Ni-Ti-based shape memory alloy for manufacturing vibration damper of engineering structures

A memory alloy and vibration damping device technology, applied in building components, shockproof, etc., can solve the problems of irrecoverable, unpublished patents, deterioration of structural fatigue strength and vibration environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

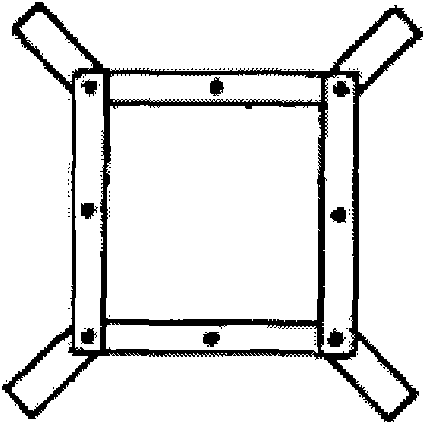

Image

Examples

Embodiment 1

[0009] According to the method of the invention, the NiTi-based shape memory alloy is subjected to solid solution treatment, and its composition range is: Ni: 55.1wt%; Ti: 41.5wt%; Cr: 0.4wt%; compound rare earth RE: 0.1wt%. After 700°C solid solution heat preservation treatment for 60 minutes, and then aging treatment, the alloy will show complete nonlinear superelasticity and achieve the best superelastic performance.

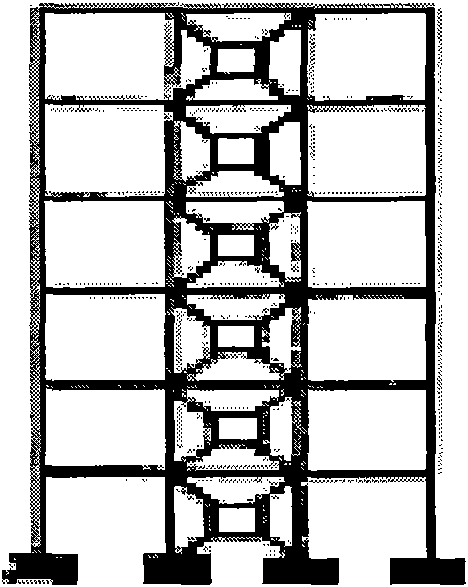

[0010] The NiTi-based shape memory alloy prepared above was installed in such as figure 2 The engineering frame structure shown. When the frame vibrates, the mechanism deforms under force, and the NiTi-based shape memory alloy damping device also deforms at the same time. When the NiTi-based shape memory alloy damping device is in the nonlinear superelastic state, due to the pseudoelastic effect of the shape memory alloy, the deformation of the alloy plate will recover when the frame vibration returns to the equilibrium position in a large deformation range...

Embodiment 2

[0012] According to the method of the invention, solid solution treatment is carried out on the NiTi-based shape memory alloy, and its composition range is: Ni: 57.5wt%; Ti: 43.7wt%; Cr: 0.9wt%; compound rare earth RE: 2wt%. After 700°C solid solution heat preservation treatment for 60 minutes, and then aging treatment, the alloy will show complete nonlinear superelasticity and achieve the best superelastic performance.

[0013] The NiTi-based shape memory alloy prepared above was installed in such as figure 2 On the engineering frame structure shown, the shock absorption effect is very good.

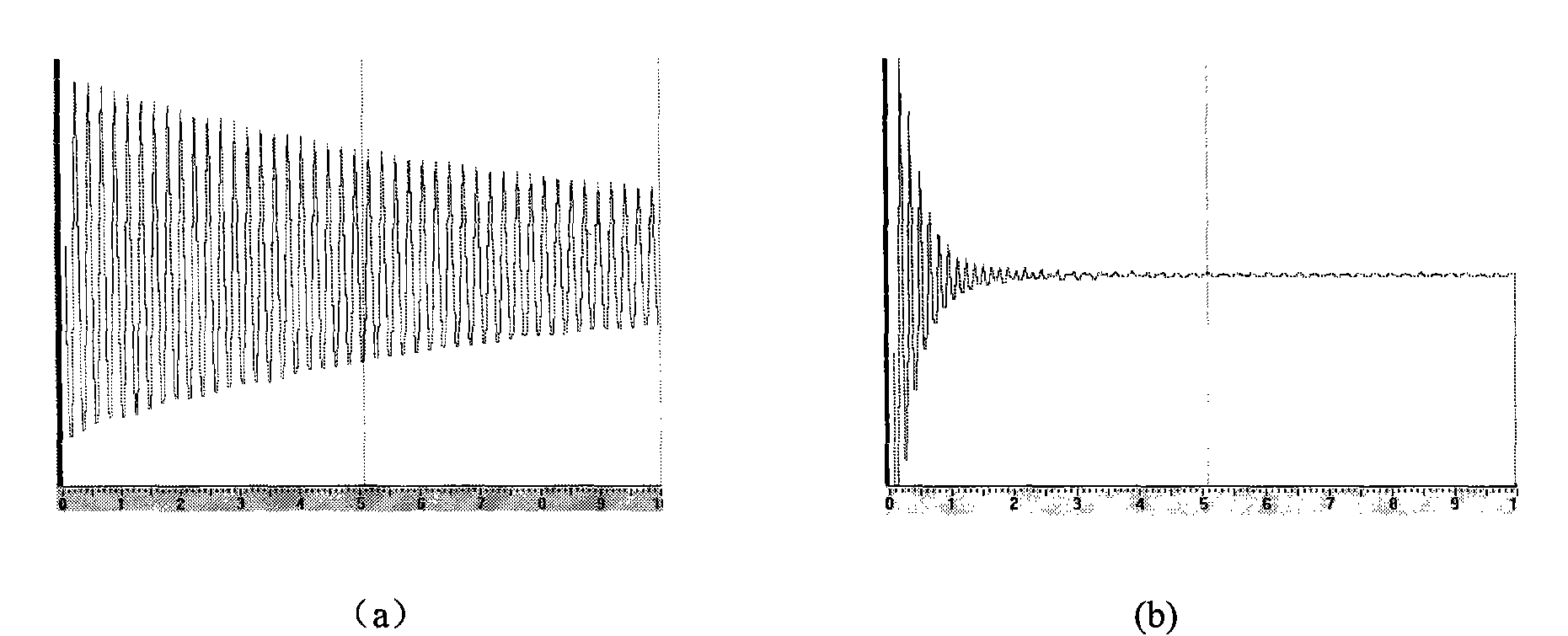

[0014] image 3 The attenuation effect comparison of installing ordinary vibration damping device and NiTi-based memory alloy vibration damping device respectively is given. image 3 (a) shows the vibration reduction situation of ordinary vibration reduction devices, and the vibration reduction effect is obviously not good. image 3 (b) shows the vibration reduction of the NiTi-base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com