Hot rolling method of cold-rolling low-carbon non-oriented electrical steel

An oriented electrical steel, low-carbon and low-silicon technology, which is applied in the field of hot rolling of cold-rolled low-carbon, low-silicon non-oriented electrical steel, can solve the problem of restricting the production, promotion, high cost, Long development cycle and other problems, to achieve the effect of stable rolling state, lower production cost, and simplified control method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

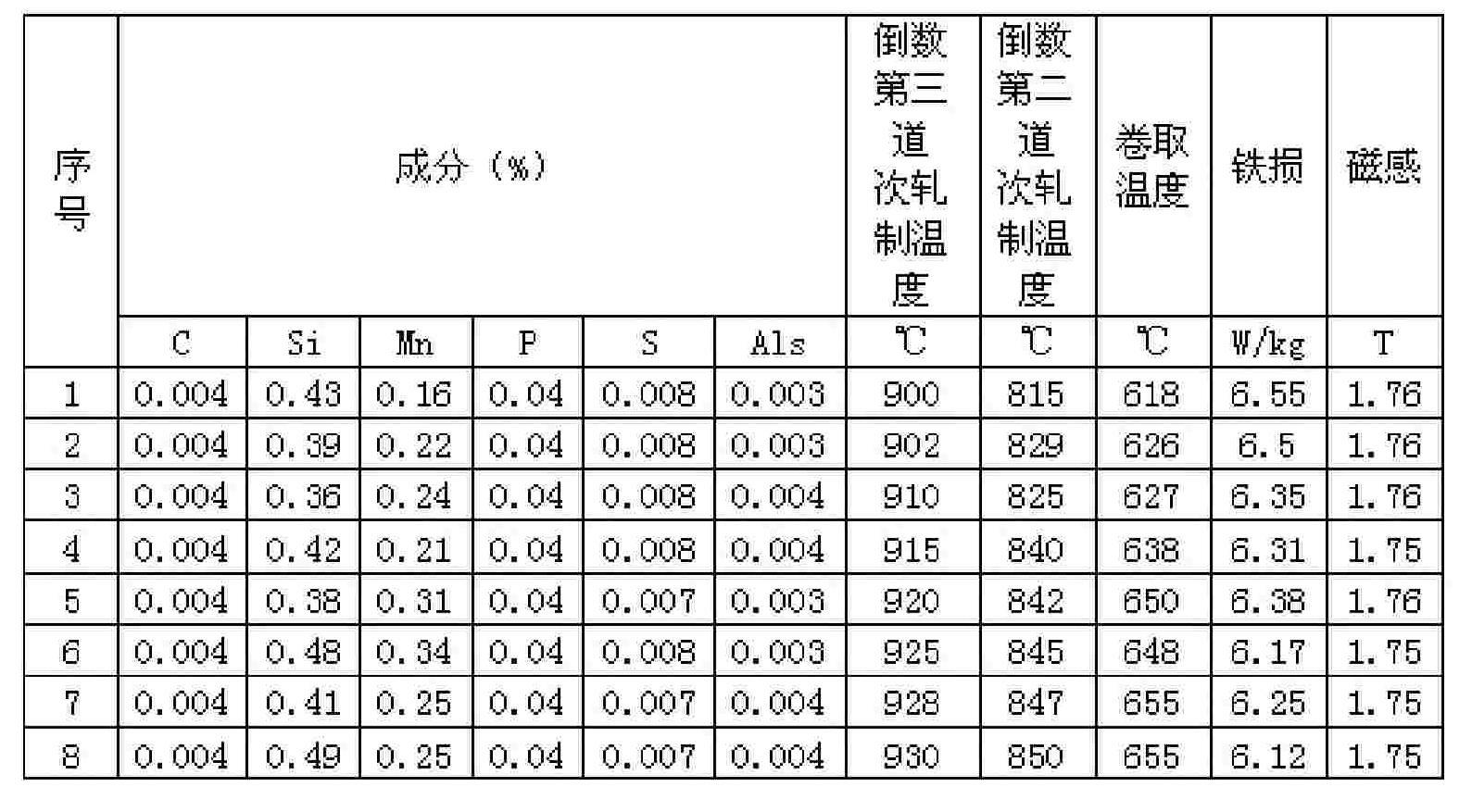

[0021] In the non-oriented electrical steel production line of a certain factory, the engineering test of cold-rolled low-carbon and low-silicon non-oriented electrical steel was carried out according to the hot rolling method of the present invention, and other processes except hot rolling were implemented according to existing requirements.

[0022] Specifically, the finishing rolling unit is a six-stand finishing rolling unit capable of six-pass finishing rolling, the temperature range of starting rolling is the same as the existing one, and the above-mentioned forced cooling is set between the penultimate pass and the penultimate pass. During the period, forced cooling is cooling water cooling.

[0023] Limited by the performance of specific equipment, in order to ensure that the starting rolling temperature meets the requirements and the processing capacity of each pass before the penultimate pass, and the slab can be directly cooled by forced cooling between the penultima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com