Warping device

A technology of guiding device and supporting device, applied in warping machine, textile and papermaking, rewinding machine, etc., can solve the problem of occupying production time and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

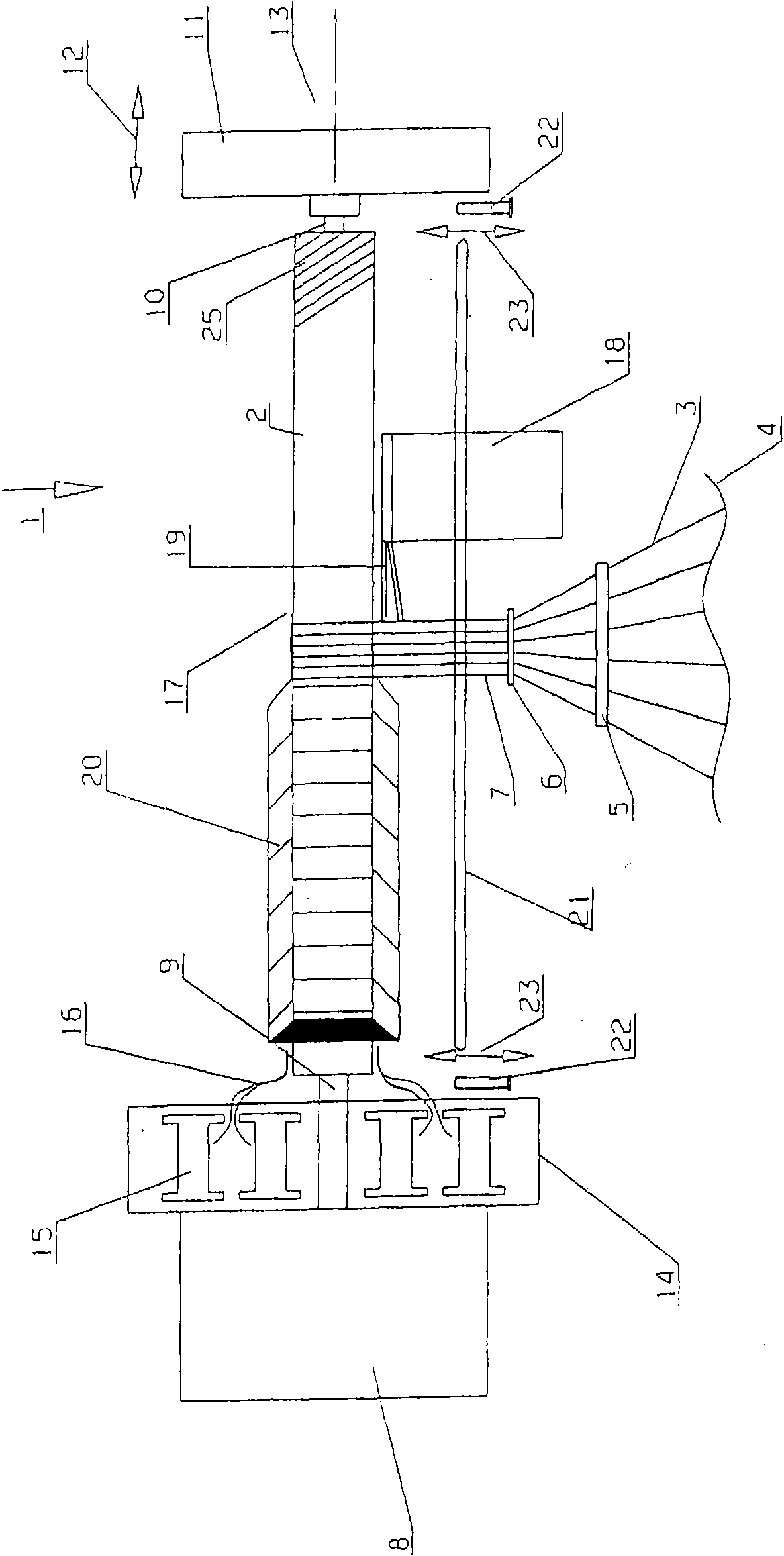

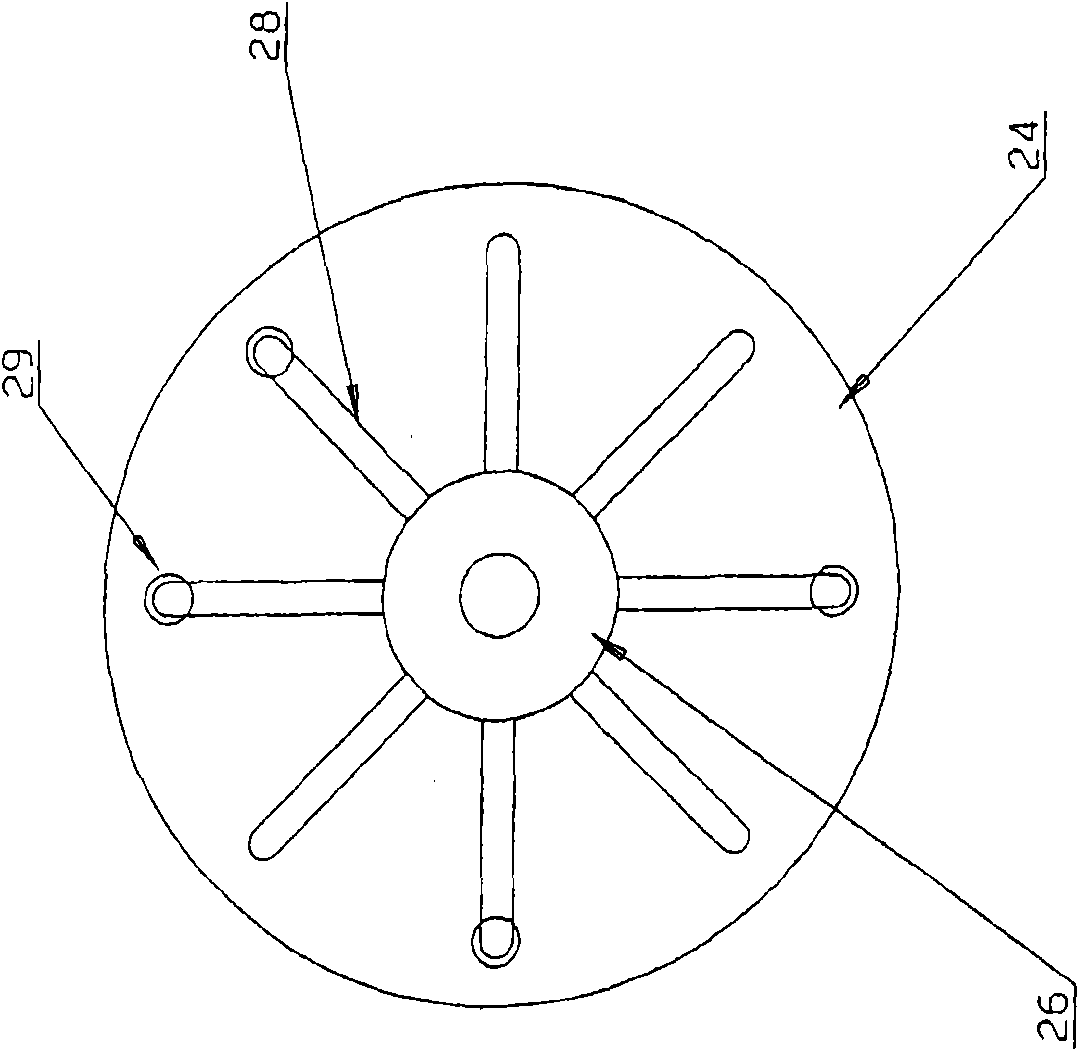

[0021] figure 1 A warping device 1 is shown in extremely simplified form, comprising a creel designed as a warp beam 2 , on which creel a yarn 3 unwound from a creel 4 is wound. The yarn 3 is passed through a cross-twisting device 5 and then through a warping reed 6 in which the yarn is finally combined into a yarn tape 7 .

[0022] The warp beam 2 is connected to a rotary drive 8 . For this purpose, the warp beam 2 has at one axial end a warp beam carrier 9 which, by means of a follower, not shown in detail, engages in a rotationally fixed engagement with the rotary drive 8 .

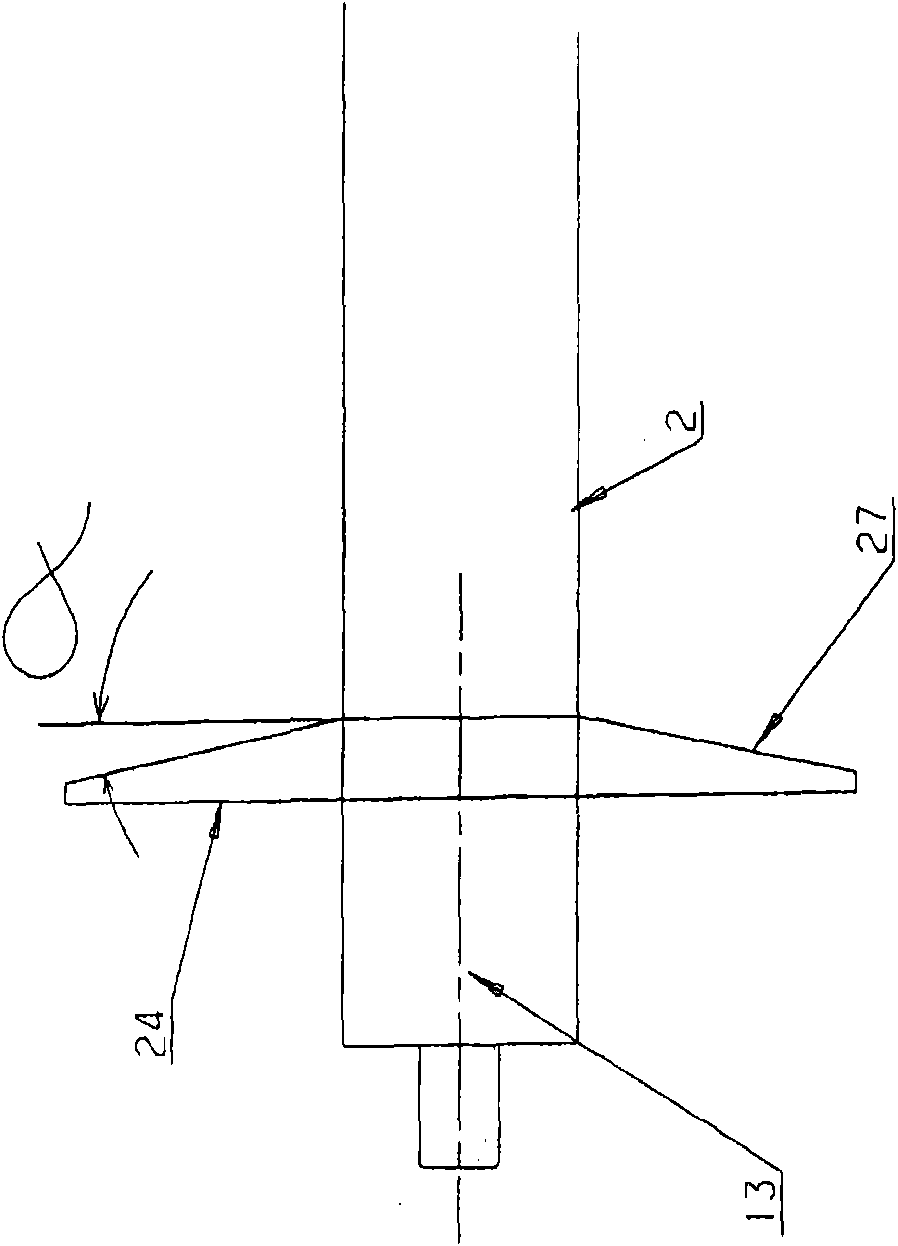

[0023] On the opposite end, the warp beam 2 has a further warp beam support 10 , which is supported in an opposing support 11 . This counter-support 11 is movable in the direction of the double arrow 12 , that is to say parallel to the axis 13 of the warp beam 2 . Thus, the warp beam 2 can firstly be brought into engagement at one end with its warp beam support 9 with the rotary drive 8, and then th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com