Steel coil feeding and speed controlling device of full-automatic uncoiler

An uncoiler, fully automatic technology, applied in the direction of coiling strip, transportation and packaging, thin material handling, etc., can solve the problem that the feeding speed of steel coil cannot be accurately controlled in real time, the influence of uncoiling, leveling quality life, and the sagging range of steel plate Unwinding and other problems, to achieve the effect of stable work, preventing unwinding or punching, and avoiding unwinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following are specific embodiments of the present invention and the accompanying drawings to further describe the technical solutions of the present invention, but the present invention is not limited to these embodiments.

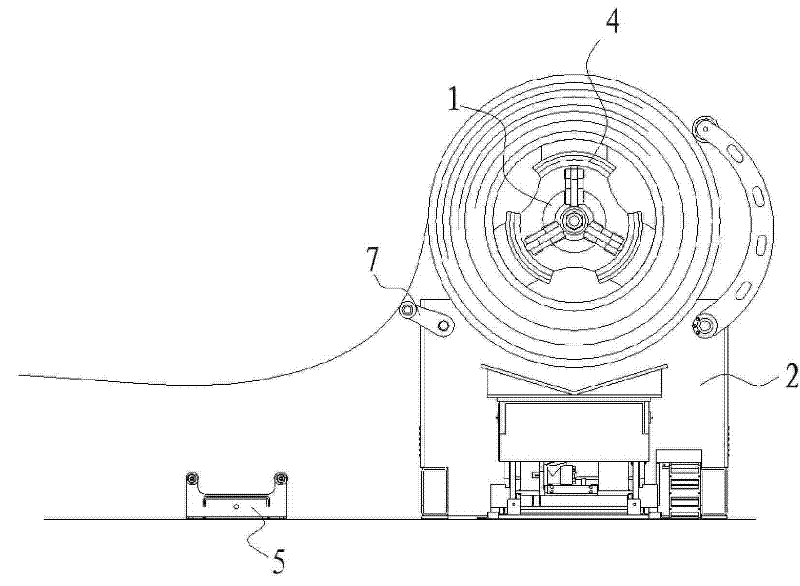

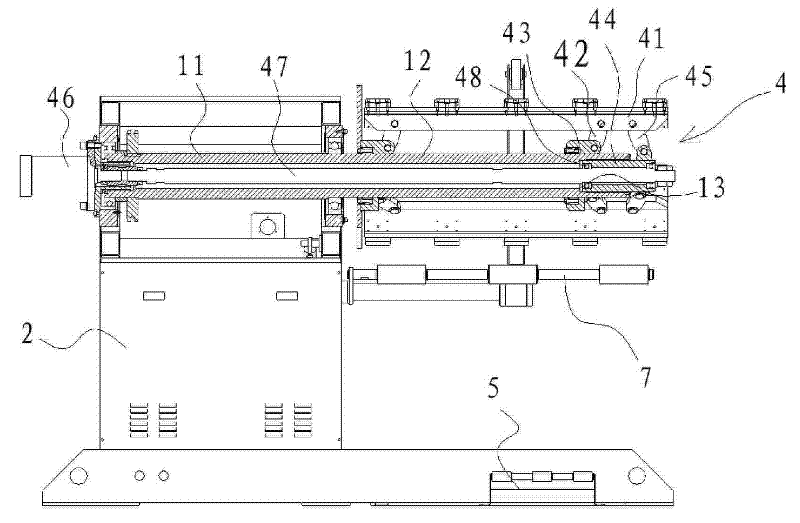

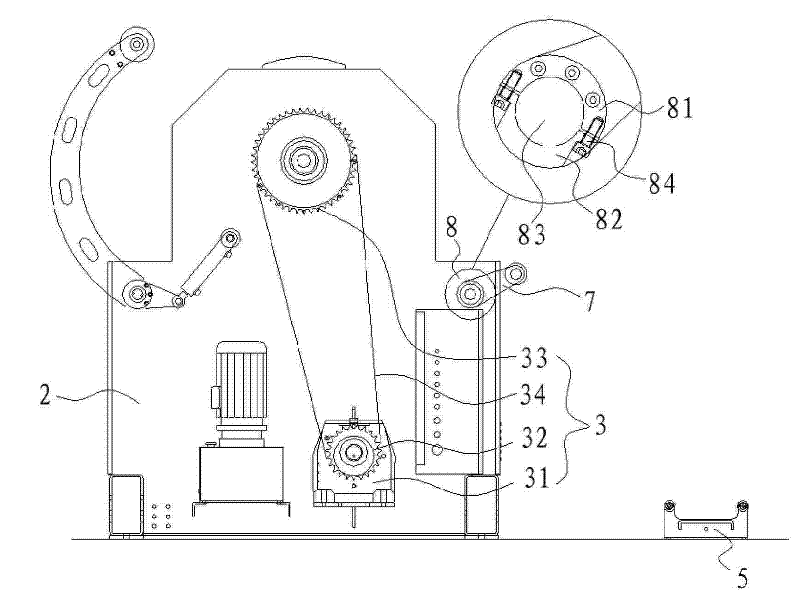

[0024] like figure 1 , figure 2 and image 3 The steel coil feeding and speed control device of the automatic uncoiler includes a rotating shaft 1 having a mounting section 11 and a cantilever section 12. The mounting section 11 of the rotating shaft 1 is arranged in the base 2 of the automatic uncoiler and can be connected to the base 2 of the automatic uncoiler. The power mechanism 3 that drives the rotating shaft 1 to rotate in the forward and reverse directions is connected. The power mechanism 3 includes a deceleration motor 31 with a braking device, a driving sprocket 32 fixed on the deceleration motor 31 and a driven sprocket 33 fixed on the installation section 11. A chain 34 is sleeved on the driving sprocket 32 and the driven sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com