Technique for enhancing super-elasticity of nickel titanium vanadium memory alloy by cold deformation

A memory alloy and superelastic technology, applied in the field of memory alloys, can solve the problems of lack of systematic research on martensite structure, no patents published, and few researches on memory alloys.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

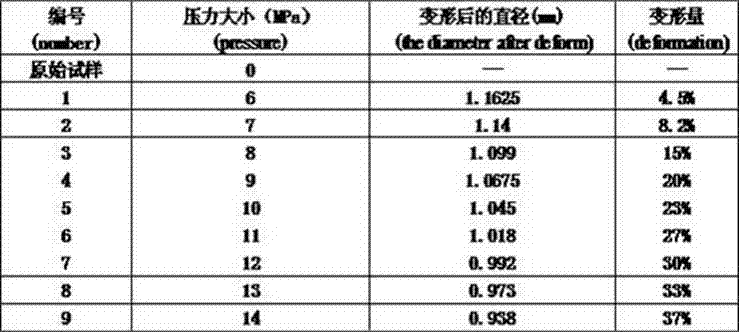

[0020] The selected composition is, Ni: 55.5wt%; Ti: 41.8t%; V: 0.57%. Phase transition point A f =-5°C memory alloy wire, cold deformed according to Table 1, select the NiCTir shape memory alloy wire with a length of 11cm and a diameter of 1.19mm, and use YJ-450 hydraulic forming machine to deform it by cold pressing. Use a pressure of 6MPa-14MPa (the wire will not be able to withstand the pressure and crack under a pressure greater than 14Mpa) to cold deform the memory alloy wire (the relationship between the pressure and the amount of cold deformation is determined by the formula to be calculated as shown in Table 1).

[0021] serial number Pressure size (MPa) Deformed thickness (mm) Cold deformation (%) original sample 0 — — 1 6 1.1625 4.5% 2 7 1.14 8.2% 3 8 1.099 15% 4 9 1.0675 20% 5 10 1.045 23% 6 11 1.018 27% 7 12 0.992 30% 8 13 0.973 33%

[0022] The cold-deformed memory alloy wire i...

Embodiment 2

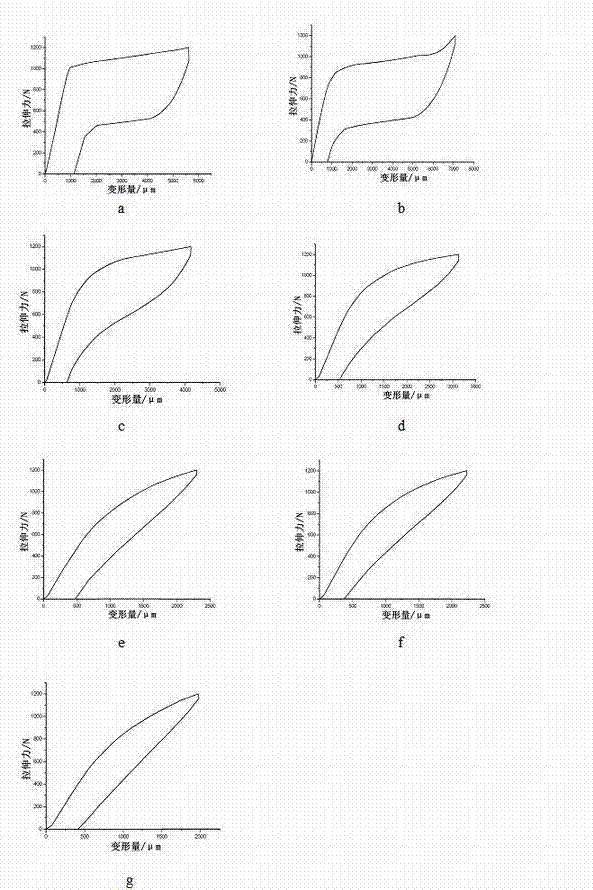

[0024] The selected composition is Ni: 57.3wt%; Ti: 43.4t%; V: 0.73%. , phase transition point A f =-35 ℃ of memory alloy wire, as in Example 1, cold deformation is carried out according to Table 1, and the memory alloy wire through cold deformation is subjected to a tensile test on a WDW-10 microcomputer-controlled electronic universal tensile testing machine to test Its super elastic. by tensile test curve (see figure 1 g) It can be seen that when the cold deformation is 27%, the superelasticity has reached the best ( figure 1 g).

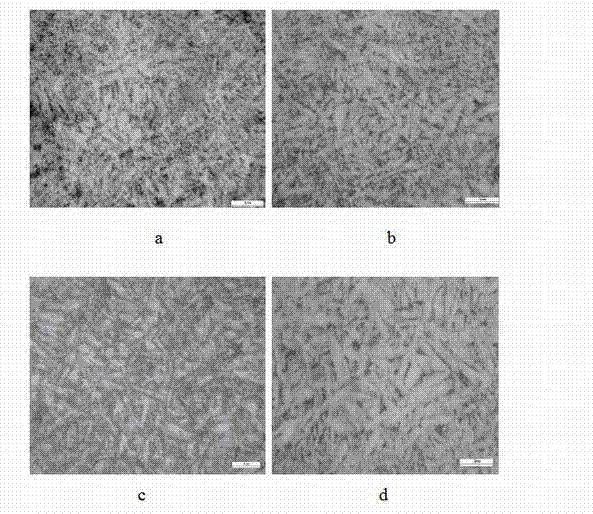

[0025] At the same time, alloy wires with different amounts of cold deformation are inlaid on the XQ-2 sample inlaying machine. The inlaid wires are polished, polished, and corroded with corrosive agents. The etchant is hydrofluoric acid: nitric acid = 1:2.5. The corroded samples were observed under an optical microscope. It can be seen that the cold deformation produces a martensite modification inside the NiTiV. When the cold deformation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com