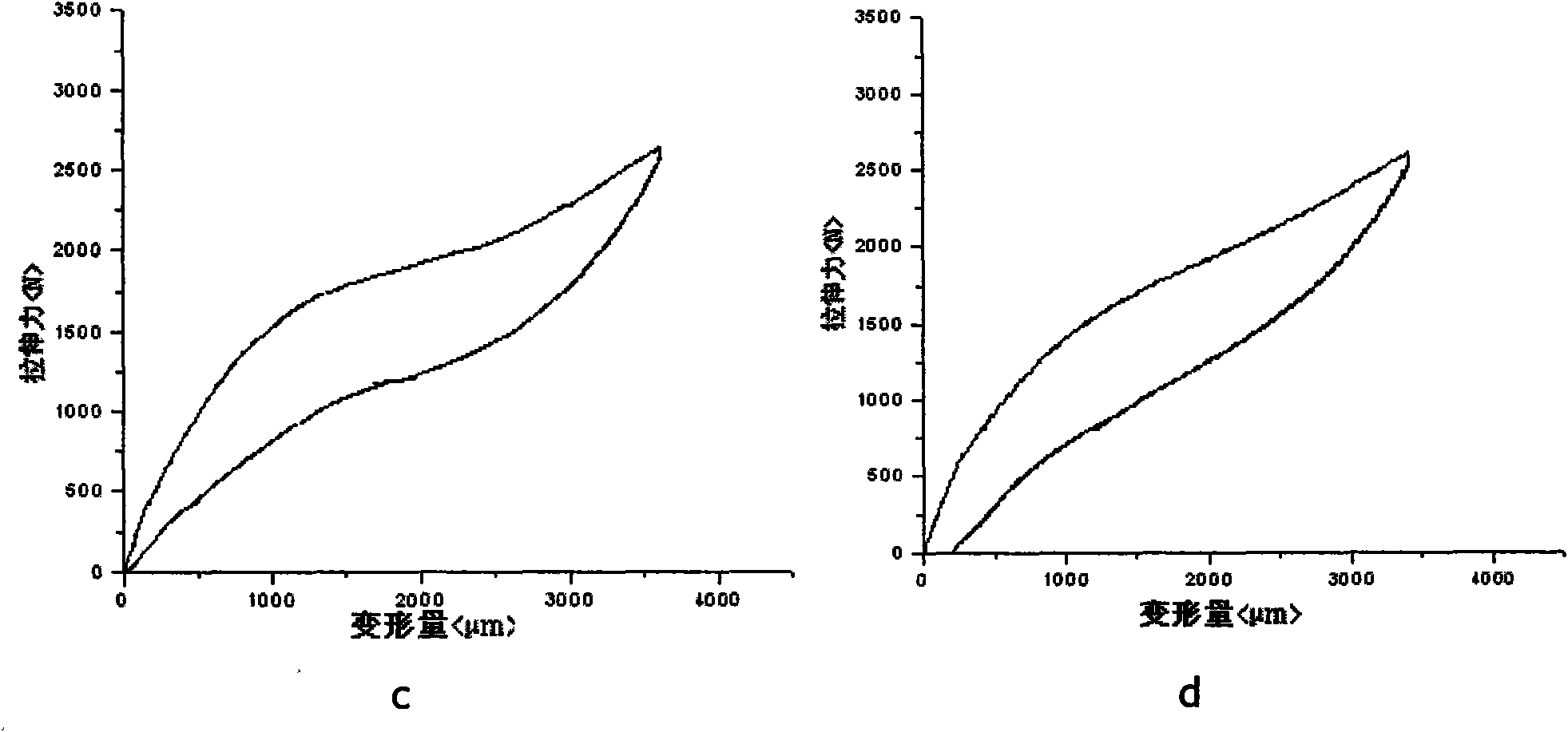

[0018] Put the memory alloy wire after solid solution treatment and aging at 720°C on a WDW-10 microcomputer-controlled electronic universal tensile testing machine for tensile test. The loading rate of the test is 1mm / min, and it is kept at 2.7KN for 2 seconds. After 10 minutes, unload at a rate of 1 mm / min to obtain different tensile force-deformation curves. Depend on image 3 It can be seen that the sample cannot exhibit complete nonlinear hyperelasticity, and has a large residual deformation. In a small holding time, the superelasticity of the sample ( image 3 -a, b) increase with time, but as the holding time increases, when the alloy is held at 720°C for 60 minutes, the superelasticity of the alloy decreases instead ( image 3 -c); when the holding time continues to increase, the residual deforma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com